Regenerated micropowder alkaline residue clinker-free gel material and preparation method thereof

A technology of regenerated micro-powder and gel materials, applied in cement production, etc., can solve problems such as low recycling rate of construction waste, increased environmental burden, unfavorable development, etc., and achieve significant industrial practical value, qualified stability, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

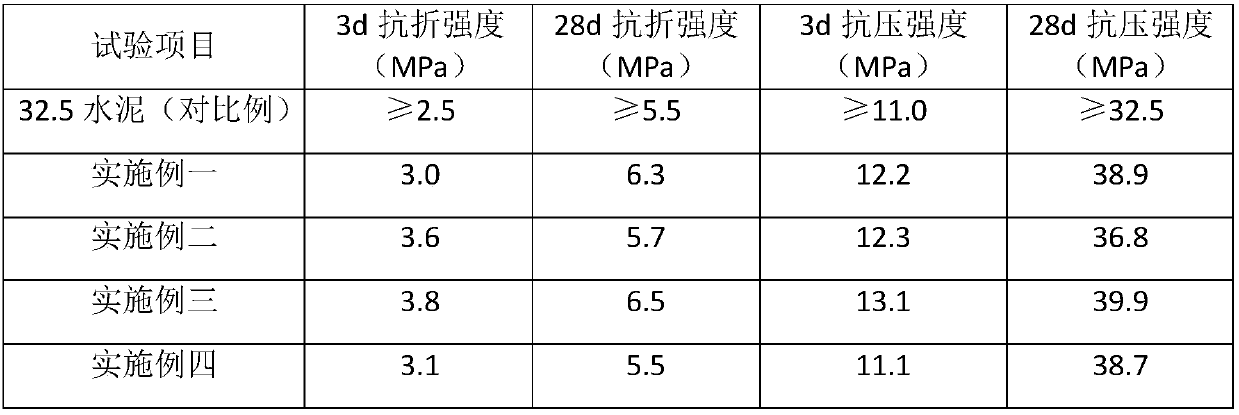

Examples

Embodiment 1

[0023] In this embodiment, a regenerated micropowder alkali slag-free clinker gel material includes the following components by weight percentage: slag micropowder meeting the S95 cement standard: 35%, regenerated micropowder: 35%, alkali slag micropowder: 20%, desulfurized gypsum: 5%, admixture content: 5%. Wherein the admixture is a mixture of acidic activator A and basic activator B, the mass ratio of the activator A and activator B is 1:1, and the regenerated micropowder alkali slag has no clinker gel material The specific surface area of each component reaches 400m 2 / kg.

[0024] In this embodiment, the above-mentioned regenerated micropowder uses brick powder, cement and lime in construction waste as raw materials, and the regenerated brick powder and cement-lime mixed micropowder with a particle size not greater than 0.08mm is produced through a dedicated complete set of equipment for a combined grinding system. Make the specific surface area 400m 2 / kg, and dried...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, especially in that:

[0038] In this embodiment, a regenerated micropowder alkali slag-free clinker gel material includes the following components by weight percentage: slag micropowder meeting the S95 cement standard: 30%, regenerated micropowder: 45%, alkali slag micropowder: 15%, desulfurized gypsum: 5%, admixture content: 5%. Wherein said admixture is the mixture of acidic activator A and basic activator B, the mass ratio of said activator A and activator B is 2:3, and the regenerated micropowder alkali slag has no clinker gel material The specific surface area of each component reaches 400m 2 / kg.

[0039] In this embodiment, the above-mentioned regenerated micropowder uses brick powder, cement and lime in construction waste as raw materials, and the regenerated brick powder and cement-lime mixed micropowder with a particle size not greater than 0.08mm is produced through a dedicated complete set of equipme...

Embodiment 3

[0050] This embodiment is basically the same as the previous embodiment, and the special features are:

[0051] In this embodiment, a regenerated micropowder alkali slag-free clinker gel material includes the following components by weight percentage: slag micropowder meeting the S95 cement standard: 45%, regenerated micropowder: 30%, alkali slag micropowder: 15%, desulfurized gypsum: 5%, admixture content: 5%. Wherein said admixture is the mixture of acidic activator A and basic activator B, the mass ratio of said activator A and activator B is 2:3, and the regenerated micropowder alkali slag has no clinker gel material The specific surface area of each component reaches 400m 2 / kg.

[0052] In this embodiment, the above-mentioned regenerated micropowder uses brick powder, cement and lime in construction waste as raw materials, and the regenerated brick powder and cement-lime mixed micropowder with a particle size not greater than 0.08mm is produced through a dedicated co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com