Multi-layer graphite heat conducting plate and preparation method thereof

A technology of graphite heat conduction and graphite flakes, applied in chemical instruments and methods, modification and lamination through conduction and heat transfer, etc., can solve problems such as heavy weight of copper tubes, difficulty in forming special-shaped tubes, heavy weight of electronic products, etc., and achieve high The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

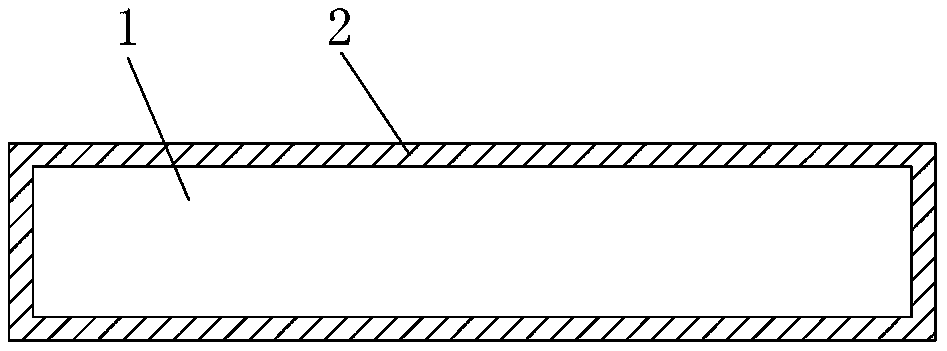

[0021] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] The invention discloses a preparation method of a multilayer graphite heat conducting plate, comprising the following steps:

[0023] According to the set thickness, select a number of high thermal conductivity graphite sheets, and use thin surface glue to paste each high thermal conductivity graphite sheet together to form a graphite heat conduction plate. There is no limit to the specific number of graphite sheets, and the corresponding number is selected according to the required overall thickness. The graphite flakes can be natural graphite flakes, synthetic graphite flakes or graphene flakes.

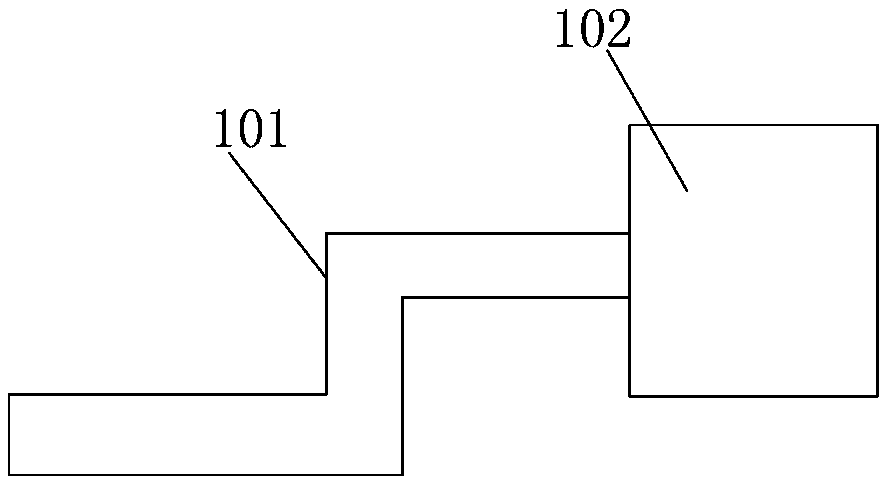

[0024] Cut the graphite heat conduction plate into a set shape, which can be regular or irregula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com