Dyeing method for single-sided towel and quilt fabric

A dyeing method and quilt technology, applied in the field of textile dyeing and finishing, to achieve the effects of stable dyeing medium, balanced pH value and uniform permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

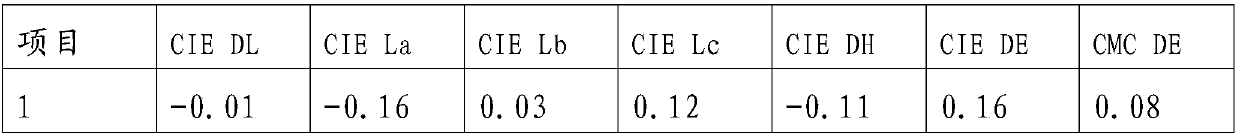

Embodiment 1

[0032] (1) Continuous open-width pretreatment: first add 600L water to the rolling liquid tank, then add 10g / L tea saponin, 2g / L emulsifier DF-60R, 30ml / L hydrogen peroxide (H 2 o 2 content is 27.5wt%), finally made into 1000L of compound cooking liquid.

[0033] The single-faced towel fabric is subjected to continuous open-width pretreatment, and is impregnated with the compound simmering liquid in the rolling tank; the amount of liquid carried by the single-faced towel fabric is 110%, and the uniform pressure of the padding machine is set to 0.25Mpa; at 98°C Steamed for 45 minutes in a composite steamer, and then washed in open width to make gray cloth to be dyed.

[0034] The waste water produced by soaking and pressing in the continuous open-width pretreatment process is filtered by a filter device to remove cellulose cotton wool, and then the reused water is obtained through precipitation. The pH value of the reused water is 8.6, and the water hardness is: 3mg / L, meetin...

Embodiment 2

[0038] (1) Continuous open-width pre-treatment: first add 600L water to the liquid rolling tank, then add 9g / L tea saponin, 2.5g / L emulsifier DF-60R, 28ml / L hydrogen peroxide (H 2 o 2 content is 27.2wt%), and finally made into 1000L of compound cooking liquor.

[0039] The single-faced towel fabric is subjected to continuous open-width pretreatment, and is impregnated with the compound simmering liquid in the rolling tank; the liquid-carrying amount of the single-faced towel fabric is 105%, and the uniform pressure of the padding machine is set to 0.20Mpa; at 96°C Steamed for 50 minutes in a composite steamer, and then washed in open width to make gray fabric to be dyed.

[0040] The waste water produced by soaking and pressing in the continuous open-width pretreatment process is filtered through a filter device to remove cellulose cotton wool, and then the reused water is obtained through precipitation. The pH value of the reused water is 8.8, and the water hardness is: 4mg...

Embodiment 3

[0044] (1) Continuous open-width pretreatment: first add 600L water to the rolling liquid tank, then add 12g / L tea saponin, 3g / L emulsifier DF-60R, 35ml / L hydrogen peroxide (H 2 o 2 content is 27.5wt%), finally made into 1000L of compound cooking liquid.

[0045] The single-face towel fabric is subjected to continuous open-width pre-treatment, and is impregnated with the compound cooking liquid in the rolling tank; the liquid-carrying amount of the single-face towel fabric is 120%, and the uniform pressure of the padding machine is set to 0.30Mpa; at 100°C Steamed for 40 minutes in a composite steamer, and then washed in open width to make gray cloth to be dyed.

[0046] The waste water produced by soaking and pressing in the continuous open-width pretreatment process is filtered through a filter device to remove cellulose cotton wool, and then the reused water is obtained through precipitation. The index of the reused water is pH value: 9, and the water hardness is: 5mg / L, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water hardness | aaaaa | aaaaa |

| Water hardness | aaaaa | aaaaa |

| Water hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com