Gas combustion rate testing device

A technology of combustion rate and testing device, which is applied in the direction of using combustion for chemical analysis, etc., can solve the problems of no gas combustion rate testing device, and achieve the effect of simple test result collection process, good technical effect, and intuitive experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

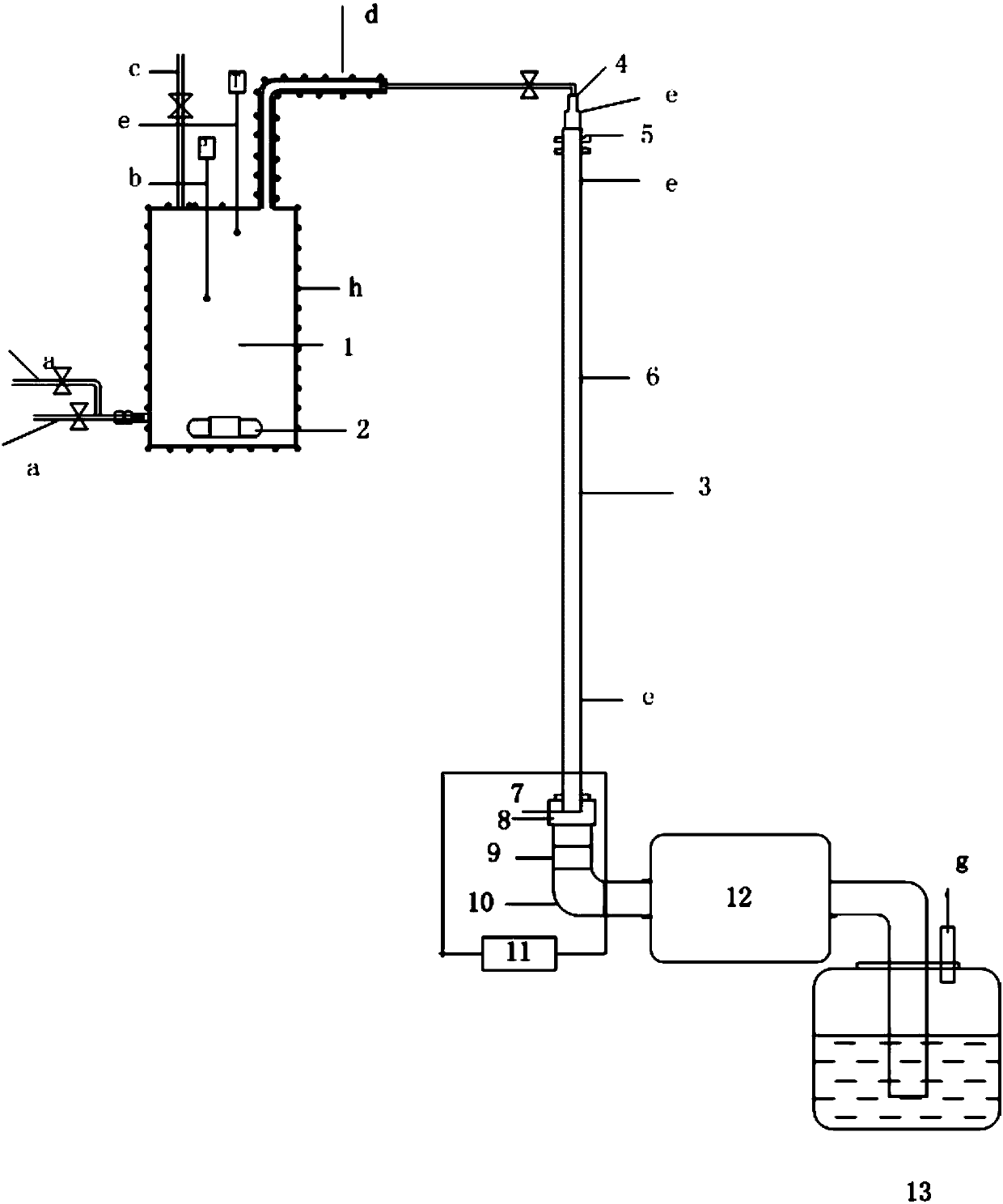

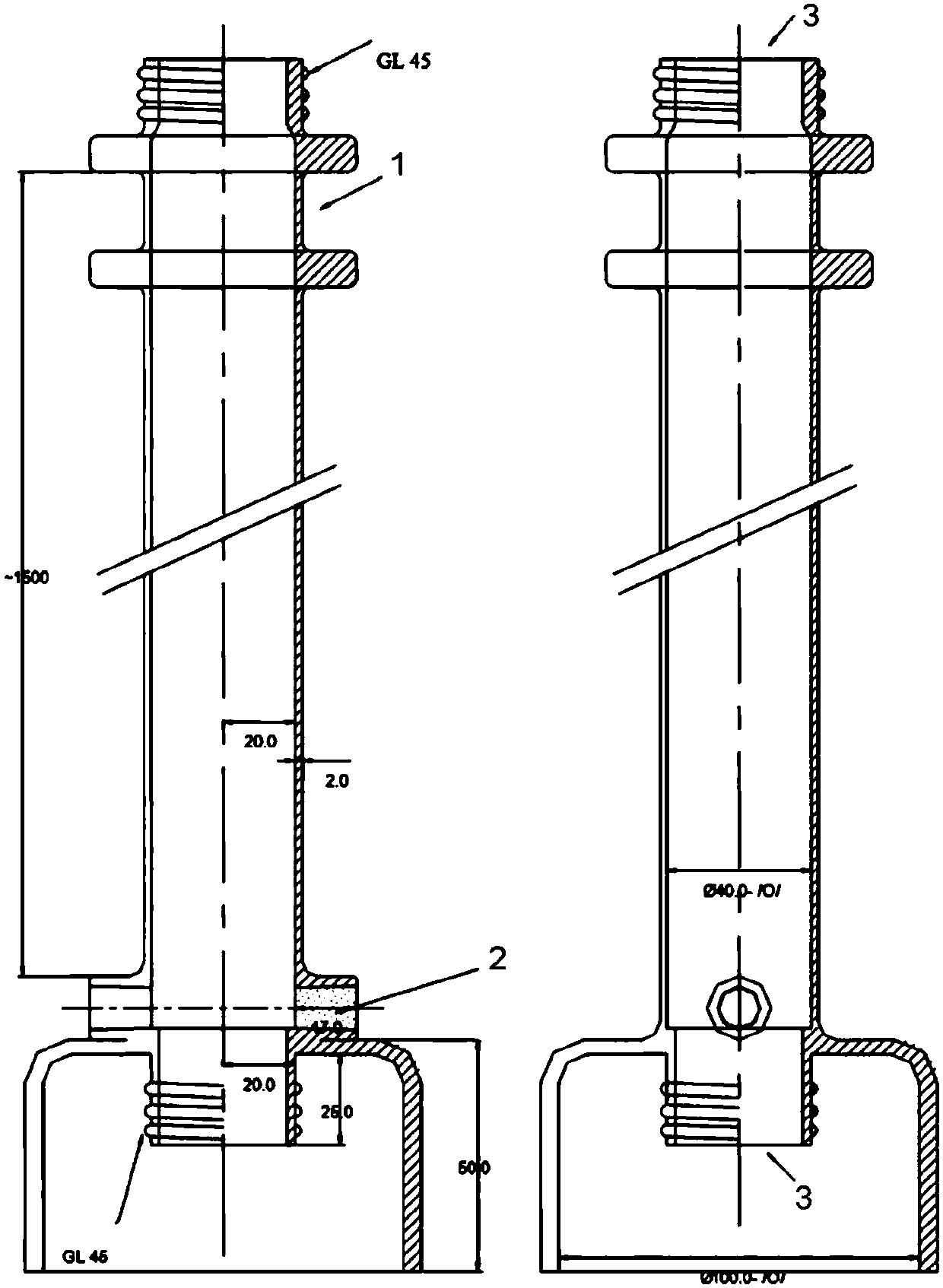

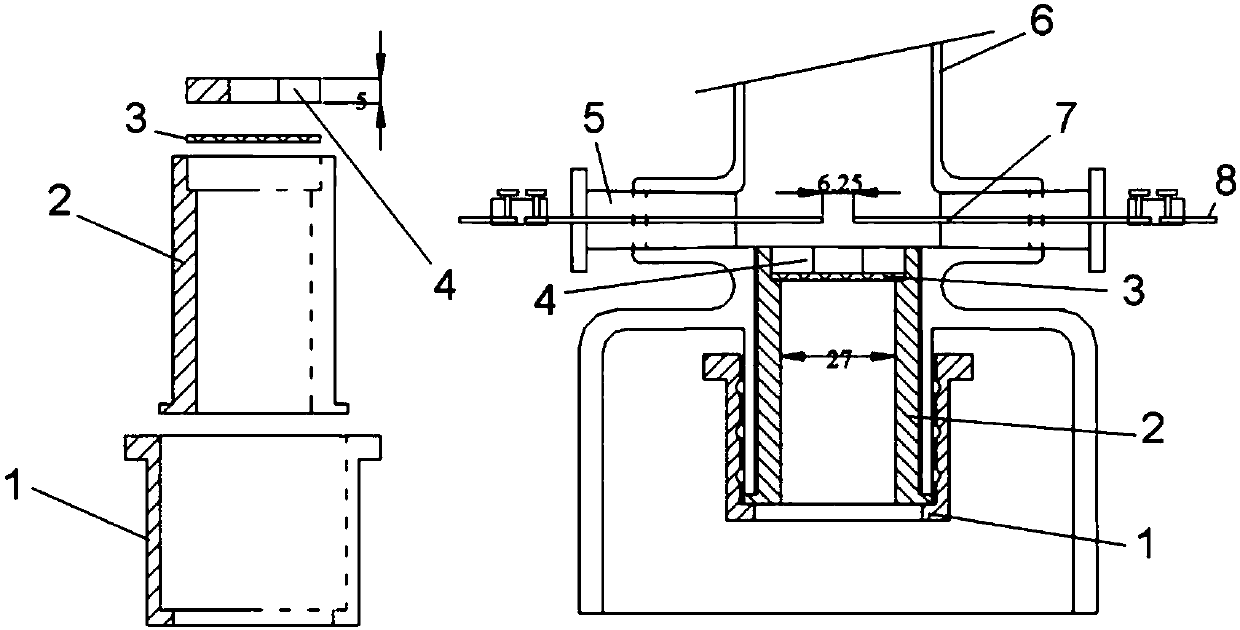

[0038] A gas burning rate testing device, such as figure 1 As shown, it mainly includes a test tube, a mixing container, an ignition system and a gas treatment system. The mixing container is connected to the gas supply tank, the bottom of the container is equipped with magnetic stirring, the outer shell of the container is equipped