A kind of cold-formed steel and its forming process

A forming process and technology of cold-formed steel, which is applied in the field of steel forming, can solve the problems that the surface of steel is prone to damage, reduce the physical and mechanical properties of steel, and affect the quality of surface forming of steel, so as to ensure the effect of coating and improve the quality of forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

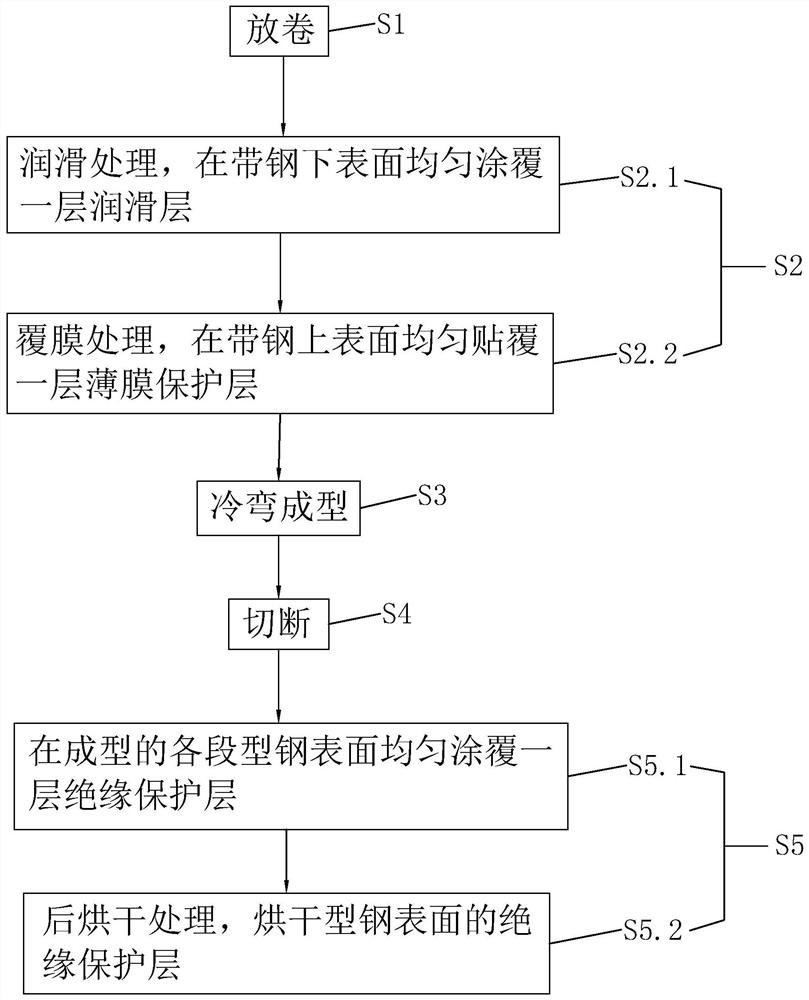

[0043] See attached figure 1 , a cold-formed steel forming process, comprising the following steps:

[0044] S1, unwinding. In the actual production process, the cold-formed section steel can use a section steel forming machine to realize streamlined production operations. The strip steel used in production can be one of ordinary carbon steel, low alloy steel and high strength steel. Before the operation starts, the strip steel is coiled and set on the uncoiler. Unwinding can realize continuous production operation and ensure the efficiency of production operation. After the unwinding of the strip steel is completed, the staff can clean the strip steel online on the assembly line; during operation, the staff can clean the upper and lower surfaces of the strip steel with a cleaning agent to remove foreign matter such as oil stains and debris on the surface of the strip steel; After cleaning, the staff can carry out online drying treatment on the surface of the strip steel on...

Embodiment 2

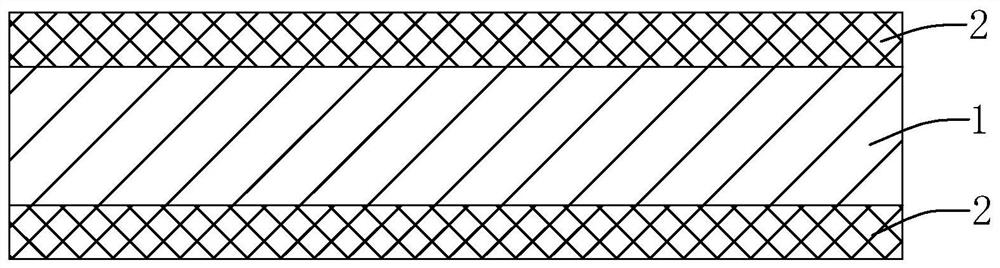

[0057] See attached figure 2 , a kind of cold-formed steel, which is made by the above-mentioned cold-formed steel forming process as a whole, and includes a steel body 1, and the material of the steel body 1 can be one of ordinary carbon steel, low-alloy steel and high-strength steel. The surface of the shaped steel body 1 is evenly coated with an insulating protective layer, which is an epoxy resin insulating layer 2; while ensuring the structural strength of the shaped steel, the epoxy resin insulating layer 2 can meet the user's requirements for the insulating performance of the shaped steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com