Continuous preparation method of photoinitiator

A photoinitiator and pipeline reactor technology, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of low production efficiency and quality differences between different batches, and achieve high production efficiency and high product quality. The effect of stability and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

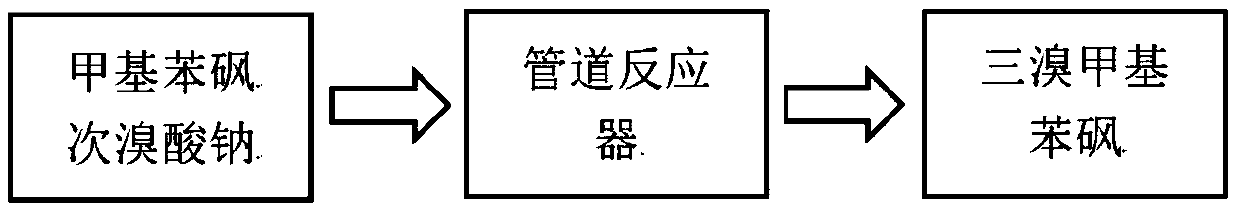

[0027] The invention provides a continuous preparation method of a photoinitiator, wherein, in a pipeline reaction system, preferably in a pipeline reactor, methyl phenyl sulfone and sodium hypobromite solution react according to the following reaction formula to obtain three Bromomethylphenylsulfone,

[0028]

[0029] The sodium hypobromite solution is prepared from bromine, liquid caustic soda and sodium hypochlorite solution.

[0030] In the prior art in the past, sodium hypobromite solution is prepared by bromine and liquid caustic soda, and reaction formula is as follows:

[0031]

[0032] However, with this preparation method, the utilization rate of bromine is only 50%, and bromine usually exists in the form of sodium bromide in the aqueous solution and has no reactivity. And the present invention is by continuing to add sodium hypochlorite solution in the sodium hypobromite solution (containing sodium bromide) after bromine and liquid alkali reaction, sodium bro...

Embodiment 1

[0048] Sodium hypobromite solution preparation:

[0049] Add 56.7g of bromine dropwise into 193g of 15%w liquid caustic soda at 0-5°C, stir for half an hour, then add 225g of sodium hypochlorite solution into the reaction solution, stir for half an hour to obtain sodium hypobromite solution for later use. In other embodiments, the sodium hypobromite solution is formulated and used according to this ratio.

[0050] Preparation of reaction solution:

[0051] In a 20L reactor at 20°C, add 674g of methyl phenyl sulfone, 1.5kg of 30%w liquid caustic soda, 3.4g of catalyst, and 9.5kg of sodium hypobromite solution in sequence, stir for half an hour until the feed liquid is uniform, and keep Stir and set aside. (Methyl phenyl sulfone to sodium hypobromite molar ratio=1:3)

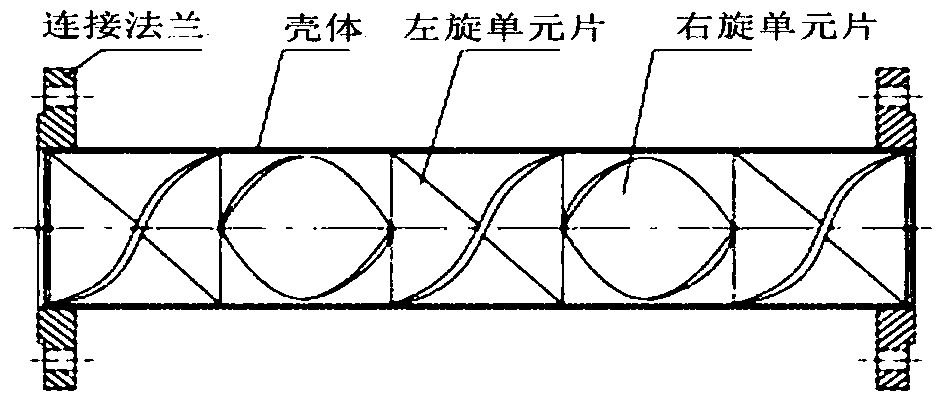

[0052] The reaction raw materials are fed into the pipeline reactor in the form of slurry, and the mass concentration of methylphenyl sulfone is 6%w. The reaction slurry volume flow rate is 10L / h. Pipeline re...

Embodiment 2

[0054] In a 20L reactor at 20°C, sequentially add 674g of methyl phenyl sulfone, 1.5kg of 30%w liquid caustic soda, 3.4g of catalyst, and 9.5kg of sodium hypobromite solution, and stir for half an hour until the feed liquid is uniform, then keep stirring spare. (Methyl phenyl sulfone to sodium hypobromite molar ratio=1:3)

[0055] The reaction raw materials are fed into the pipeline reactor in the form of slurry, and the mass concentration of methylphenyl sulfone is 6%w. The reaction slurry volume flow rate is 15 L / h. Pipeline reactors 1 to 5 are reaction modules, the temperature is controlled at 100°C, the reaction is carried out under normal pressure, and the residence time is 2.4 minutes. Pipeline reactor 6 is a cooling module, and the temperature is controlled at 25°C. After post-processing and liquid chromatography analysis, the content of the finished product is 99.8% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com