with a heating layer, and the top of the container is equipped with a pressure test measuring device and Vacuum pump and magnetic stirring are installed at the bottom of the mixing vessel, one end of the purge gas pipeline is connected to the mixing vessel, the other end is connected to the tube inlet of the test tube, the tube inlet is connected to the test tube through a quenching screen, and the quenching screen is installed at both ends of the test tube The outlet of the test tube is connected to the PVC tube through the quenching screen, the other end of the PVC tube is connected to the gas expansion tank, the outlet of the test tube is connect...

Embodiment 2

[0116] Adopt the device of embodiment 1, the mixed gas of certain carbon dioxide and helium, test its combustion rate, concrete implementation process is as follows:

[0117] For a mixture of hydrogen and nitrogen, test its combustion rate. The specific implementation process is as follows:

[0118] 1) The following items should be checked before the experiment starts

[0119] ①Purge the test system with dry air or nitrogen;

[0120] ② Check the gap distance between electrodes and whether it is in the middle;

[0121] ③Select the appropriate outlet pipe diameter.

[0122] 2) The mixture container and all connecting pipes and test pipes are first evacuated to below 10Pa;

[0123] 3) Turn on the magnetic stirring when starting to fill, and fill the mixed gas into the mixing container according to the corresponding partial pressure ratio. The connection should be evacuated every time a new gas is filled, and it should be closed after at least 5 minutes after filling;

[0124...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com