Alkali-free glass composition, alkali-free glass and application

A glass composition and alkali-free glass technology, applied in the field of glass, can solve the problems of damage to other properties, unsatisfactory chemical corrosion resistance, etc., and achieve the effects of high mechanical strength, suitable chemical corrosion resistance, and high strain point temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-24 and comparative example 1-3

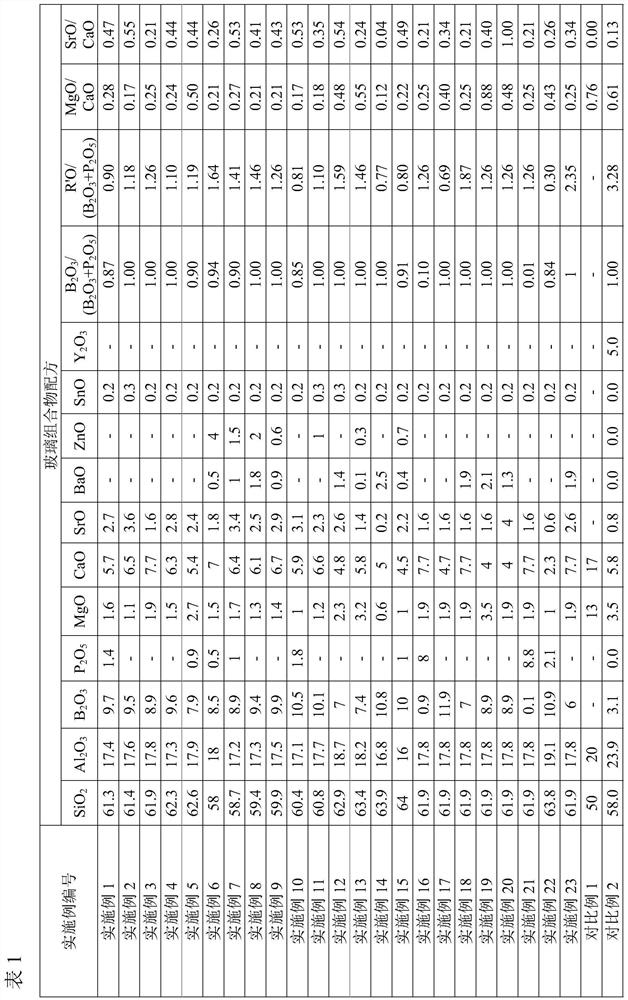

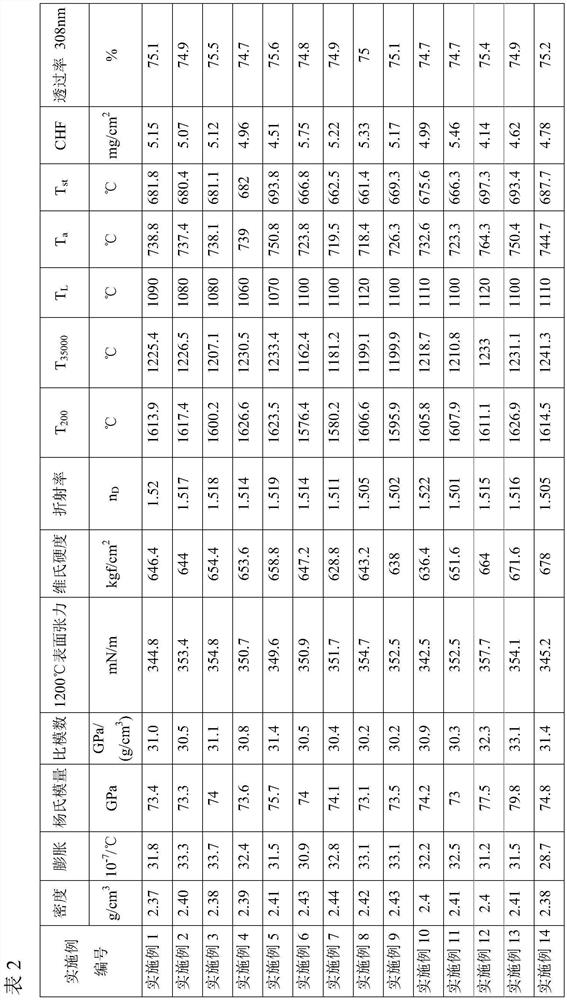

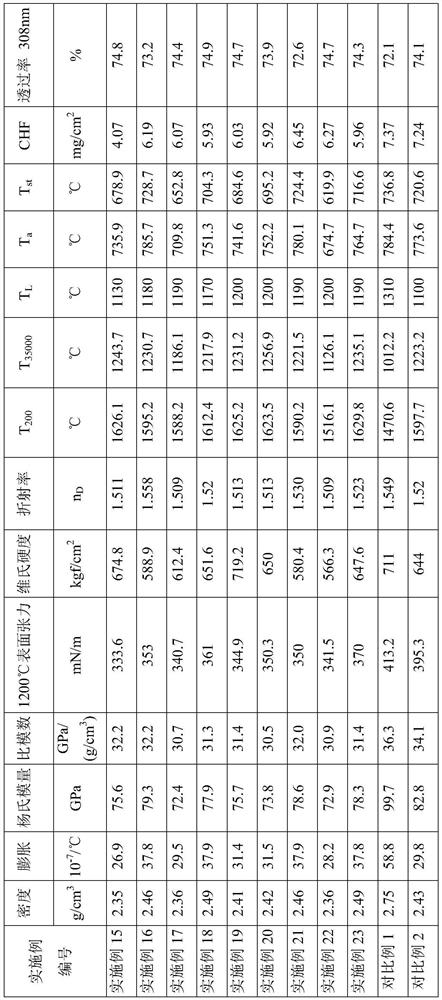

[0119] According to the composition formula of the alkali-free glass composition shown in Table 1, all components were mixed uniformly, and then heated at 1600° C. for 10 hours, and stirred slowly at a uniform speed. The melted glass is poured into the stainless steel cast iron grinding tool to form a specified block glass product, and then the glass product is placed in the annealing furnace at the corresponding annealing point T a Anneal for 2 hours, turn off the power and cool down to 25°C with the furnace. The glass product is cut, ground and polished, then cleaned with deionized water and dried to obtain a finished glass product with a thickness of 0.5mm. Various properties of each glass product were measured respectively, and the results are shown in Table 2.

[0120]

[0121] "-" in Table 1 means that this component is not contained or this parameter does not exist.

[0122]

[0123]

[0124]

[0125]

[0126]

[0127]

[0128]

[0129] As can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com