Heat treatment process for improving mechanical property of Fe-Mn-Al-C dual-phase steel by utilizing gamma-to-alpha allotropy transformation

A fe-mn-al-c, allotrope technology, applied in the heat treatment process for improving the mechanical properties of low-density and high-strength cold-rolled steel sheets, low-density and high-strength cold-rolled steel and its heat treatment process, high-aluminum lightweight steel In the field of its heat treatment process, it can solve the problems of restricting the addition of aluminum elements, reducing the mechanical properties of steel plates, and difficult to produce TRIP or TWIP effects, and achieve the effects of optimizing quality, increasing solid solution, and improving the coordination of two-phase deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, a kind of Fe-Mn-Al-C dual-phase steel, its composition by mass percentage is: C: 0.80%, Mn: 15.0%, Al: 8.50%, Si: 1.50%, balance is Fe Elements and unavoidable impurity elements, Fe-Mn-Al-C dual-phase steel is austenite and ferrite structure. The Fe-Mn-Al-C dual phase steel in this embodiment is an austenite matrix dual phase steel.

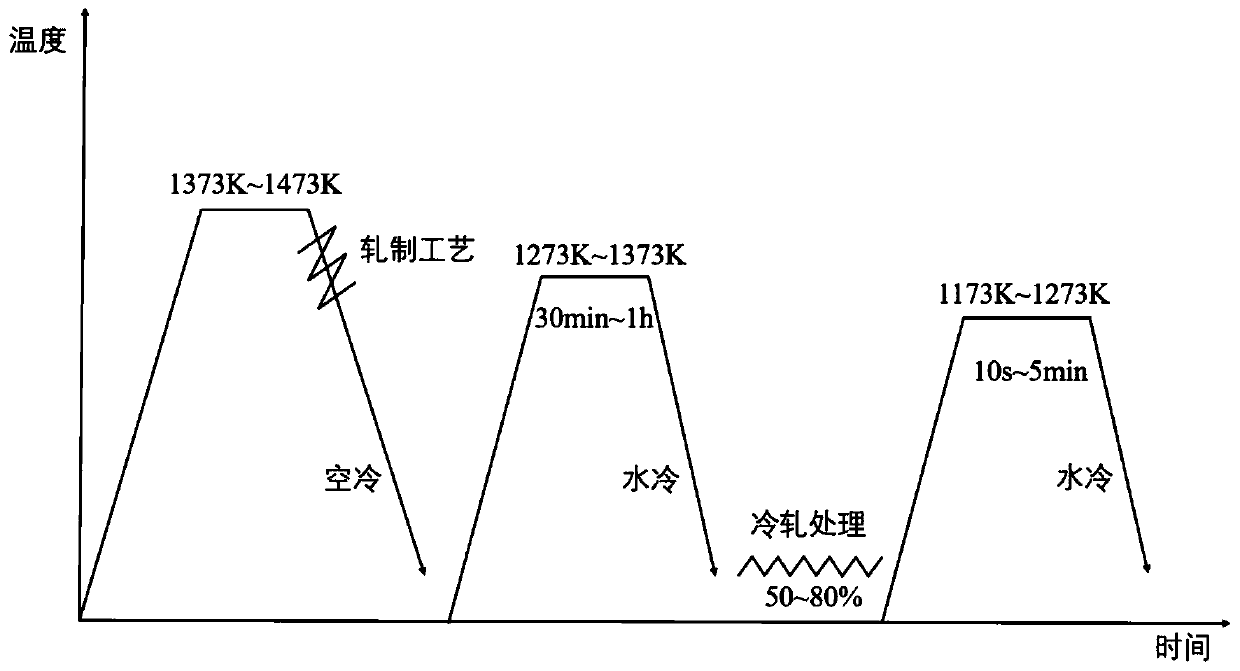

[0042] In this example, see figure 1 , a heat treatment process that uses γ→α isotropic transformation to improve the mechanical properties of Fe-Mn-Al-C dual-phase steel, so that γ→α isotropic transformation occurs at the austenite grain boundary of Fe-Mn-Al-C steel Prime isomerization transformation, prepares Fe-Mn-Al-C dual-phase steel, comprises the steps:

[0043] a. Hot rolling Fe-Mn-Al-C steel, wherein the composition of Fe-Mn-Al-C steel is: C: 0.80%, Mn: 15.0%, Al: 8.50%, Si: 1.50% , the balance is Fe element and unavoidable impurity elements; use vacuum induction smelting furnace to smelt to obtain 82mm ingo...

Embodiment 2

[0051] This embodiment is basically the same as Embodiment 1, especially in that:

[0052] In this embodiment, a kind of Fe-Mn-Al-C dual-phase steel, its composition by mass percentage is: C: 0.30%, Mn: 15.00%, Al: 10.00%, the balance is Fe element and unavoidable Impurity elements, Fe-Mn-Al-C dual-phase steel is austenite and ferrite structure. The Fe-Mn-Al-C dual phase steel in this embodiment is a ferrite matrix dual phase steel.

[0053] In this example, see figure 1 , a heat treatment process that uses γ→α isotropic transformation to improve the mechanical properties of Fe-Mn-Al-C dual-phase steel, so that γ→α isotropic transformation occurs at the austenite grain boundary of Fe-Mn-Al-C steel Prime isomerization transformation, prepares Fe-Mn-Al-C dual-phase steel, comprises the steps:

[0054] a. The Fe-Mn-Al-C steel is hot-rolled, wherein the composition of the Fe-Mn-Al-C steel is: C: 0.30%, Mn: 15.00%, Al: 10.00%, and the balance is Fe Elements and unavoidable impu...

Embodiment 3

[0062] This embodiment is basically the same as the previous embodiment, and the special features are:

[0063] In this embodiment, a kind of Fe-Mn-Al-C dual-phase steel, its composition by mass percentage is: C: 0.8%, Mn: 15.0%, Al: 7.00%, Si: 3.00%, balance is Fe Elements and unavoidable impurity elements, Fe-Mn-Al-C dual-phase steel is austenite and ferrite structure. The Fe-Mn-Al-C dual phase steel in this embodiment is an austenite matrix dual phase steel.

[0064] In this example, see figure 1 , a heat treatment process that uses γ→α isotropic transformation to improve the mechanical properties of Fe-Mn-Al-C dual-phase steel, so that γ→α isotropic transformation occurs at the austenite grain boundary of Fe-Mn-Al-C steel Prime isomerization transformation, prepares Fe-Mn-Al-C dual-phase steel, comprises the steps:

[0065]a. Hot rolling the Fe-Mn-Al-C steel, wherein the composition of the Fe-Mn-Al-C steel is: C: 0.80%, Mn: 15.00%, Al: 7.00%, Si: 3.00% , the balance is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com