Method for operating filtering device

A filter device and operation method technology, applied in the direction of filter separation, separation method, filter circuit, etc., can solve the problems that the filter equipment cannot complete the filter task, is toxic and harmful, and has complex components, and achieves the effect of improving the rapid removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

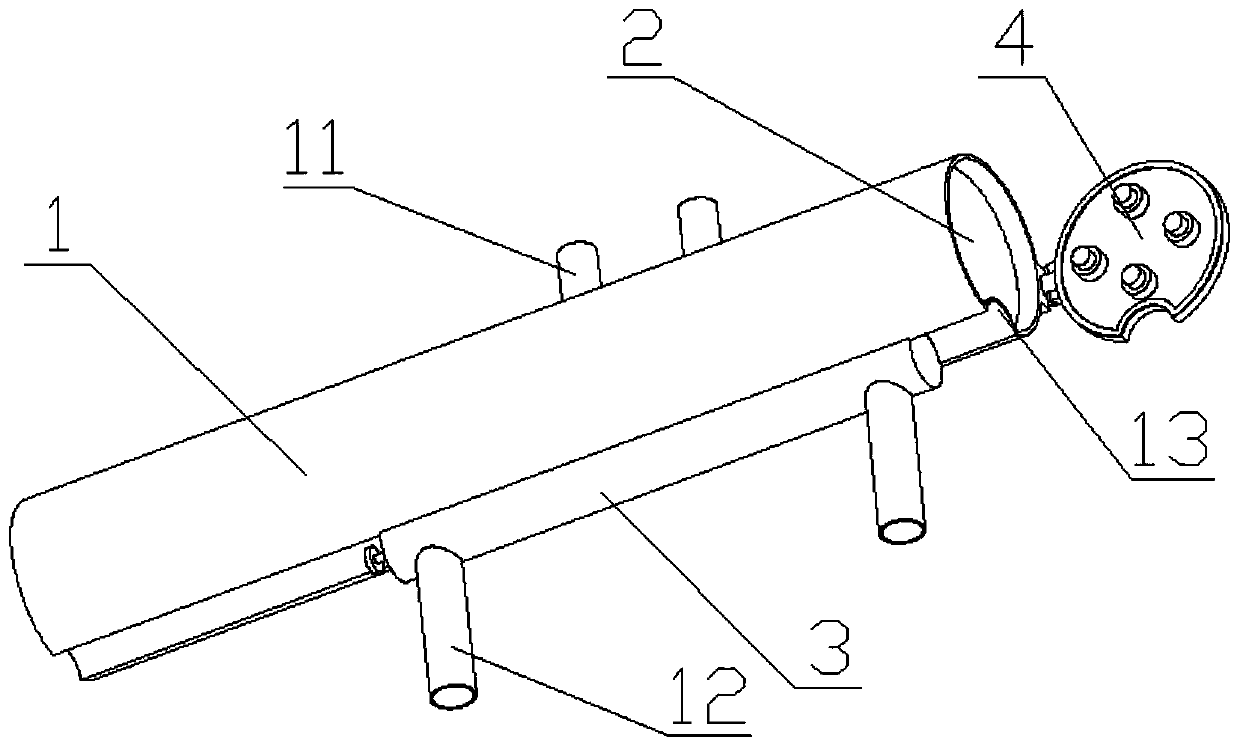

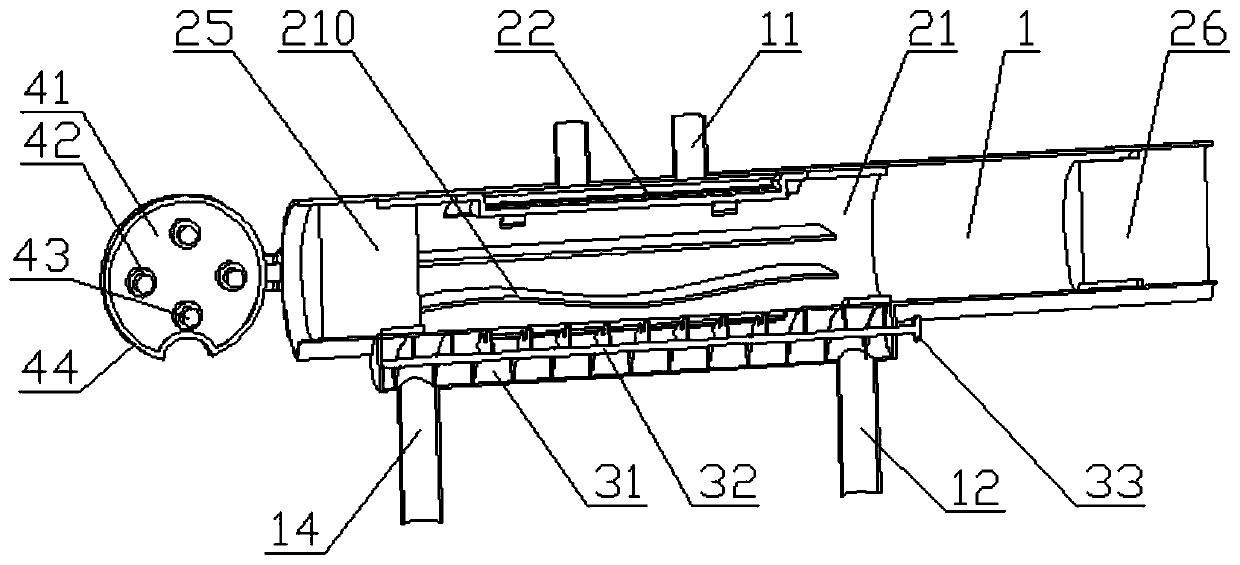

[0039] like Figure 1 to Figure 6Shown; A kind of operation method of filter device, comprises filter pipe 1, filter mechanism 2 and controller, described filter mechanism 2 is arranged in the filter pipe 1, and described filter pipe 1 end is provided with pressure measurement sealing mechanism 4, The other end of the filter tube 1 is provided with an oil cylinder, and the power end of the oil cylinder presses the filter mechanism 2 on the working side of the pressure measuring and sealing mechanism 4; One side of the filter pipe 1 of the liquid pipe 11 is provided with an anti-blocking sewage discharge mechanism 3, the liquid inlet pipe 12 is connected to the anti-blockage sewage discharge mechanism 3, a vacuum water tank is connected to the liquid discharge pipe 11, and a vacuum water tank is arranged on the vacuum water tank. There are vacuum pumps, drains and pressure gauges, the anti-blocking and sewage discharge mechanism 3 communicates with the filter pipe 1 and coopera...

