Method for preparing sour soy milk by co-cooking technology of secondary pulp and dregs

A technology of sour soy milk and technology, which is applied in the direction of bacteria, dairy products, lactobacillus, etc. used in food preparation, can solve the problems of beany and bitter taste of sour soy milk, achieve unique flavor, reduce production cost, and uniform texture delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

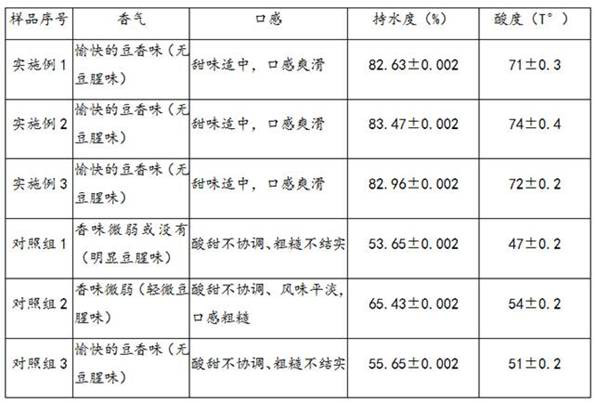

Embodiment 1

[0033] 1) Select and select high-protein soybeans with a crude protein content of not less than 40.0%, full particles, no impurities, moth-eaten and mildew, and meet the requirements of LS / T3241-2012 "Soybeans for Soymilk";

[0034] 2) Soak, rinse the soybeans twice with deionized water to remove the dust and microorganisms attached to the surface of the soybeans, and then soak the soybeans at room temperature for 10 hours (winter) according to the soybean-water ratio of 1:4 in terms of mass. The soybeans are plump, and there is no obvious hard core in the section, and the quality of wet beans is 2.3 times that of dry beans;

[0035] 3) Peel, peel the soaked soybeans with a peeler, rinse with deionized water, and set aside;

[0036] 4) Refining, by mass, in the ratio of dry soybean: water = 1:4;

[0037] 5) Cook the pulp once, suck the bean paste into the pulp cooking tank and stir evenly, cook the pulp at 115°C with micro pressure, and keep it warm for 3 minutes;

[0038] 6...

Embodiment 2

[0048] 1) Select and select high-protein soybeans with a crude protein content of not less than 40.0%, full particles, no impurities, moth-eaten and mildew, and meet the requirements of LS / T3241-2012 "Soybeans for Soymilk";

[0049] 2) Soak, rinse the soybeans twice with deionized water to remove the dust and microorganisms attached to the surface of the soybeans, and then soak the soybeans at room temperature for 12 hours (winter) according to the soybean-water ratio of 1:5 in terms of mass. The soybeans are plump, and the section has no obvious hard core, and the quality of wet beans is 2.7 times that of dry beans;

[0050] 3) Peel, peel the soaked soybeans with a peeler, rinse with deionized water, and set aside;

[0051] 4) Refining, by mass, in the ratio of dry soybean: water = 1:5;

[0052] 5) Cook the pulp once, suck the bean paste into the pulp cooking tank and stir it evenly, cook the pulp at 108°C with micro pressure, and keep it warm for 6 minutes;

[0053] 6) Onc...

Embodiment 3

[0063] 1) Select and select high-protein soybeans with a crude protein content of not less than 40.0%, full particles, no impurities, moth-eaten and mildew, and meet the requirements of LS / T3241-2012 "Soybeans for Soymilk";

[0064] 2) Soak, rinse the soybeans twice with deionized water to remove the dust and microorganisms attached to the surface of the soybeans, and then soak the soybeans at room temperature for 6 hours (summer) according to the soybean-water ratio of 1:4 in terms of mass. The soybeans are plump, and the section has no obvious hard core, and the quality of wet beans is 2.4 times that of dry beans;

[0065] 3) Peel, peel the soaked soybeans with a peeler, rinse with deionized water, and set aside;

[0066] 4) Refining, by mass, in the ratio of dry soybean: water = 1:6;

[0067] 5) Cook the pulp once, suck the bean paste into the pulp cooking tank and stir evenly, cook the pulp at 103°C with micro pressure, and keep it warm for 10 minutes;

[0068] 6) Once f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com