Preparation method of natural ecological N-type structural cotton

An N-type, ecological technology, applied in the direction of enzyme/microbial biochemical treatment, biochemical fiber treatment, non-woven fabrics, etc., can solve the problems of easy deformation, health hazards, growth, etc., and achieve light weight, anti-mite and antibacterial effects, The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of preparation method of natural ecological N type structure cotton, comprises the following steps:

[0024] a) Pre-treatment of hemp fiber: put the hemp fiber into an airtight warehouse, add Bacillus subtilis, ferment naturally at 30°C for 5 days, dry it until the moisture regain is 14%, and pack it for later use;

[0025] b) cut the dried hemp fibers into 45 mm by a fixed-length cutting machine, and then loosen and remove foreign matter;

[0026] C) adding 30% low-melting resin and 10% curly shaped fiber to the hemp fiber after impurity removal treatment, mixing, carding, pushing and swinging to form an N-shaped web, and heating and shaping to prepare an elastic soft material.

Embodiment 2

[0028] A kind of preparation method of natural ecological N type structure cotton, comprises the following steps:

[0029] a) Pre-treatment of hemp fibers: put the hemp fibers into a closed warehouse, add Bacillus subtilis, ferment naturally at 31°C for 5.2 days, dry until the moisture regain is 10%, and pack them for later use;

[0030] b) cut the dried hemp fibers into 46 mm by a fixed-length cutting machine, and then loosen and remove foreign matter;

[0031] C) Adding 15% low-melting resin and 15% curly-shaped fiber to the hemp fiber after impurity removal treatment, mixing, carding, pushing and swinging to form an N-shaped web, and heat-baked and shaped to prepare an elastic soft material.

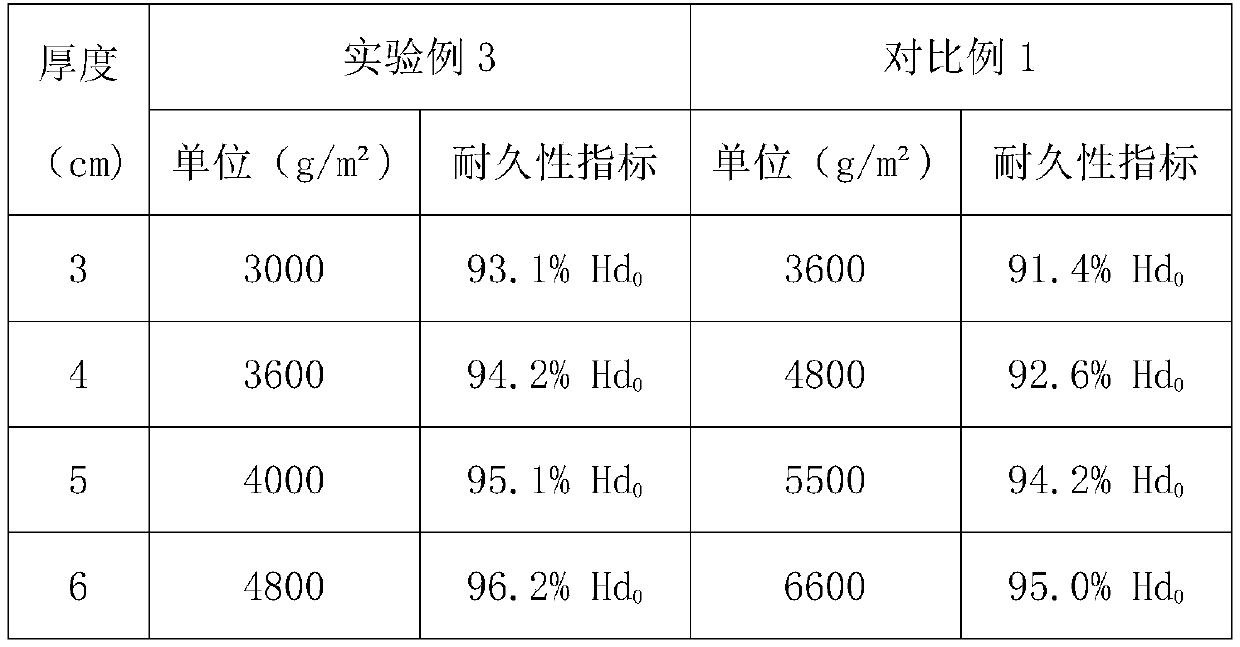

Embodiment 3

[0033] A kind of preparation method of natural ecological N type structure cotton, comprises the following steps:

[0034] a) Pre-treatment of hemp fiber: put the hemp fiber into an airtight warehouse, add Bacillus subtilis, ferment naturally at 32°C for 5.5 days, dry until the moisture regain is 8%, and pack it for later use;

[0035] b) cut the dried hemp fibers into 47 mm by a fixed-length cutting machine, and then loosen and remove foreign matter;

[0036] C) Add 20% low-melting resin and 20% curly-shaped fiber to the hemp fiber after impurity removal treatment, mix, card, push and swing N-type web, heat-baked and shaped to prepare an elastic soft material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com