A construction method for cast-in-place slabs

An on-site pouring and floor slab technology, which is applied to the preparation of building components on site, construction, floor slabs, etc., can solve the problems of changes in the thickness of the protective layer, affect the flatness of the floor, and affect the quality of the floor, so as to reduce subsequent processes and save labor costs , Improve the effect of pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

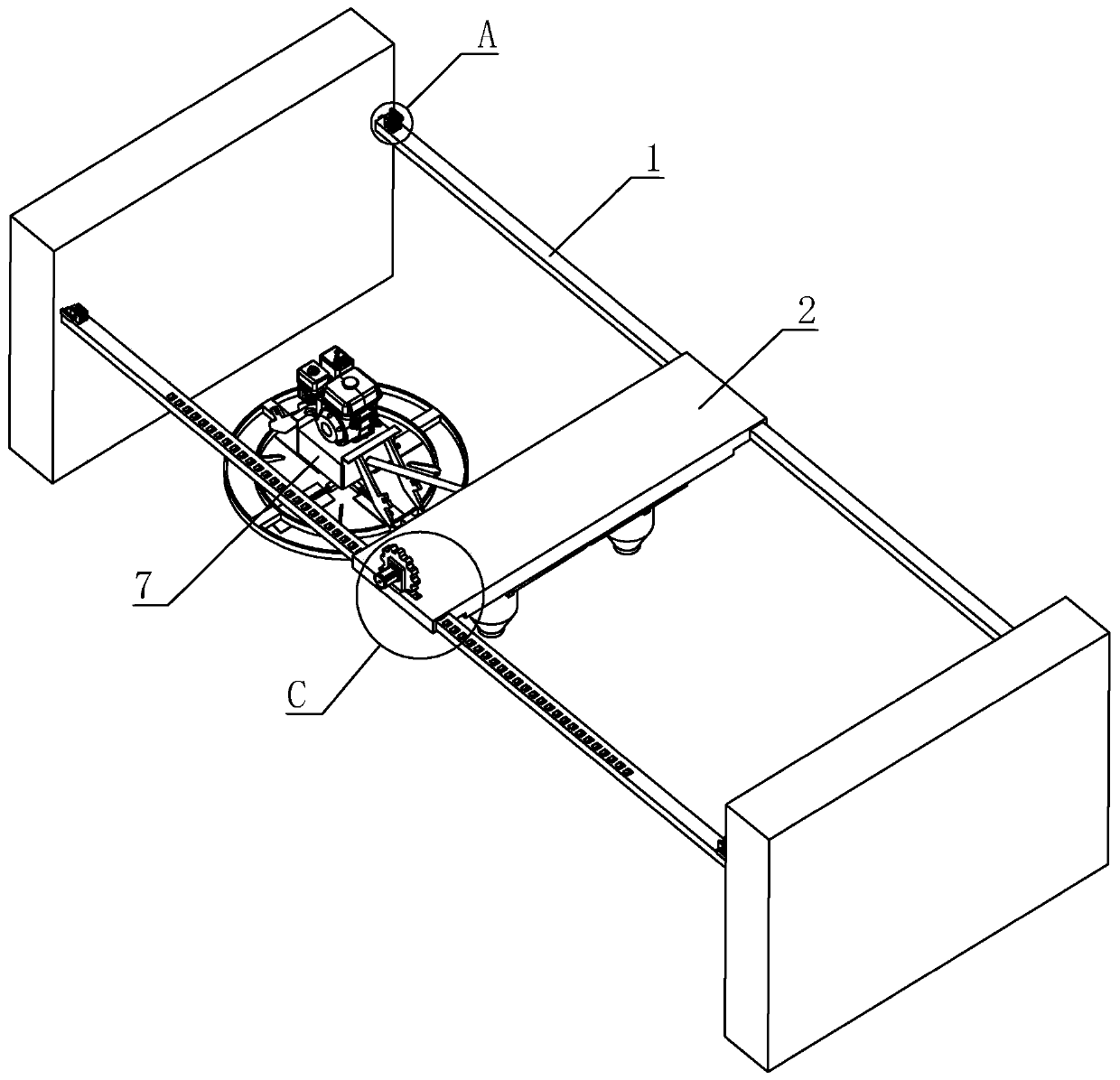

