Cerium-titanium oxide mesoporous millimeter-sphere ozone catalyst and preparation method and application thereof

A catalyst and oxide technology, applied in the field of water treatment, can solve the problems of complex preparation process, generation of organic waste liquid, and high preparation cost, and achieve the effects of enriching pore structure, promoting mineralization and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

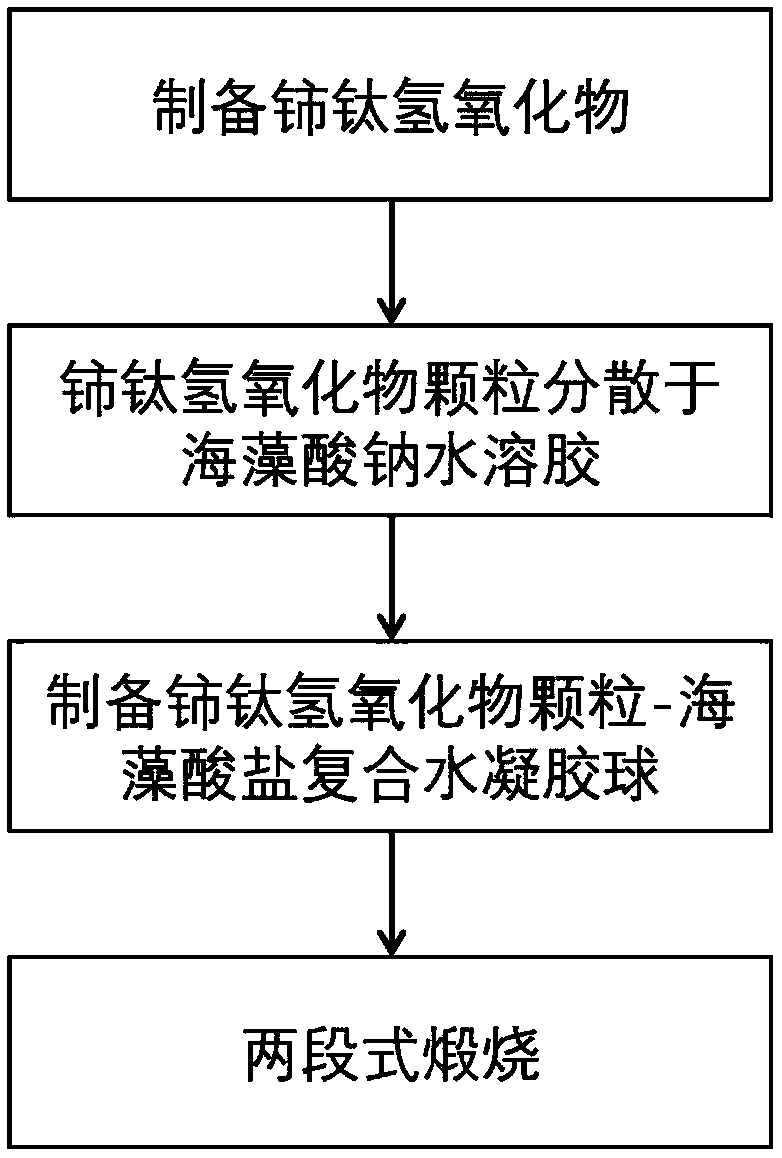

[0054] The preparation steps of cerium titanium oxide mesoporous millimeter sphere ozone catalyst in the present embodiment are as follows figure 1 Shown:

[0055] (1) Preparation of cerium titanium hydroxide: at room temperature, 7.5mmol TiOSO 4 (Titanyl sulfate) and 7.5mmol (NH 4 ) 2 Ce(NO 3 ) 6 (Ceric ammonium nitrate) was dissolved in 40mL deionized water to form a solution, then the cerium solution was added to the titanium solution and mixed, and then added together to the 120mL aqueous solution containing 14g urea to obtain the mixed aqueous solution E; at this time, the cerium in the mixed aqueous solution E The total concentration of titanium is 0.075mol / L, the concentration of urea is 1.2mol / L, and the ratio of urea concentration to the total concentration of cerium titanium (cerium element and titanium element) is 16;

[0056] Heat the aqueous solution E in a water bath at 90-95°C for 8 hours, and magnetically stir at a speed of 300rpm to precipitate cerium and...

Embodiment 2

[0065] The preparation steps of cerium titanium oxide mesoporous millimeter sphere ozone catalyst in the present embodiment are as follows figure 1 Shown:

[0066] (1) Preparation of cerium-titanium hydroxide: at room temperature, 11.25 mmol of TiOSO 4 (Titanyl sulfate) and 3.75mmol of (NH 4 ) 2 Ce(NO 3 ) 6 (Ceric ammonium nitrate) was dissolved in 40mL deionized water to form a solution, then the cerium solution was added to the titanium solution and mixed, and then added together to the 120mL aqueous solution containing 14g urea to obtain the mixed aqueous solution E; at this time, the cerium in the mixed aqueous solution E The total concentration of titanium is 0.075mol / L, the concentration of urea is 1.2mol / L, and the ratio of urea concentration to the total concentration of cerium titanium (cerium element and titanium element) is 16;

[0067] Heat the aqueous solution E in a water bath at 90-95°C for 8 hours, and magnetically stir at a speed of 300rpm to precipitate ...

Embodiment 3

[0074] The preparation steps of cerium titanium oxide mesoporous millimeter sphere ozone catalyst in the present embodiment are as follows figure 1 Shown:

[0075] (1) Preparation of cerium-titanium hydroxide: at room temperature, 3.75 mmol of TiOSO 4 (Titanyl sulfate) and 11.25mmol of (NH 4 ) 2 Ce(NO 3 ) 6 (Ceric ammonium nitrate) was dissolved in 40mL deionized water to form a solution, then the cerium solution was added to the titanium solution and mixed, and then added together to the 120mL aqueous solution containing 14g urea to obtain the mixed aqueous solution E; at this time, the cerium in the mixed aqueous solution E The total concentration of titanium is 0.075mol / L, the concentration of urea is 1.2mol / L, and the ratio of urea concentration to the total concentration of cerium titanium (cerium element and titanium element) is 16;

[0076] Heat the aqueous solution E in a water bath at 90-95°C for 8 hours, and magnetically stir at a speed of 300rpm to precipitate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com