Micro-LED display substrate, making method thereof and display device

A technology for display substrates and manufacturing methods, which is applied to identification devices, instruments, etc., can solve problems such as uneven life length, complicated manufacturing process, and influence on display quality, and achieve the effects of ensuring uniformity, improving life, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0046] The embodiments of the present invention aim at realizing color display by fabricating RGB three-color Micro-LED arrays in the prior art. For the problem of display quality, a Micro-LED display substrate and its manufacturing method and display device are provided, which can simplify the manufacturing process of Micro-LED display substrate, ensure the uniformity of luminous intensity of different color sub-pixels, and improve the micro-LED display substrate. lifespan.

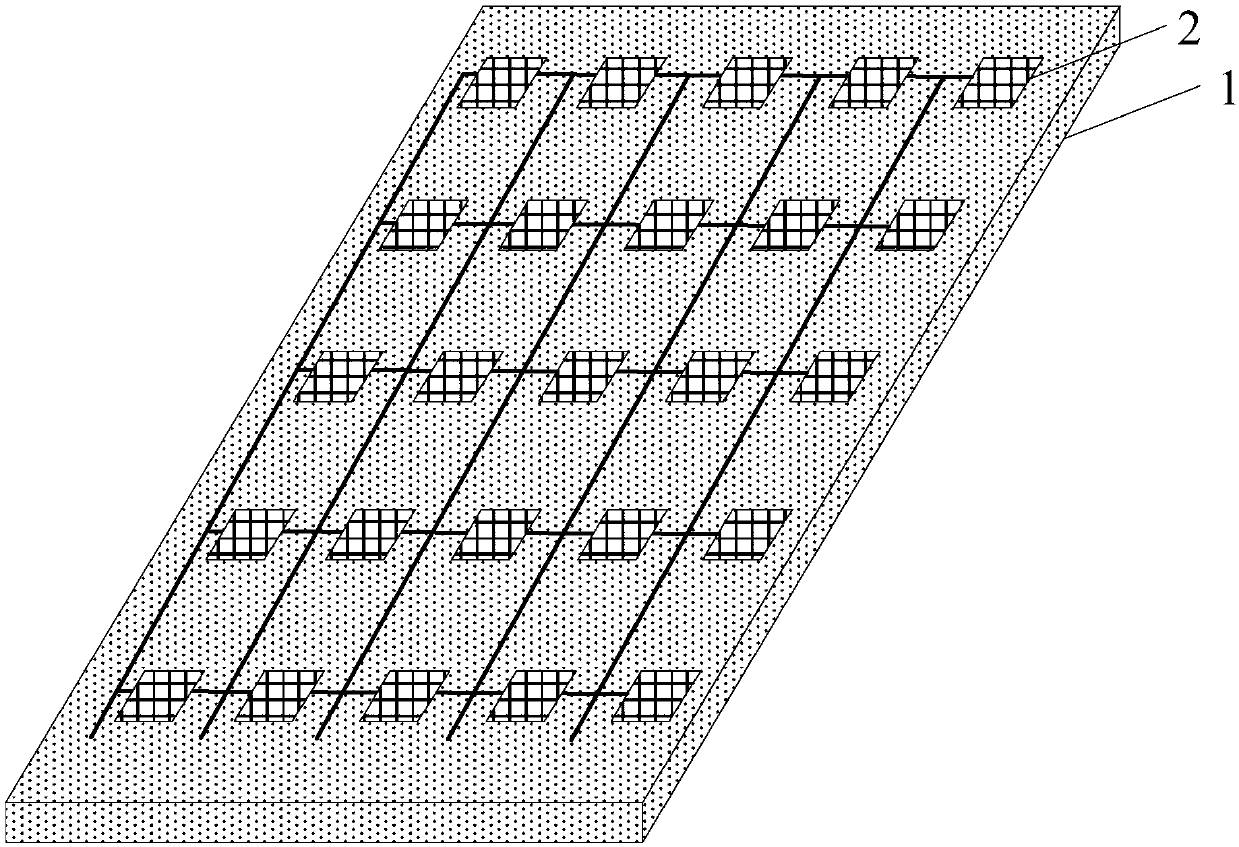

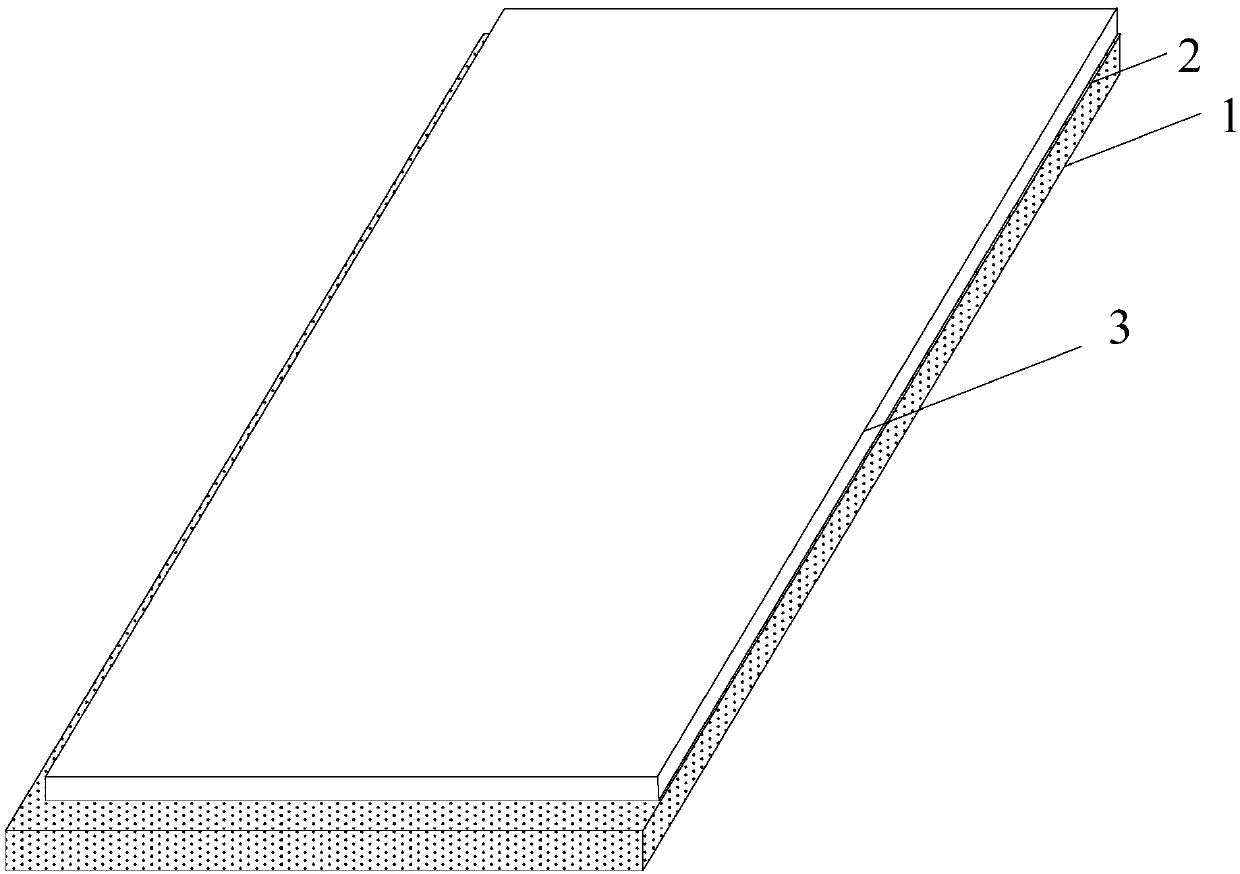

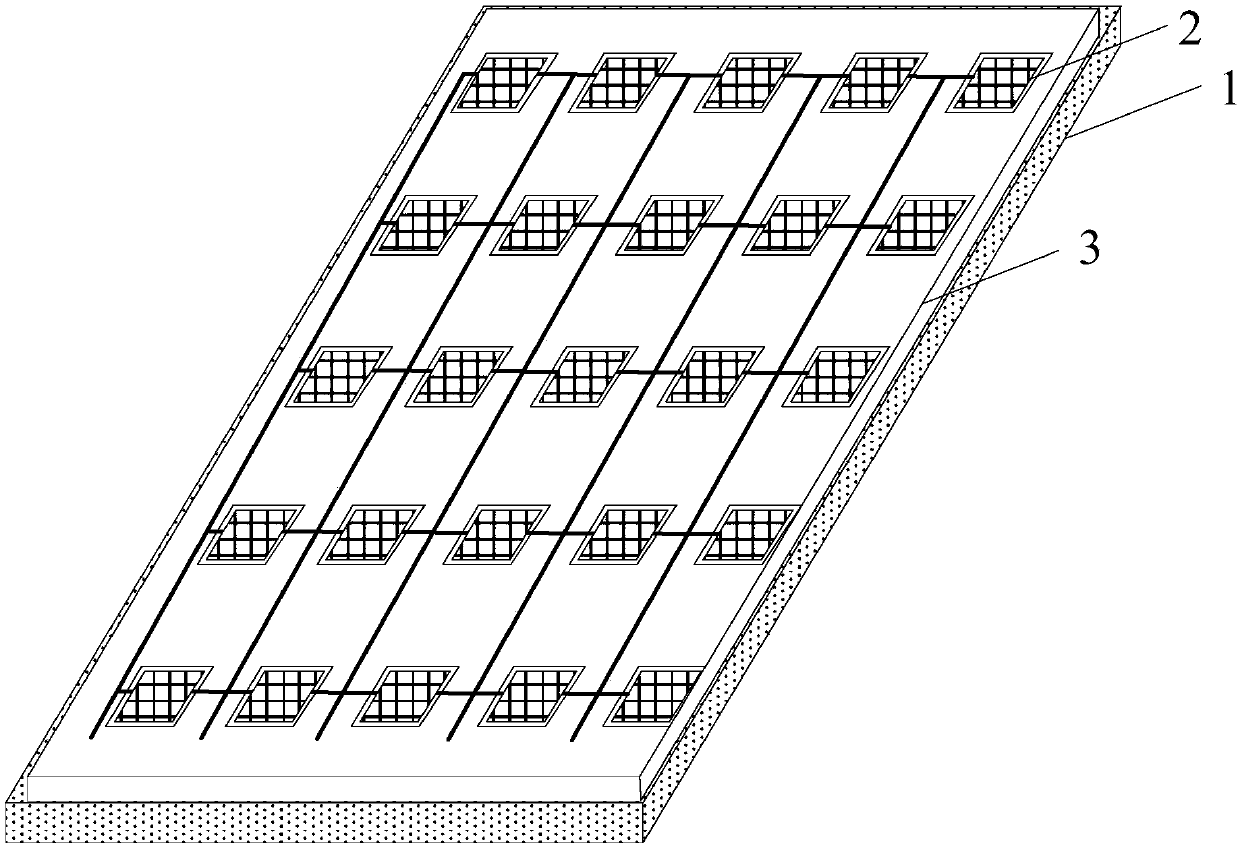

[0047] An embodiment of the present invention provides a Micro-LED display substrate, including:

[0048] circuit substrate;

[0049] A blue LED array located on the circuit substrate;

[0050] a retaining wall between adjacent LEDs, the retaining wall defines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com