A rose gold electroplating spraying process

A rose gold and gold technology, applied in coatings, devices for coating liquid on the surface, special surfaces, etc., can solve problems such as poor stability, poor metallic feeling, and strict process conditions, and achieve strong metallic texture and diverse colors , good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

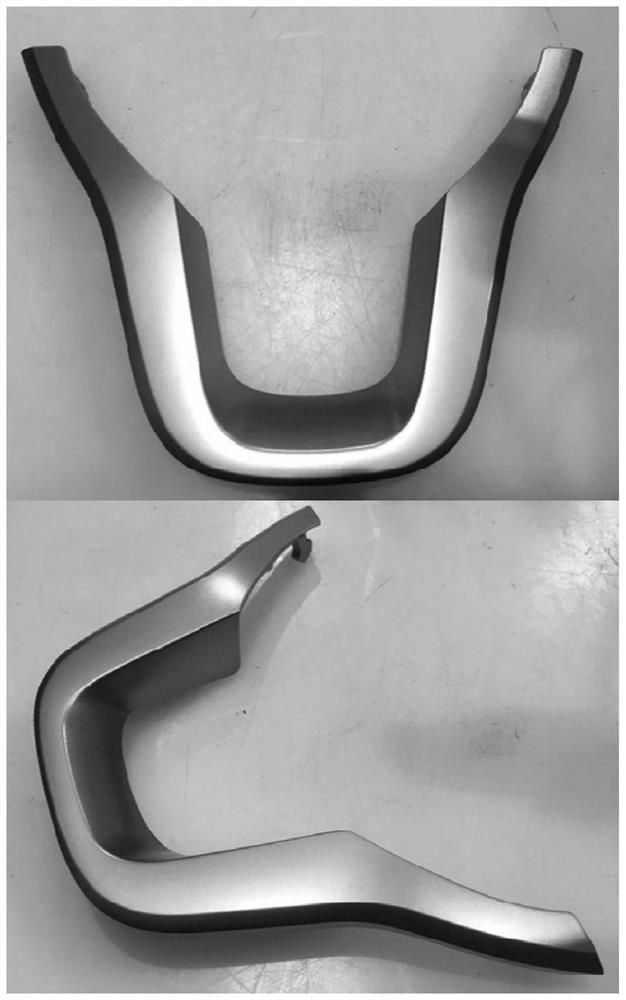

Image

Examples

Embodiment 1

[0030] In the embodiment of the present invention, a rose gold plating process comprising the following steps:

[0031] S1: Treatment of the injection molded plastic workpiece according to the process of sour copper, semicamine nickel, pearl nickel, microporous and photocly chromium, to obtain plating parts, control conditions for each step:

[0032] 1) Acid copper (main reagent is copper sulfate, sulfuric acid): The current density is 5ASD, the plating time is 25 min;

[0033] 2) Semi-light nickel (main reagent is nickel sulfate, nickel chloride, boric acid): The current density is 2ASD, and the electroplating time is 16 min;

[0034] 3) Pearl nickel (main reagent is nickel sulfate, nickel chloride, boric acid): The current density is 4ASD, and the electroplating time is 8 min;

[0035] 4) Micropore nickel (main reagent is nickel sulfate, nickel chloride, boric acid): The current density is 1.5ASD, and the plating time is 2 min;

[0036] 5) Light chrome (main reagent is chromium ...

Embodiment 2

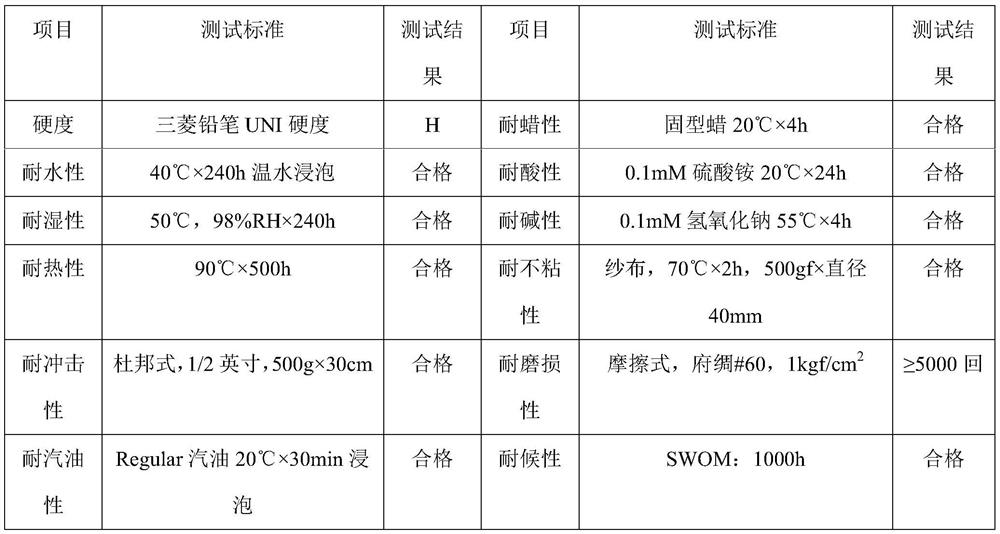

[0062] Workpiece topcoat performance test of rose gold plating spraying process:

[0063] The plastic workpiece obtained by Example 1 was tested, and the results were shown in Table 1.

[0064] Table 1, rose gold face paint performance test results obtained after electroplating

[0065]

[0066] It can be seen from the test results, and the workpiece paint produced by the rose gold plating process of the rose in Example 1 has excellent performance and stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com