Preparation method of sulfhydryl coal gangue and application thereof in soil remediation

A technology of mercapto-based coal gangue and coal gangue, which is applied in the field of material modification and soil heavy metal pollution restoration, can solve problems such as air, soil, water pollution and geological disasters, damage to the ecological environment, and impact on natural landscapes. The effect of low requirements and strong chemical adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of present embodiment mercapto coal gangue is as follows:

[0027] (1) Crushing the gangue through a 200-mesh sieve;

[0028] (2) Then acidify in a sulfuric acid solution with a mass fraction of 20% to remove metals in coal gangue, wash with deionized water until neutral, and then dry for later use;

[0029] (3) Add 10g of acidified gangue to 100ml of sulfuric acid solution with a volume fraction of 50%, stir at 80°C for 30 minutes, add potassium permanganate in multiple batches, totaling 1g, and deionize the oxidized gangue Wash with water until neutral, dry for later use;

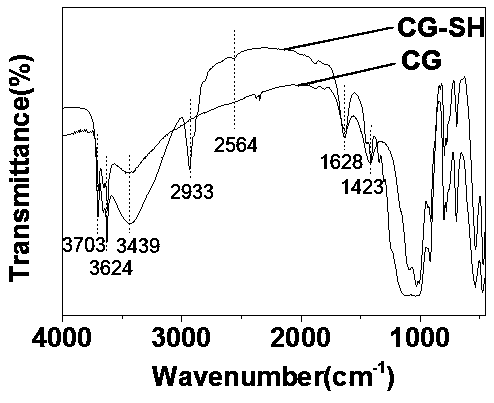

[0030] (4) Then put 10g of oxidized coal gangue into a 250ml round bottom flask with 50ml of methanol, and stir for 30min, add 10g of ethylenediamine, gradually raise the temperature to 75°C, and reflux for 2h; add 20ml of 3-mercaptopropyltrimethyl Oxysilane solution (volume ratio of 3-mercaptopropyltrimethoxysilane to methanol = 1:1), the mass of 3-mercaptopropyltrimethoxy...

Embodiment 2

[0035] The preparation method of present embodiment mercapto coal gangue is as follows:

[0036] (1) Crushing the gangue through a 200-mesh sieve;

[0037] (2) Then acidify in a nitric acid solution with a mass fraction of 10% to remove metals in coal gangue, wash with deionized water until neutral, and dry for later use;

[0038] (3) Add 10g of acidified gangue to 100ml of sulfuric acid solution with a volume fraction of 50%, stir at 70°C for 30 minutes, add potassium permanganate in multiple batches, totaling 1g, and deionize the oxidized gangue Wash with water until neutral, dry for later use;

[0039](4) Then put 10g of oxidized coal gangue into a 250ml round bottom flask with 50ml of methanol, and stir for 30min, add 10g of ethylenediamine, gradually raise the temperature to 70°C, and reflux for 2h; add 20ml of 3-mercaptopropyl trimethyl Oxysilane solution (volume ratio of 3-mercaptopropyltrimethoxysilane to methanol = 1:1), the mass of 3-mercaptopropyltrimethoxysilane ...

Embodiment 3

[0041] The preparation method of present embodiment mercapto coal gangue is as follows:

[0042] (1) Crushing the gangue through a 200-mesh sieve;

[0043] (2) Then acidify in a hydrochloric acid solution with a mass fraction of 30% to remove metals in coal gangue, wash with deionized water until neutral, and then dry for later use;

[0044] (3) Add 10g of acidified gangue to 100ml of sulfuric acid solution with a volume fraction of 50%, stir at 90°C for 30 minutes, add potassium permanganate in multiple batches, totaling 1g, and deionize the oxidized gangue Wash with water until neutral, dry for later use;

[0045] (4) Then put 10g of oxidized coal gangue into a 250ml round bottom flask with 50ml of methanol, and stir for 30min, add 10g of ethylenediamine, gradually raise the temperature to 80°C, and reflux for 2h; add 20ml of 3-mercaptopropyltrimethyl Oxysilane solution (volume ratio of 3-mercaptopropyltrimethoxysilane to methanol = 1:1), the mass of 3-mercaptopropyltrimet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com