Alloy graphite steel roll for seamless steel tube continuous rolling machine and preparation method thereof

A technology of seamless steel pipe and graphite steel, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of easy failure of rolls, improve brightness, improve crack resistance and wear resistance, and ensure uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

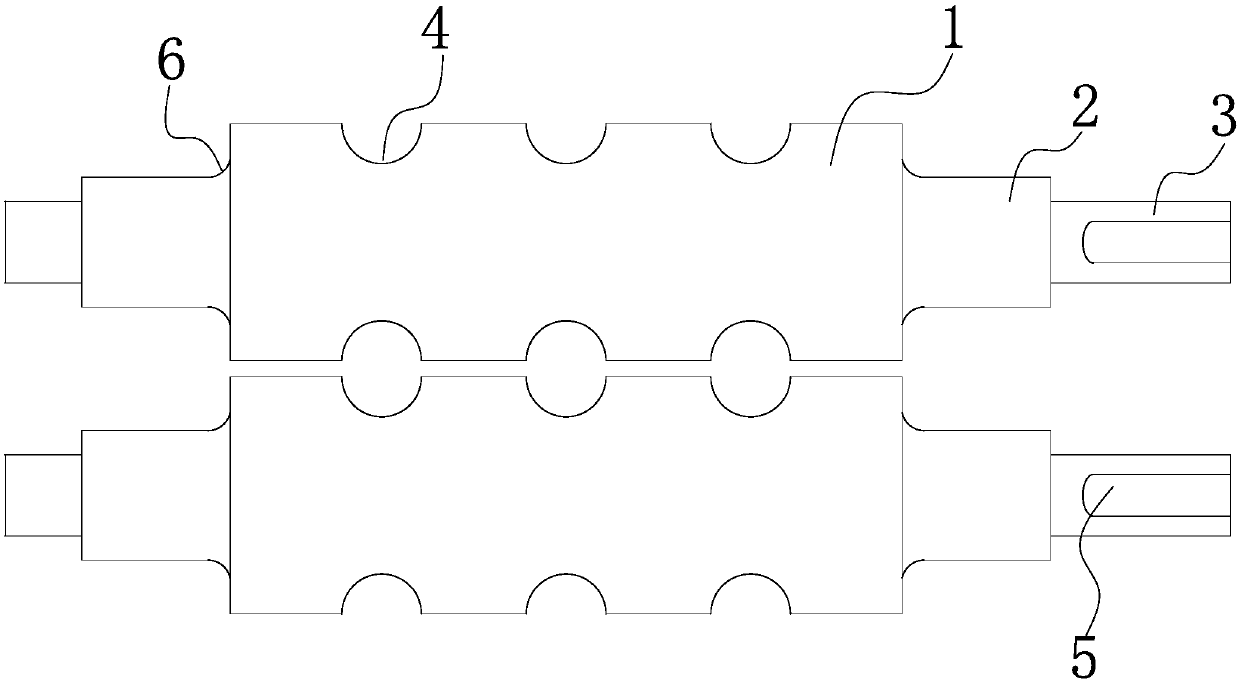

Image

Examples

Embodiment 1

[0031] The chemical composition of an alloy graphite steel roll for a seamless steel pipe continuous rolling mill is:

[0032] C: 1.60%; Si: 1.60%; Mn: 1.20%; Cr: 1.50%; Ni: 2.00%; Mo: 0.40%; V: 0.40%; Nb: 0.20%; P: 0.03%; S: 0.015%; Re: 10%; the remainder is Fe and unavoidable impurities.

[0033] The matrix metallographic structure of alloy graphite steel rolls for continuous rolling mills of seamless steel pipes is Cr 23 C 6 、Mo 2 C 6 , NbC, V 4 C 3 Granular carbide + tempered sorbite + bainite.

[0034] A preparation method of an alloy graphite steel roll for a seamless steel pipe continuous rolling mill, comprising the following steps:

[0035] (1) Configuration chemical composition: C: 1.60%; Si: 1.60%; Mn: 1.20%; Cr: 1.50%; Ni: 2.00%; Mo: 0.40%; V: 0.40%; Nb: 0.20%; P: 0.03 %; S: 0.015%; Re: 10%; the rest is Fe and unavoidable impurities;

[0036] (2) Smelting: Add the configured chemical components into the electric melting furnace for smelting, and when the t...

Embodiment 2

[0040] The chemical composition of an alloy graphite steel roll for a seamless steel pipe continuous rolling mill is:

[0041] C: 1.80%; Si: 0.80%; Mn: 0.60%; Cr: 1.50%; Ni: 1.00%; Mo: 0.80%; V: 0.20%; Nb: 0.40%; P: 0.025%; S: 0.025%; Re: 0.05%; the remainder is Fe and unavoidable impurities.

[0042] The matrix metallographic structure of alloy graphite steel rolls for continuous rolling mills of seamless steel pipes is Cr 23 C 6 、Mo 2 C 6 , NbC, V 4 C 3 Granular carbide + tempered sorbite + bainite.

[0043] A preparation method of an alloy graphite steel roll for a seamless steel pipe continuous rolling mill, comprising the following steps:

[0044] (1) Configuration chemical composition: C: 1.80%; Si: 0.80%; Mn: 0.60%; Cr: 1.50%; Ni: 1.00%; Mo: 0.80%; V: 0.20%; Nb: 0.40%; %; S: 0.025%; Re: 0.05%; the rest is Fe and unavoidable impurities;

[0045] (2) Smelting: Add the configured chemical components into the electric melting furnace for smelting, and when the temp...

Embodiment 3

[0049] The chemical composition of an alloy graphite steel roll for a seamless steel pipe continuous rolling mill is:

[0050] C: 1.70%; Si: 1.20%; Mn: 1.00%; Cr: 1.15%; Ni: 1.50%; Mo: 0.60%; V: 0.30%; Nb: 0.30%; P: 0.025%; S: 0.020%; Re: 0.075%; the remainder is Fe and unavoidable impurities.

[0051] The matrix metallographic structure of alloy graphite steel rolls for continuous rolling mills of seamless steel pipes is Cr 23 C 6 、Mo 2 C 6 , NbC, V 4 C 3 Granular carbide + tempered sorbite + bainite.

[0052] A preparation method of an alloy graphite steel roll for a seamless steel pipe continuous rolling mill, comprising the following steps:

[0053] (1) Configuration chemical composition: C: 1.70%; Si: 1.20%; Mn: 1.00%; Cr: 1.15%; Ni: 1.50%; Mo: 0.60%; V: 0.30%; Nb: 0.30%; P: 0.025 %; S: 0.020%; Re: 0.075%; the rest is Fe and unavoidable impurities;

[0054] (2) Smelting: Add the configured chemical components into the electric melting furnace for smelting, and wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com