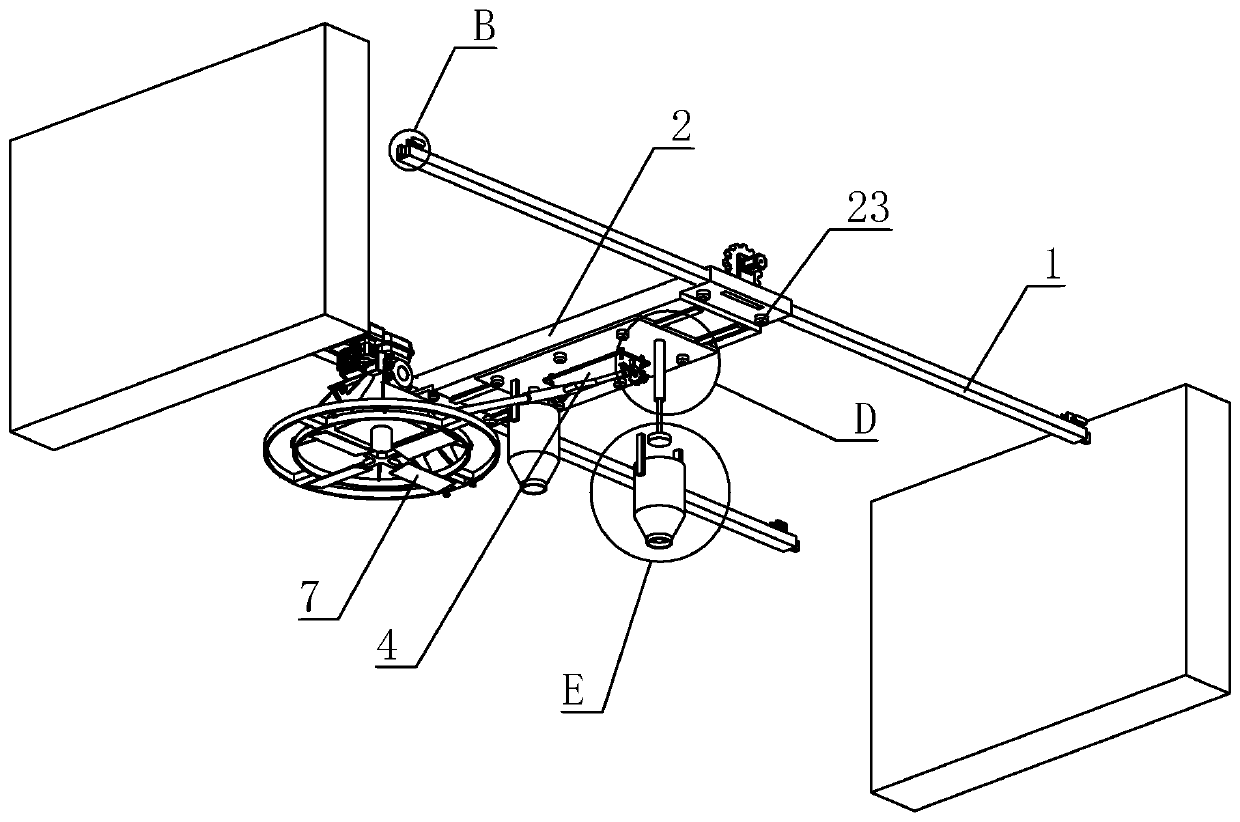

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

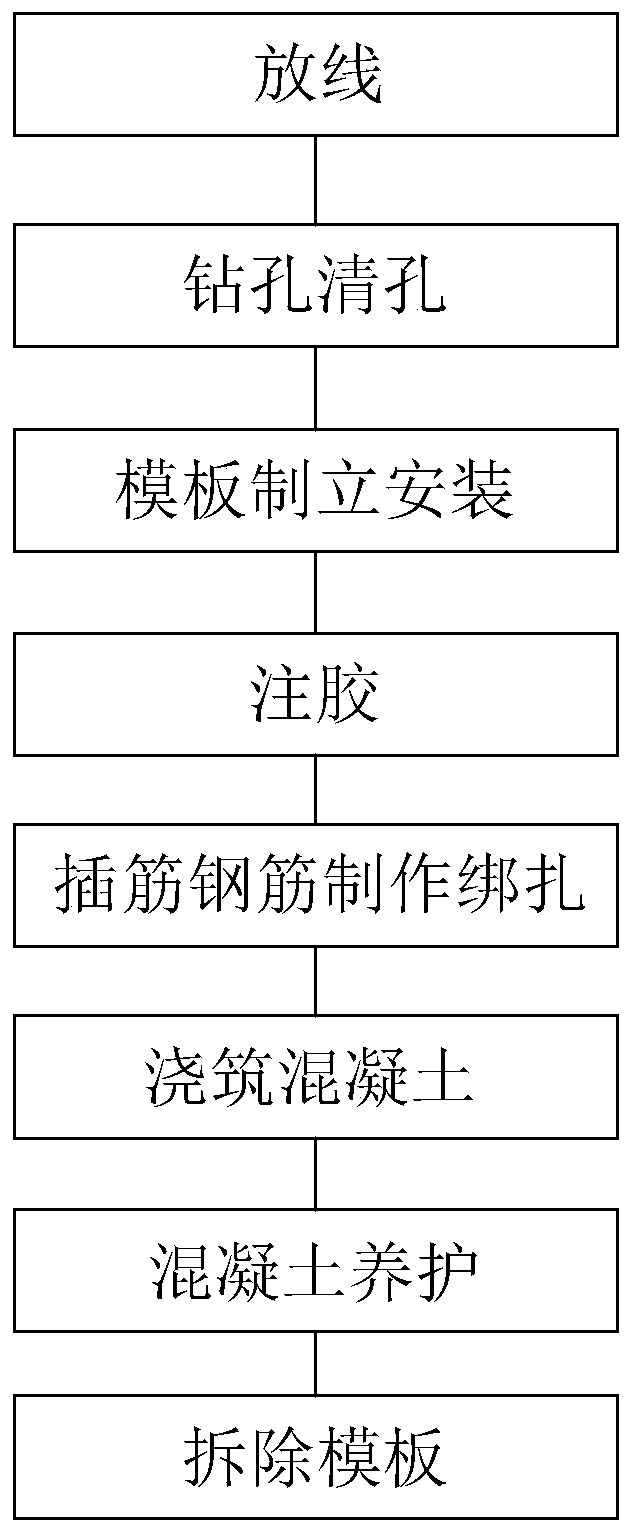

[0051] A construction method for cast-in-place slabs, cf. figure 1 , including the following steps:

[0052] Sp1: Set off the thread, according to the size data, use the ink fountain to bounce the thread on the wall;

[0053] Sp2: Drill and clean the hole, use an electric drill to make a hole on the wall, and then use a hair dryer to blow off the dust in the hole;

[0054] Sp3: Formwork erection and installation, set up a shelf, and install the floor formwork on the shelf;

[0055] Sp4: Glue injection, inject glue into the hole;

[0056] Sp5: Inserting steel bars to make binding, inserting steel bars into the holes, and binding the external steel bars to fix the external steel bars;

[0057] Sp6: Pouring concrete, pouring concrete on formwork, covering steel bars, and troweling;

[0058] Sp7: Concrete curing, watering and curing several times a day for a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com