Gas pressing device for improving oil gas fusion rate

A gas compression device and rate technology, which is applied in the field of gas dissolving devices, can solve the problems of low gas dissolving efficiency and indeterminable gas dissolving volume, etc., and achieve the effects of facilitating calculation, increasing the degree of disturbance, and improving the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

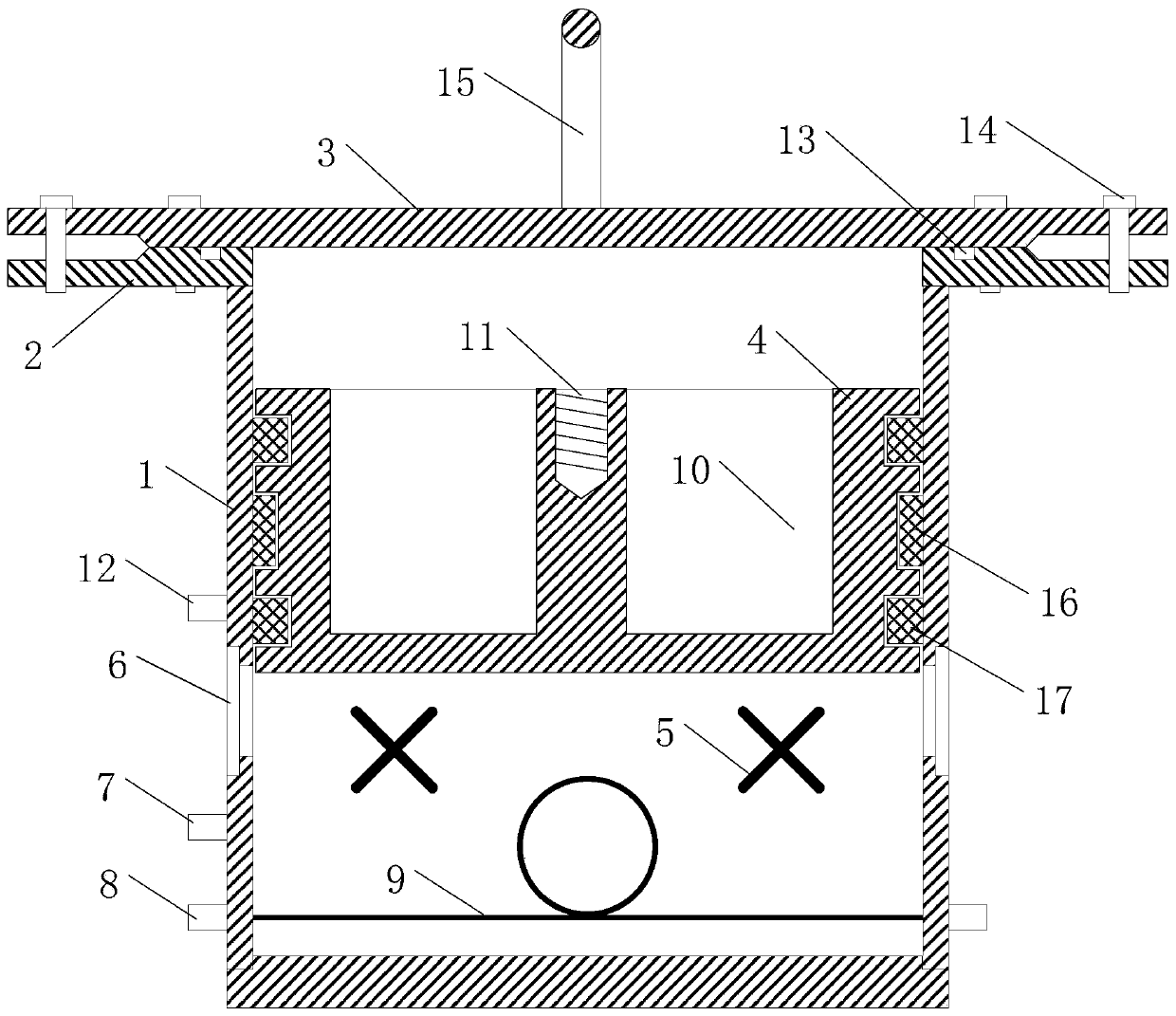

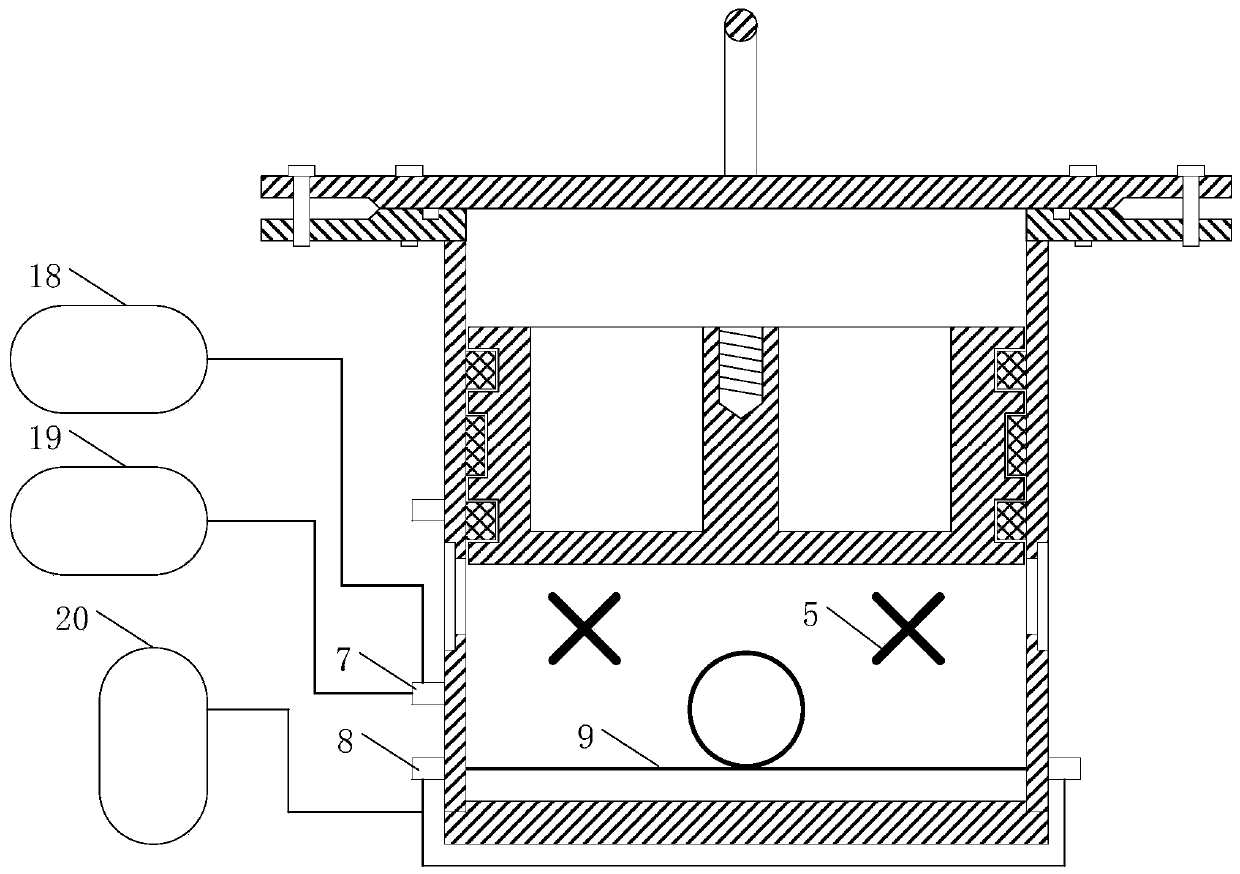

[0024] see figure 1 , which is a structural schematic diagram of an air compressing device for improving the oil-gas fusion rate provided by an embodiment of the present invention, the air compressing device includes:

[0025] Cylinder body 1, the bottom of cylinder body 1 is sealed, and the top of cylinder body 1 is provided with an annular connection seat 2, and the connection seat 2 is provided with a matching top cover 3, which can seal the top of cylinder body 1.

[0026] The cylinder body 1, the connection seat 2 and the top cover 3 provided by the embodiment of the present invention are made of 304 stainless steel (the chromium content is greater than 18%, and the nickel content is greater than 8%), which has good processability, high toughness and excellent corrosion resistance . The outer diameter of the cylinder 1 is 110mm, the inner diameter is 100mm, the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com