Implementation method of white light LED capable of regulating color temperature, regulating color rendering index and regulating brightness

A realization method and technology of color temperature, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low color temperature, low cost, and large light attenuation, so as to reduce the conversion absorption problem, improve the light quality problem, Effect of Simplified Test Conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A method for realizing a full-spectrum white light LED, comprising the following steps:

[0066] 1) The violet LED chip coated with blue phosphor, the blue LED chip coated with cyan phosphor, the blue LED chip coated with green phosphor, the blue LED chip coated with yellow phosphor and coated The blue LED chip with red phosphor is packaged in DOB form; the purple LED chip is coated with blue phosphor to produce purple light and blue light, and the blue LED chip is coated with cyan phosphor to produce and supersaturated blue light, and the blue LED chip is coated Green phosphors produce supersaturated green light, blue LED chips coated with yellow phosphors produce supersaturated yellow light, and blue LED chips coated with red phosphors produce supersaturated red light;

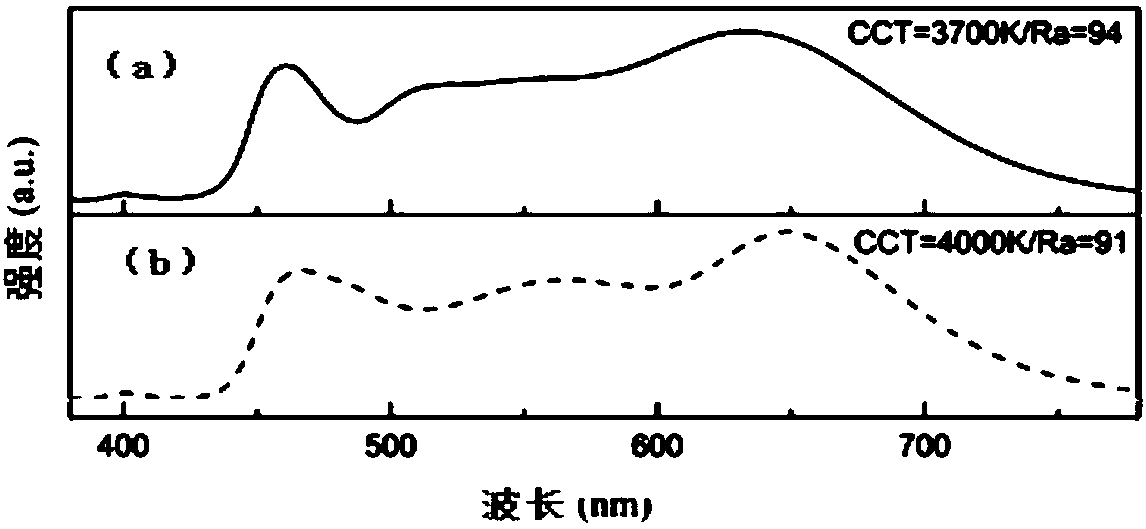

[0067] 2) Adjust the optical power of blue light, blue light, green light, yellow light and red light by individually driving the current of each LED chip, and make the purple light, blue light, blue ...

Embodiment 2

[0071] A method for realizing a full-spectrum white light LED, comprising the following steps:

[0072] 1) The purple LED chip coated with blue phosphor, the blue LED chip coated with green phosphor, the blue LED chip coated with yellow phosphor, and the blue LED chip coated with red phosphor in the form of DOB Packaging combination; blue phosphor is coated on the purple LED chip to produce supersaturated blue light, blue LED chip is coated with green phosphor to produce supersaturated green light, blue LED chip is coated with yellow phosphor to produce supersaturated yellow light, blue chip is coated Red phosphor produces supersaturated red light;

[0073] 2) Adjust the optical power of blue light, green light, yellow light and red light by individually driving the current of each LED chip, and make the blue light, green light, yellow light and red light mix to generate full-spectrum white light.

