Double-ring-type windshield ring cooling system integration

A technology of cooling system and wind protection ring, which is applied in the direction of engine cooling, engine components, machine/engine, etc., can solve the problems of insufficient use of assembly space, single assembly method of wind protection ring, and reduce the efficiency of cooling fans, etc., to achieve structural Simplicity, low cost, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

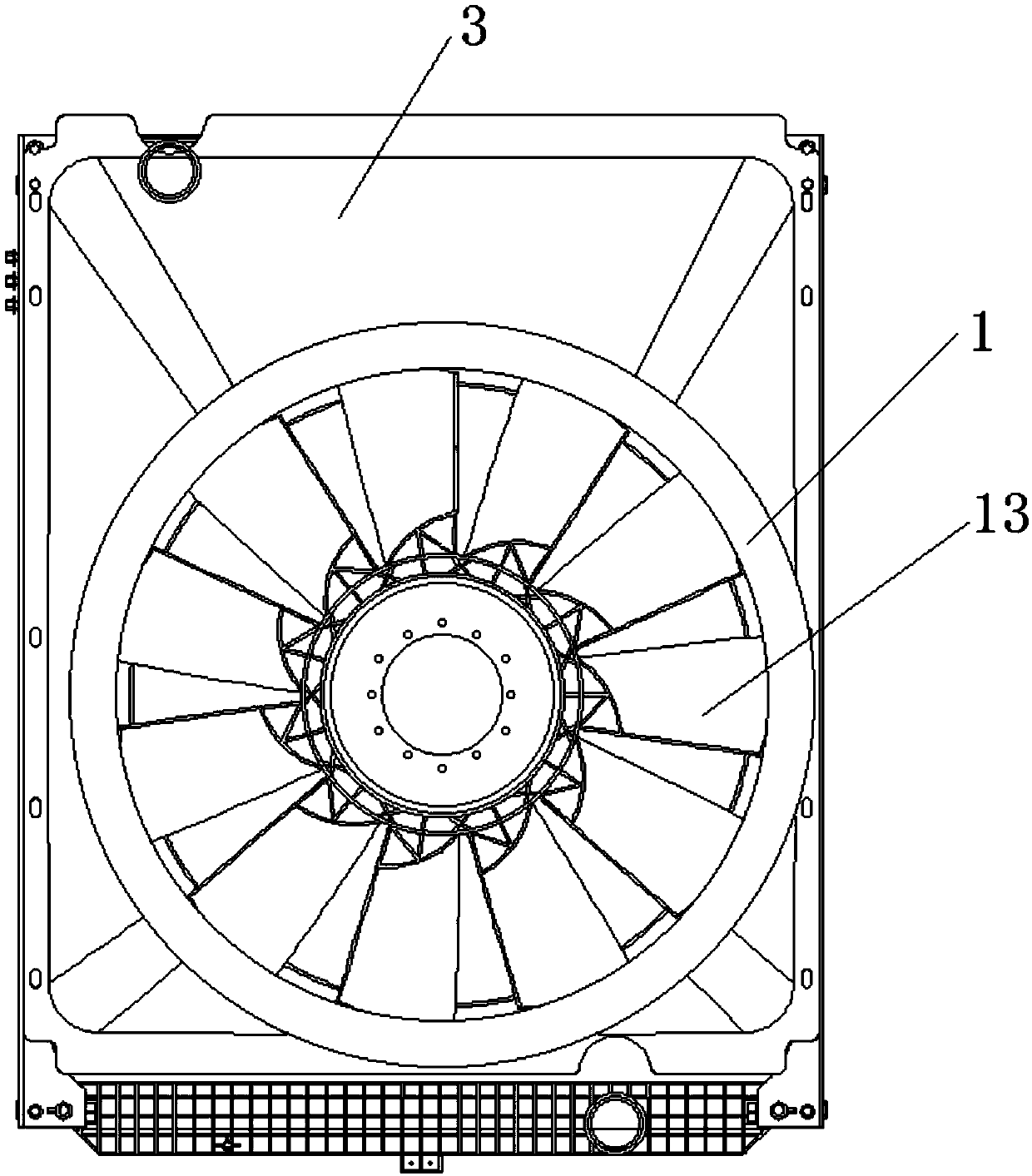

[0026] The wind protection ring 2 and the radiator 3 are installed on the girder of the automobile, and the fan 1 is set on the engine. The return air duct 4 is obtained by embedded installation.

[0027] Such as image 3 , Figure 4 , Figure 5 As shown, the return air duct 4 is obtained by embedding the outer ring 11 of the fan and the inner ring 12 of the fan ring into the outer ring 21 of the wind protection ring and the inner ring 22 of the wind protection ring respectively or through the outer ring 21 of the wind protection ring and the inner ring 22 of the wind protection ring 22 respectively. It is obtained by being embedded in the fan outer ring 11 and the fan inner ring 12, therefore, the fan 1 and the wind guard ring 2 can be installed in a staggered manner.

[0028] The fan 1 and the wind protection ring 2 are installed in a staggered manner, the gap between the fan outer ring 11 and the wind protection ring outer ring 21 is 3 mm, the distance between the wind p...

Embodiment 2

[0031] The wind protection ring 2 and the radiator 3 are installed on the girder of the automobile, and the fan 1 is set on the engine. The return air duct 4 is obtained by embedded installation.

[0032] Such as image 3 , Figure 4 , Figure 5 As shown, the return air duct 4 is obtained by embedding the outer ring 11 of the fan and the inner ring 12 of the fan ring into the outer ring 21 of the wind protection ring and the inner ring 22 of the wind protection ring respectively or through the outer ring 21 of the wind protection ring and the inner ring 22 of the wind protection ring 22 respectively. It is obtained by being embedded in the fan outer ring 11 and the fan inner ring 12, therefore, the fan 1 and the wind guard ring 2 can be installed in a staggered manner.

[0033] The fan 1 and the wind protection ring 2 are installed in a staggered manner, the gap between the fan outer ring 11 and the wind protection ring outer ring 21 is 28mm, the distance between the wind p...

Embodiment 3

[0036] The wind protection ring 2 and the radiator 3 are installed on the girder of the automobile, and the fan 1 is set on the engine. The return air duct 4 is obtained by embedded installation.

[0037] Such as image 3 , Figure 4 , Figure 5 As shown, the return air duct 4 is obtained by embedding the outer ring 11 of the fan and the inner ring 12 of the fan ring into the outer ring 21 of the wind protection ring and the inner ring 22 of the wind protection ring respectively or through the outer ring 21 of the wind protection ring and the inner ring 22 of the wind protection ring 22 respectively. It is obtained by being embedded in the fan outer ring 11 and the fan inner ring 12, therefore, the fan 1 and the wind guard ring 2 can be installed in a staggered manner.

[0038] The fan 1 and the wind protection ring 2 are installed in a staggered manner, the gap between the fan outer ring 11 and the wind protection ring outer ring 21 is 30 mm, the distance between the wind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com