Mixing arrangement

A technology of mixing device and mixing section, applied in mixers, electric heating devices, mufflers, etc., can solve the problems of non-decomposition, inability to efficiently provide selective catalytic reduction, and ineffective mixing of reactants with exhaust gas, etc. Improve the effect of heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

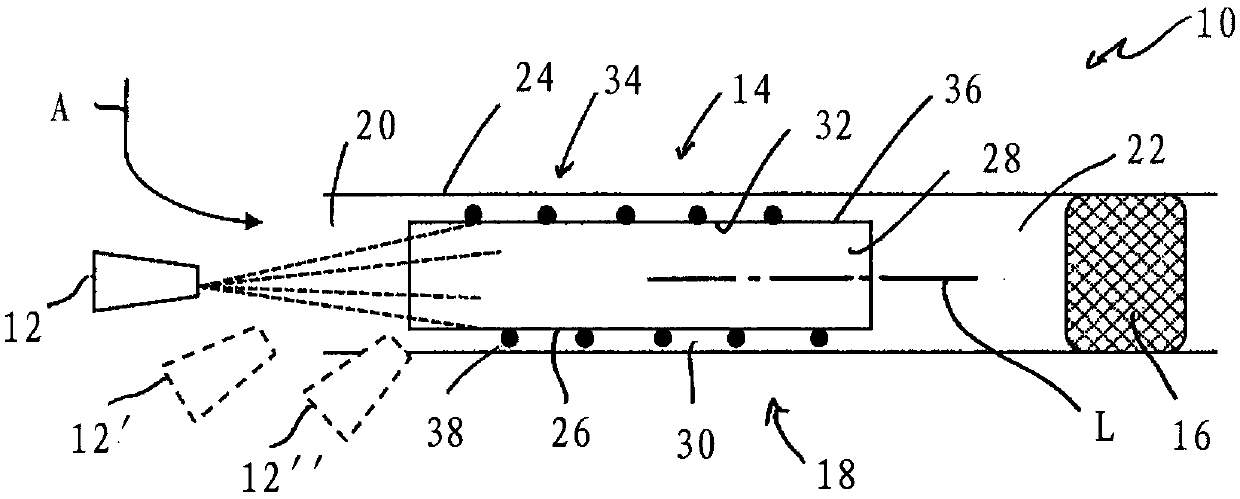

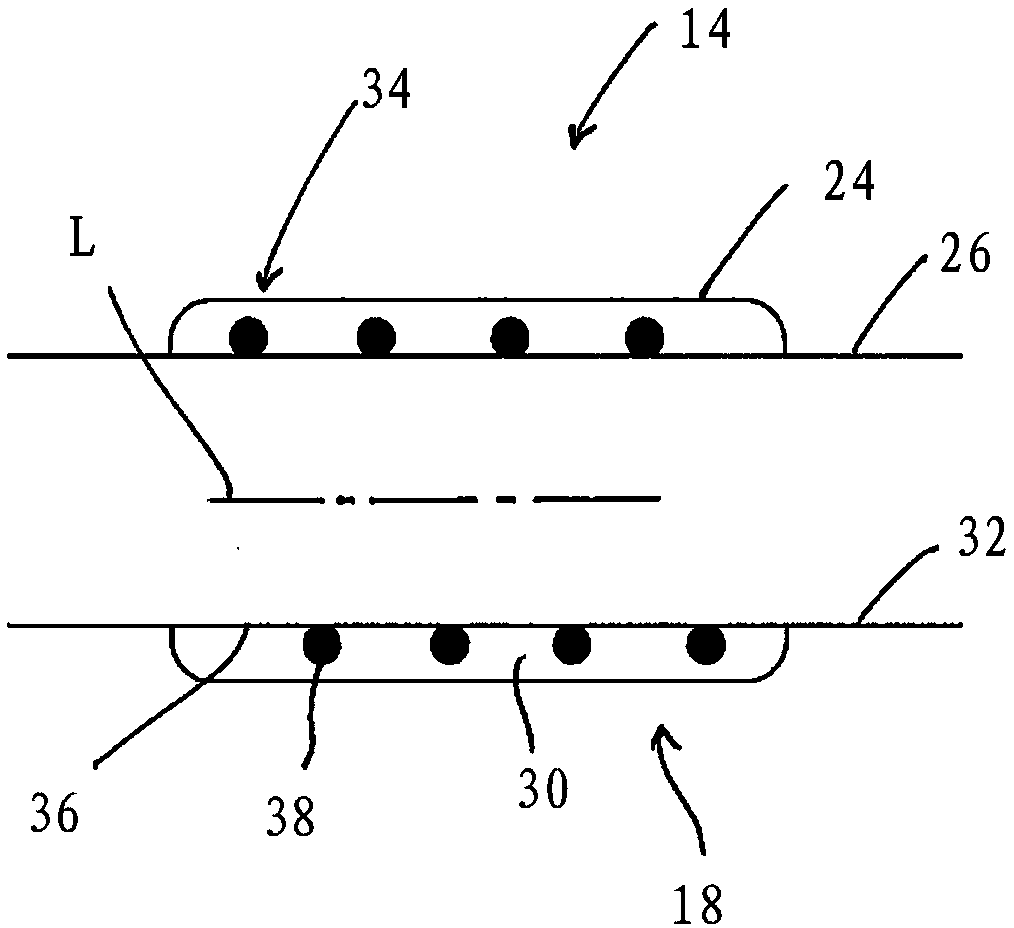

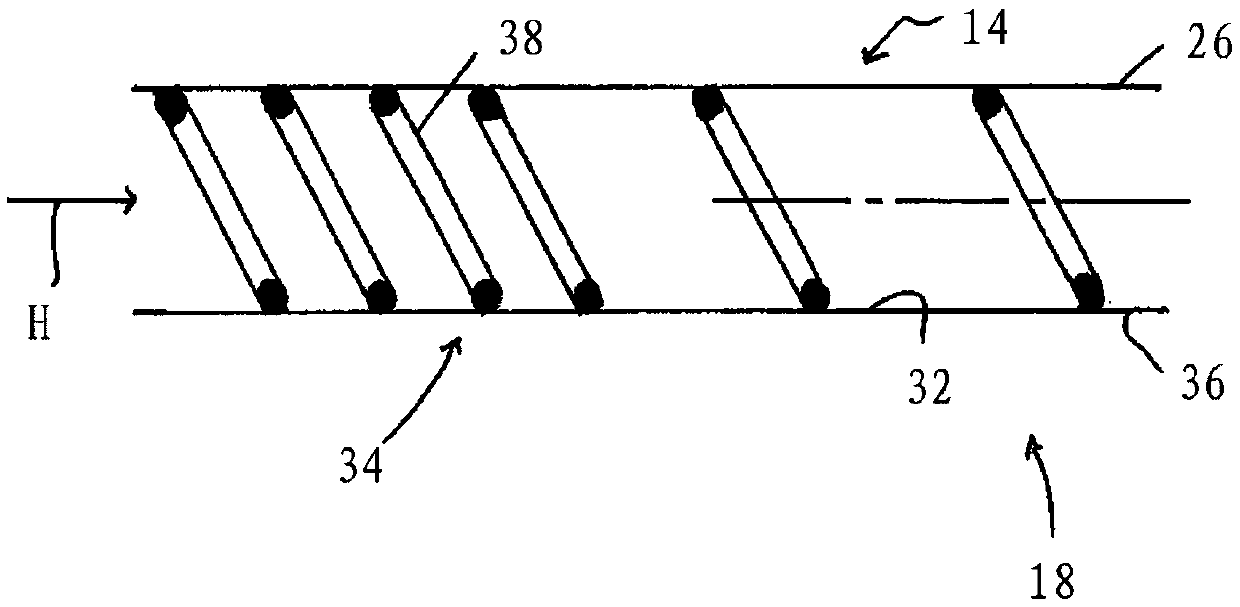

[0039] figure 1 For example, a part of the exhaust system of an internal combustion engine in a vehicle, denoted in its entirety by the reference numeral 10 , is shown in a schematic diagram. The exhaust system 10 includes a reactant outlet 12 , via which a reactant, such as urea / water solution, is added to the exhaust gas A flowing further upstream. Downstream of the reactant discharge device 12 (which is usually also referred to as an injector), there is a mixing device 14 in which the reactant R is mixed with the exhaust gas A. FIG. In this case, the water contained in the reactants R is vaporized and the urea is thermally decomposed, thereby producing ammonia and generally also isocyanic acid, which can be converted further into ammonia in a catalytic reaction with the vaporized water in a pyrolysis reaction. The ammonia produced by the reactants is catalytically converted in the downstream SCR catalyst device 16 in order to reduce the proportion of harmful nitrogen oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com