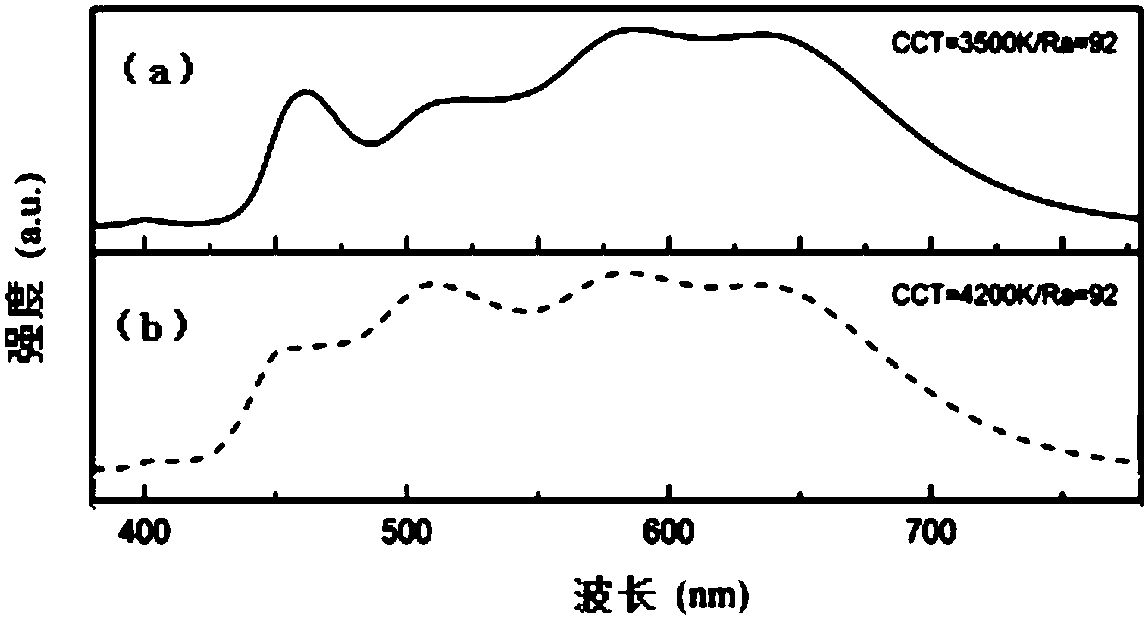

[0074] accomplish figure 2 (a) The parameters of the full-spectrum white li...

Embodiment 3

[0077] A method for realizing a full-spectrum white light LED, comprising the following steps:

[0078] 1) The violet LED chip coated with blue phosphor, the blue LED chip coated with green phosphor and the blue LED chip coated with red phosphor are combined in 5630 package; the violet LED chip is coated with blue Phosphor powder produces supersaturated blue light, blue LED chips coated with green phosphor powder produce supersaturated green light, and blue LED chips coated with red phosphor powder produce supersaturated red light;

[0079] 2) Adjust the optical power of blue light, green light and red light by individually driving the current of each LED chip, and make the blue light, green light and red light mix to produce full-spectrum white light.

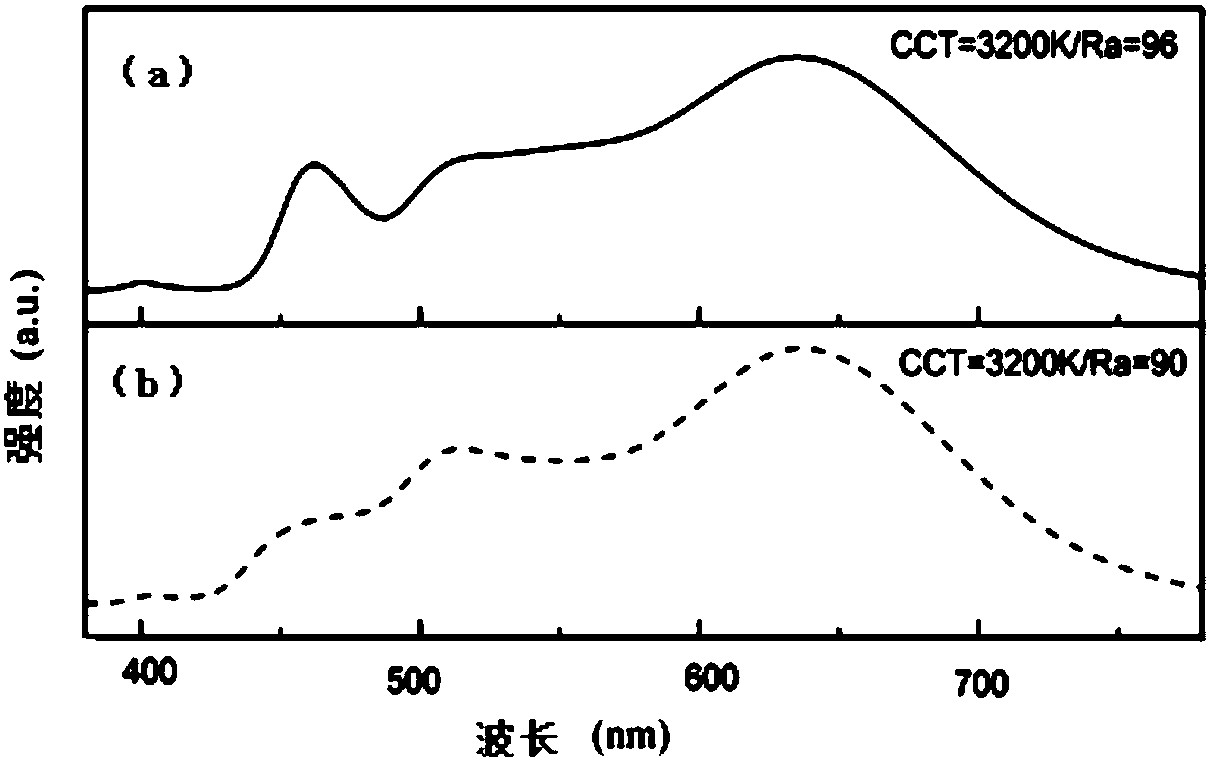

[0080] accomplish image 3 (a) The parameters of the full-spectrum white light are as follows: the wavelength of the purple LED chip is 400nm, and the wavelength of the blue LED chip is 450nm. The blue phosphor is a silicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com