Modular translational electric door driving device based on linear motor and driving control method thereof

A technology of linear motor and driving device, applied in the direction of AC motor control, electromechanical device, control system, etc., can solve the problems of inability to achieve complete adaptation, reduced control accuracy, complex system, etc., to improve the accuracy of self-learning, The effect of reducing the thrust fluctuation and reducing the installation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

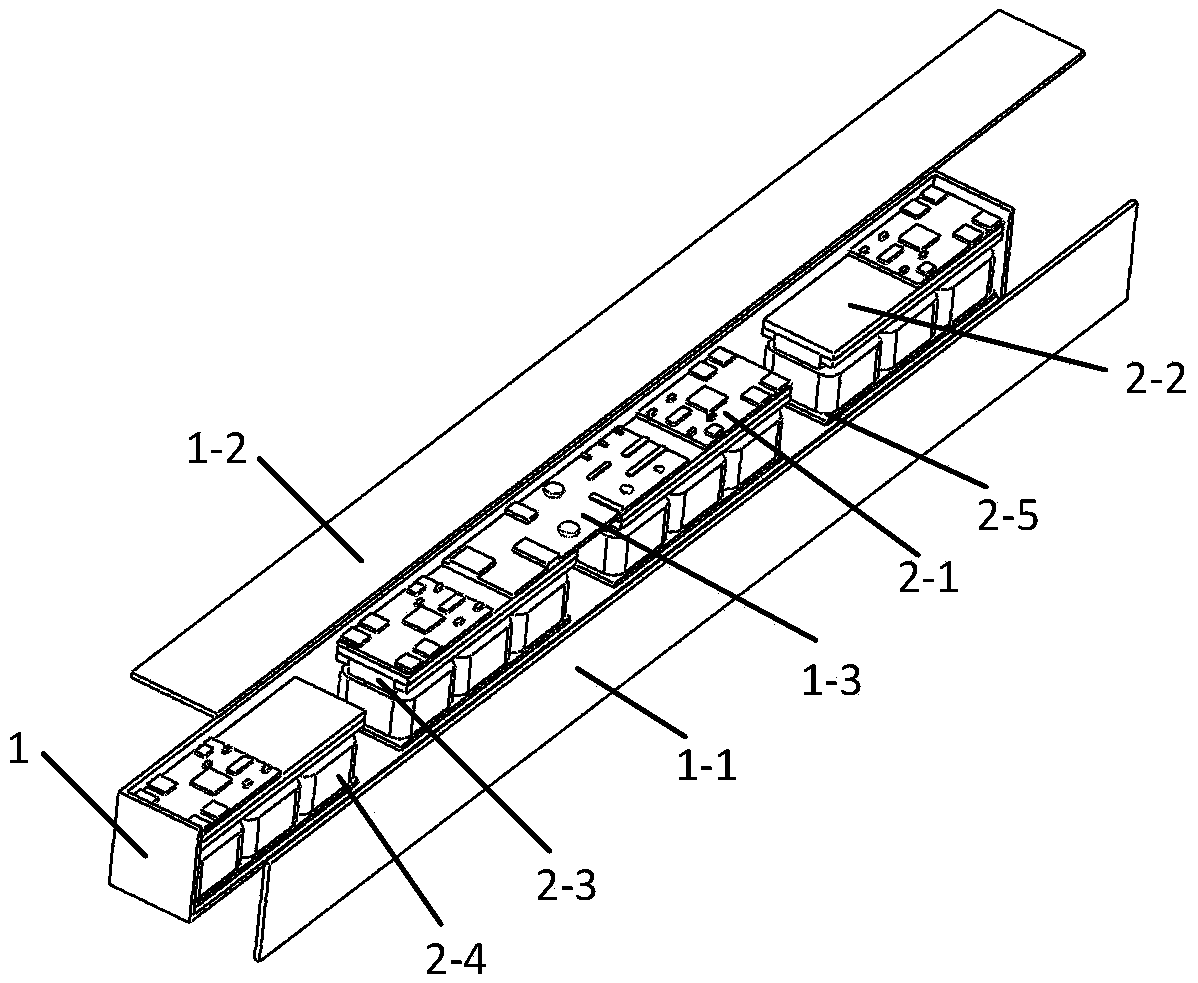

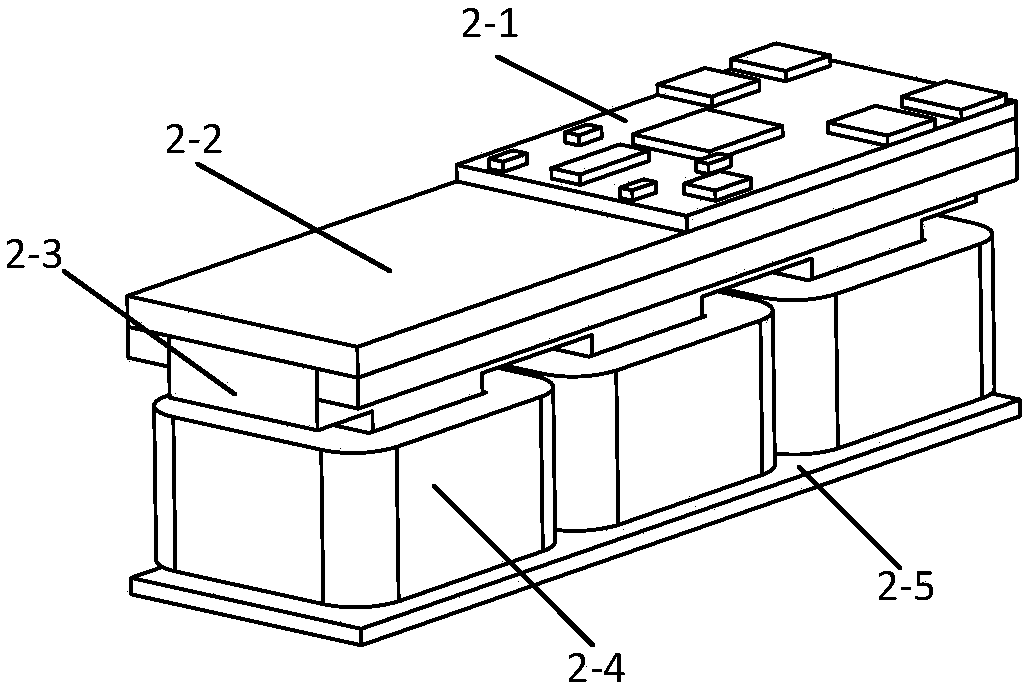

[0042] Such as Figure 4 and Figure 5 A linear motor-based modular translational electric door driving device is shown, including a stator module, a track module and a mover module;

[0043] The length of the shell 1 is 1632 mm; the shell 1 can be an aluminum alloy box, and the aluminum alloy box is sequentially provided with a position detector 2-5, a linear motor stator core 2-3, and a heat dissipation aluminum sheet 2-2. , a drive board 2-1, a control board 1-3; the winding is wound on the stator core of the motor. The linear motor stator core is composed of 24 stator core modules, each stator core module has 3 teeth, the distance between two teeth is 20mm, and the distance between every two stator core modules is 8mm ; The two ends and the middle position of the shell 1 are provided with fixing parts, and the middle fixing part is set at the middle position of the two stator core 2-3 modules, which can be welded or bolted through the fixing parts.

[0044] The mover mo...

Embodiment 2

[0049] Such as Figure 6 and Figure 7 A linear motor-based modular translational electric door driving device is shown, including a stator module, a track module and a mover module;

[0050] The length of the shell is 2880mm; the aluminum alloy box 1 is sequentially provided with a position detector 2-5, a linear motor stator core 2-3, a heat dissipation aluminum sheet 2-2, and a drive control board; The winding is wound on the stator core of the motor. The linear motor stator core is composed of 32 stator core modules, each stator core module has 3 teeth, the distance between two teeth is 27mm, and the distance between every two stator core modules is 9mm ; The two ends of the shell and the middle position are provided with fixing parts, and the middle fixing part is set at the middle position of the two stator core modules.

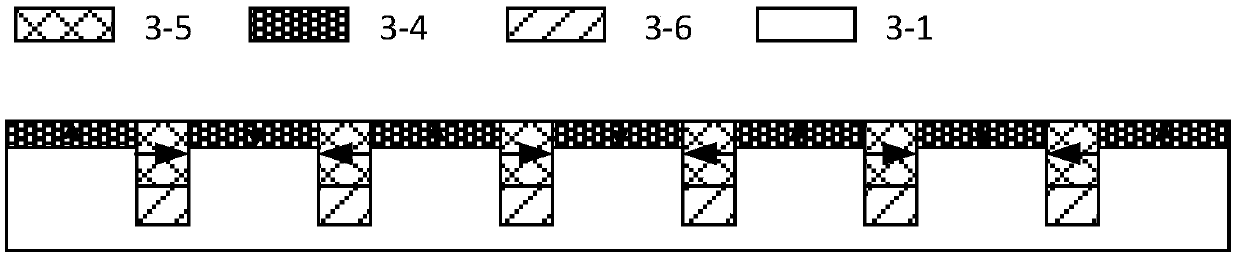

[0051] The mover module 3 includes a mover bracket 3-1 and a mover core 3-3; the mover bracket is provided with a mover core, a fixed plate, a roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com