Plant polysaccharide extraction device and method for extracting Bletilla striata polysaccharide

A Bletilla striata polysaccharide and extraction device technology, which is applied in the field of Bletilla striata polysaccharide extraction, can solve the problems of low extraction rate and cumbersome operation of plant polysaccharides, and achieve the effect of increasing the dissolution rate and improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

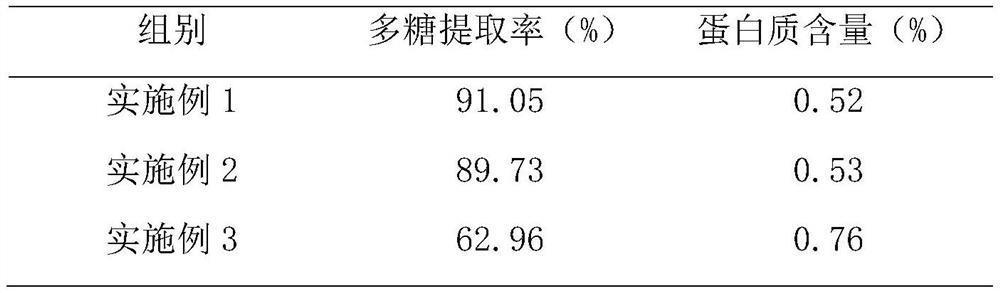

Embodiment 1

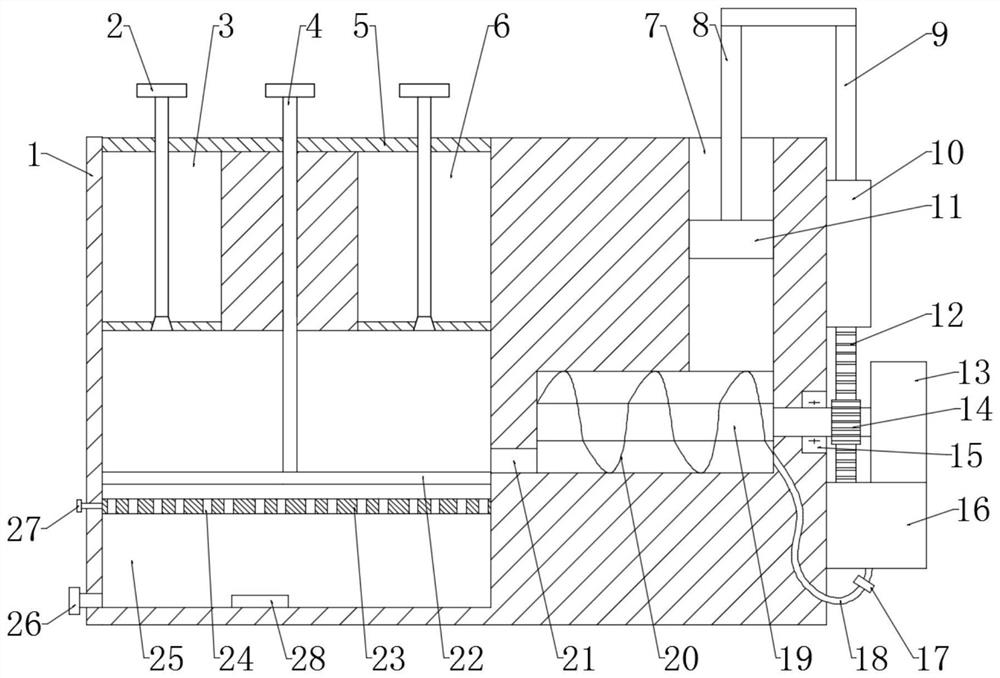

[0023] A plant polysaccharide extraction device is used to extract the method of bletilla striata polysaccharide, comprising the following steps:

[0024] Step 1: Put Bletilla striata from the feeding hole 7, start the motor, and control the feeding speed to 11kg / h; at the same time, open the water control valve 17 to keep the ratio of material to liquid at 1:10;

[0025] Step 2: during the delivery of Bletilla striata, put protease and cellulase into loading plate 23 every 15min, when throwing in protease and cellulase, stir the Bletilla striata material slag evenly by stirring bar 22; The weight ratio is 1:70;

[0026] Step 3: keep the heating temperature of the heating sheet 28 at 38°C;

[0027] Step 4: After the bletilla striata material slag completely enters the loading plate 23 for 2 hours, rotate the loading plate 23 to make the bletilla striata material slag all fall into the bottom; the bletilla striata material slag falls and then stands still for 3 hours;

[0028...

Embodiment 2

[0031] A plant polysaccharide extraction device is used to extract the method of bletilla striata polysaccharide, comprising the following steps:

[0032] Step 1: Put Bletilla striata from the feeding hole 7, start the motor, control the feeding speed to 12kg / h; open the water control valve 17 at the same time, and keep the ratio of material to liquid at 1:7;

[0033] Step 2: during the delivery of Bletilla striata, put protease and cellulase into carrier plate 23 every 13min, when putting in protease and cellulase, stir the Bletilla striata material slag evenly by stirring rod 22; The weight ratio is 1:80;

[0034] Step 3: keep the heating temperature of the heating sheet 28 at 40°C;

[0035]Step 4: After the bletilla striata material slag completely enters the loading plate 23 for 1 hour, rotate the loading plate 23 to make the bletilla striata material slag all fall to the bottom; the bletilla striata material slag falls and then stands still for 2 hours;

[0036] Step 5:...

Embodiment 3

[0039] A plant polysaccharide extraction device is used to extract the method of bletilla striata polysaccharide, comprising the following steps:

[0040] Step 1: Put the bletilla striata into the feeding hole 7, start the motor, and control the feeding speed to 10-12kg / h; at the same time, open the water control valve 17 to keep the material-liquid ratio at 1:10-1:7, and the bletilla striata slag is directly into the bottom of the cavity 25;

[0041] Step 2: Keep the heating temperature of the heating sheet 28 at 35-50° C.; let stand for 12-13 hours;

[0042] Step 3: Take out the material after standing in the cavity 25, add 95% ethanol under stirring state after cooling to make the alcohol content reach 60%; then stand still for 6 hours;

[0043] Step 4: Suction filter the material after standing, and then vacuum freeze-dry to obtain Bletilla striata polysaccharide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com