Preparation method for passion fruit juice beverage

A passion fruit juice and beverage technology, applied in the functions of food ingredients, food ingredients as antioxidants, food science and other directions, can solve the problem of color, aroma and taste inability to guarantee, large loss of nutrients, poor freshness and taste, etc. problem, to achieve the effect of good juice feeling, rich fruit aroma, and moderate sugar-acid ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

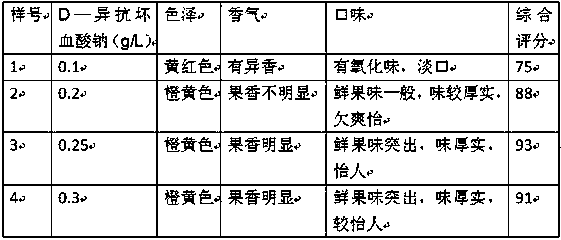

Examples

Embodiment 1

[0025] The preparation of the passion fruit drink of the present embodiment is carried out in September to December, comprises the steps:

[0026] A. First, wash the sorted passion fruit with tap water air waves, then scrub with a brush, rinse with pure water, and check out unqualified products, then squeeze the whole fruit, remove the peel, and separate the pulp, then Filter through an 80-mesh stainless steel mesh sieve to obtain 1000L of raw juice;

[0027] B. Take 400L of the original juice obtained in step A for quick freezing and storage for later use. The temperature of the frozen storage is -15°C; add purified water and auxiliary materials dissolved in pure water to the remaining 600L of original juice for deployment. The auxiliary materials are white granulated sugar, Honey, fructooligosaccharide, D-sodium erythorbate, sodium carboxymethylcellulose, the mass ratio of the added excipients to raw juice and purified water is 10:15:75; among them, white sugar, honey, fruct...

Embodiment 2

[0032] The preparation of the passion fruit drink of the present embodiment is carried out in September to December, comprises the steps:

[0033] A. First, wash the sorted passion fruit with pure water and air waves, then wash with a brush, and then check and select, dispose of unqualified products, then squeeze the whole fruit, dispose of the peel, and separate the pulp, and then Filter through an 80-mesh sieve to obtain 800L of raw juice;

[0034] B, add pure water and the adjuvant after dissolving with pure water in raw juice and prepare, and described adjuvant is white granulated sugar, honey, fructooligosaccharide, D-sodium erythorbate, sodium carboxymethyl cellulose, and the adjuvant added is the same as the original The ratio of juice to water is 11:17:72. The ratio of white sugar, honey, fructooligosaccharide, D-sodium erythorbate, and sodium carboxymethylcellulose is 9:0.6:1.1:0.03:0.27.

[0035] C. After blending the juice, pass through double filter and homogeniz...

Embodiment 3

[0039] The preparation of the passion fruit drink of the present embodiment is carried out from February to July, and comprises the steps:

[0040] A, get 400L frozen raw juice in Example 1 and thaw it, return to normal temperature, add pure water and auxiliary materials after dissolving with pure water in the original juice after thawing to prepare, described auxiliary materials are white granulated sugar, honey, low Polyfructose, D-sodium erythorbate, sodium carboxymethylcellulose, the mass ratio of the added excipients to raw juice and water is 10:15:75, white sugar, honey, fructooligosaccharides, D-sodium erythorbate, carboxymethyl cellulose The ratio of sodium methylcellulose is 8:0.5:1.0:0.025:0.25.

[0041] B. After blending the juice, it is filtered and homogenized by double filter, and the homogenization pressure is 38~40MPa;

[0042] C. Sterilize the filtrate under high temperature and high pressure, the sterilization temperature is 115°C±2°C, the sterilization pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com