Embodiment 2

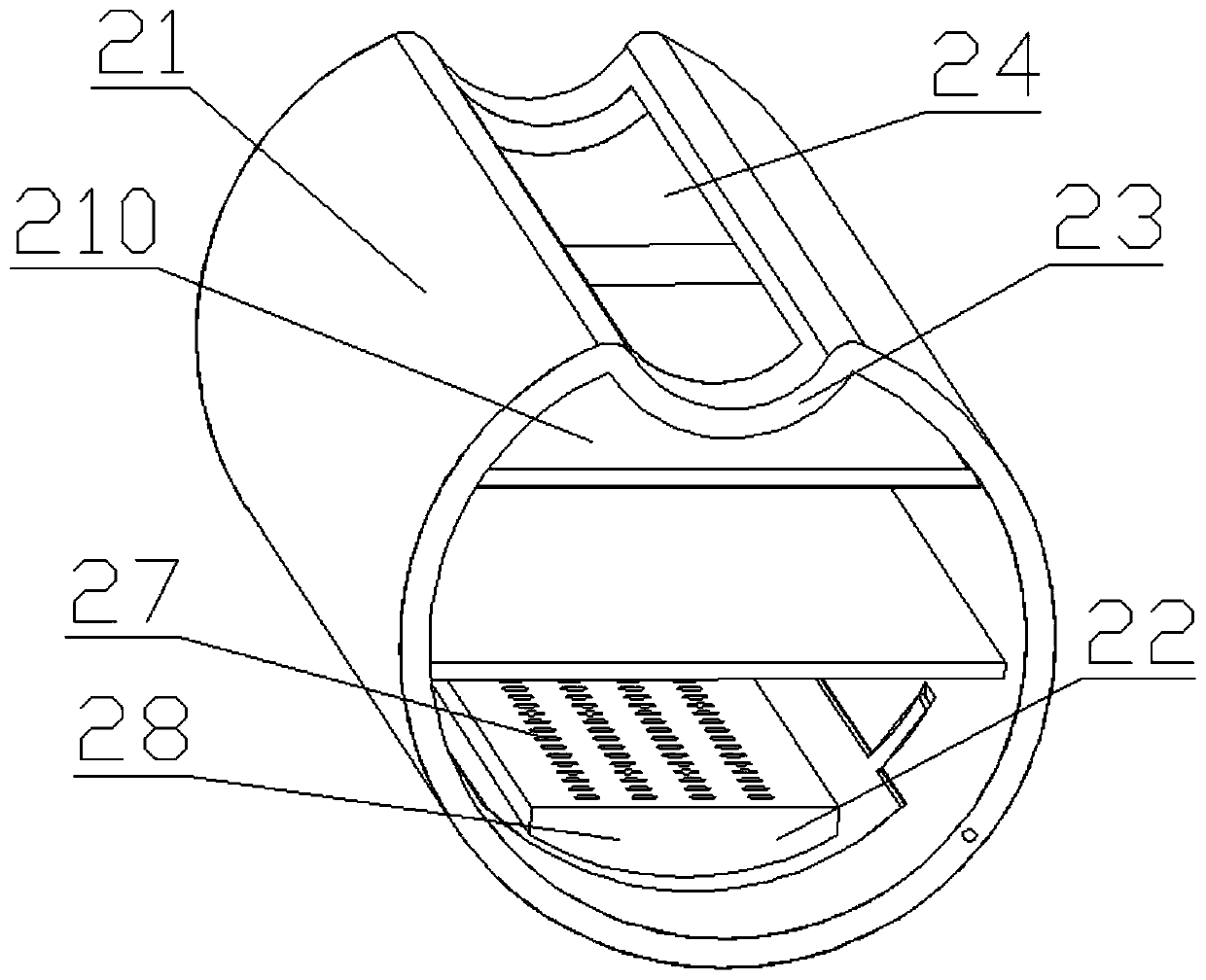

[0056] On the basis of Embodiment 1, the pressure measuring and sealing mechanism 4 includes a sealing door 41, and at least one pressure sensor 42 is arranged on the sealing door 41, and a buffer block 43 is arranged on the pressure sensor 42. The sealing door 41 is provided with a sealing gasket 44; the pressure sensor 42 is electrically connected to the controller; one side of the filter barrel 21 is provided with a filtered liquid door 22, and the filtered liquid door 22 is provided with a concave return cavity 27, the liquid outlet hole 28 is set on the concave return cavity 27; the filter barrel 21 is provided with an inner arc-shaped sliding wall 23 on one side, the transition hole 24 is set in the inner arc-shaped sliding wall 23, and the filter One side of the tube 1 is provided with an outer arc-shaped sliding wall 13 that cooperates with the inner arc-shaped sliding wall 23; the filter bucket 21 is provided with at least two sealing strips, and the sealing strips are...

Embodiment 3

[0059] On the basis of Example 2, the gap between the filter tube 1 and the filter bucket 21 is 0.5mm to 2.0mm, and the thickness of the sealing ring 29 is 10mm to 20mm; the sealing ring 29 is made of silica gel, and the silica gel The hardness is 20 degrees to 50 degrees; the screw 32 revolving blade located on one side of the transition hole 24 is provided with a slow pressure cleaning notch 34; the ratio of the width of the screw 32 revolving blade to the width of the slow pressure cleaning notch 34 1:0.3~0.7.

[0060]By setting the gap between the filter tube 1 and the filter bucket 21 to 0.5mm to 2.0mm, the phenomenon of difficulty in installation can be avoided. If the gap is too large, the filter will also flow directly to the liquid outlet pipe 11; It is set to 10mm to 20mm, and the hardness is set to 20 degrees to 50 degrees, so that after the sealing ring 29 is under pressure, one side thereof will be squeezed and deformed so that the side surface contacts the inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com