Building construction method

A building construction and construction technology, applied in the field of building construction, can solve the problems of less research on building strength, anti-corrosion, anti-bacterial and impact resistance, affecting the density and strength of foamed concrete, and comprehensive performance to be improved, etc., to achieve anti-bacterial and anti-corrosion. Stable and durable performance, high sterilization efficiency, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

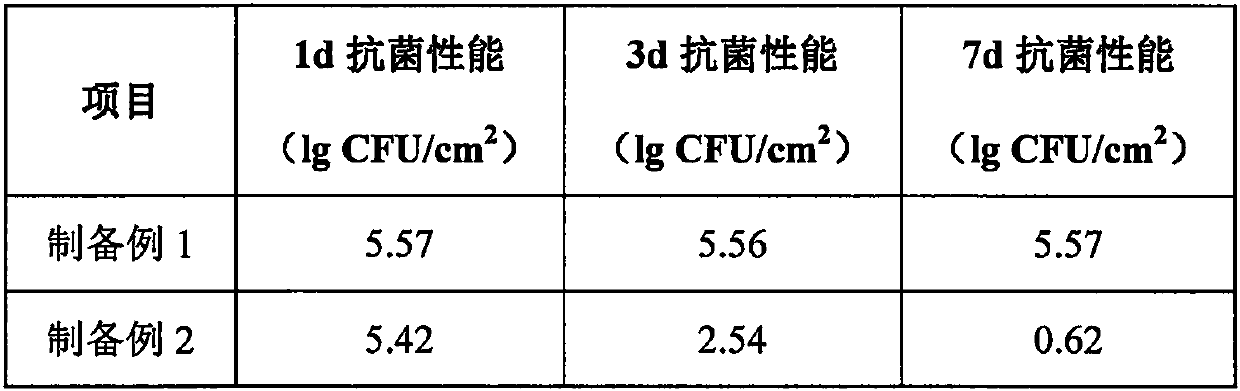

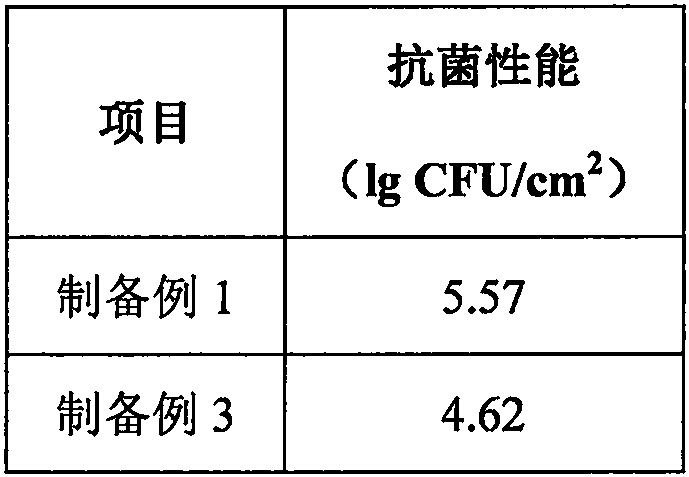

preparation example 1

[0111] The preparation method of the modularized building insulation material comprises the following steps:

[0112] (1) get the cumene hydroperoxide of 2 weight parts, be dissolved in the distilled water of 20 weight parts at normal temperature, get the first initiator solution;

[0113] (2) Take 8 parts by weight of polyvinyl alcohol, dissolve it in 18 parts by weight of distilled water at normal temperature, add 5 parts by weight of tricalcium phosphate to the above solution, and ultrasonically for 10-20 minutes to obtain a stable dispersion;

[0114] (3) get the sodium dodecylbenzenesulfonate of 3 weight parts, be dissolved in the distilled water of 12 weight parts at normal temperature, obtain emulsion;

[0115] (4) 4.5 parts by weight of styrene, 0.5 parts by weight of DMAE-BC and 0.6 parts by weight of foaming agent are added to the first initiator solution of 4.4 parts by weight of step (1), and then 6.2 parts by weight of step (2) Disperse the stable liquid and 5 pa...

preparation example 2

[0125] The preparation method in which the antibacterial agent is added to the polystyrene building material in a blending manner comprises the following steps:

[0126] (1) Take 8 parts by weight of polyvinyl alcohol, dissolve it in 18 parts by weight of distilled water at normal temperature, add 5 parts by weight of tricalcium phosphate to the above solution, and ultrasonically 10-20 minutes to obtain a stable dispersion;

[0127] (2) get the sodium dodecylbenzenesulfonate of 0.6 weight part, be dissolved in the distilled water of 12 weight parts at normal temperature, obtain emulsion;

[0128] (3) get the cumene hydroperoxide of 2 weight parts, be dissolved in the distilled water of 20 weight parts at normal temperature, obtain the first initiator solution;

[0129] (4) Get 4.5 parts by weight of styrene and 0.5 parts by weight of DMAE-BC, add 22 parts by weight of distilled water, add 0.6 parts by weight of foaming agent, and stir evenly to obtain antibacterial modified po...

preparation example 3

[0139] In this preparation example, except that the antibacterial agent is methacryloyloxyethyl-n-hexadecyl-dimethylammonium bromide (DMAE-CB), other preparation methods and reagent consumption are the same as those of preparation example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com