A high stability oled lighting screen body

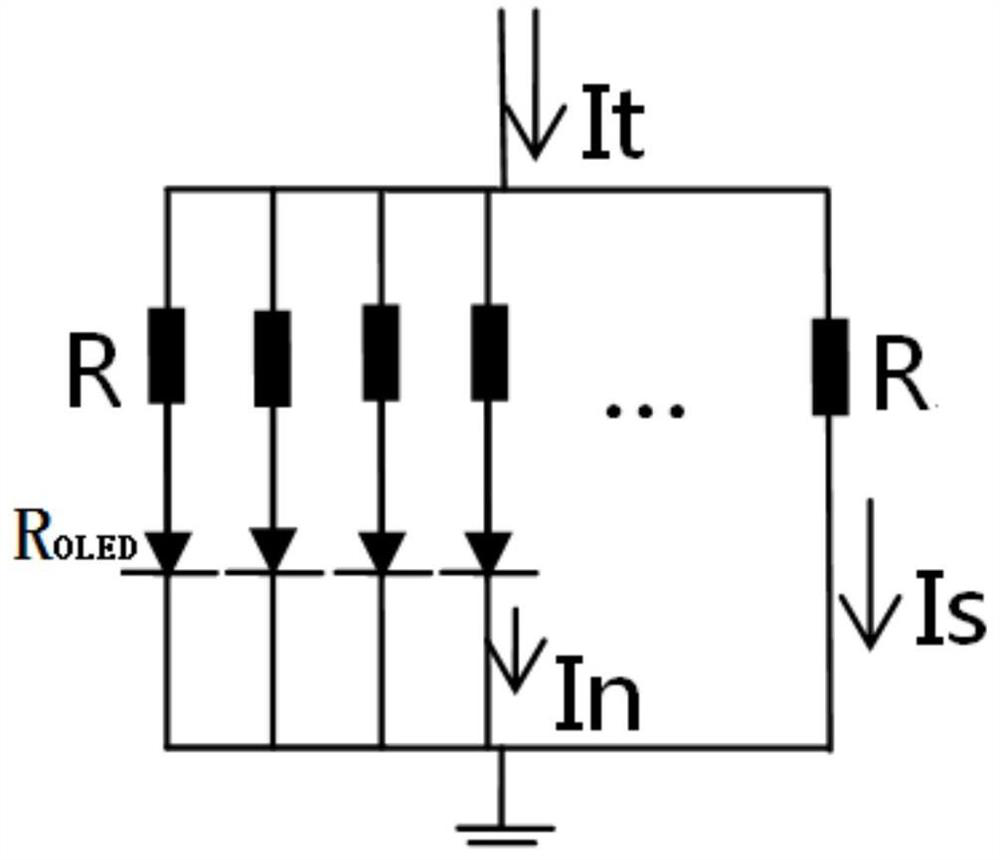

A high-stability, high-resistance technology, applied in the field of OLED screens, can solve the problems of less than this order of magnitude, the effect of short-circuit prevention is not obvious, and high heat, etc., to achieve the effect of preventing short-circuits in the burn area and improving the reliability of the screen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072]Set the number of divided pixels of the OLED screen to 10,000, the operating voltage of the OLED screen to 6V, and the corresponding current to 100mA, respectively connect 30Ω, 60Ω, 200Ω, and 600Ω fuses in series to each pixelated OLED circuit component, each The average passing current J of each pixel is 0.01mA. When there is a short-circuit defect point, the corresponding short-circuit point pixel current I of the short-circuit defect point is designed according to different resistances. s 66.6mA, 50.0mA, 23.1mA, 9.1mA, the corresponding I s The / J coefficients are 6667, 5000, 2308, 909 respectively; I s The smaller the value of / J, the more difficult it is for the fuse to achieve the fusing condition. The experiment shows that the 600 Ω fuse cannot achieve the purpose of fusing before the whole screen burns out. At the same time, due to Joule heat, the surrounding pixel areas of the fuse are about 50um, 100um, >500um in diameter, and the screen body fails. It can be ...

Embodiment 2

[0074] Set the number of divided pixels of the OLED screen to 100, the operating voltage to 6V, and the corresponding current to 100mA. 30Ω, 60Ω, 200Ω, and 600Ω fuses are connected in series to each pixelated OLED circuit component. The average of each pixel The passing current is 1mA. When there is a short-circuit defect point, the short-circuit point pixel current Is corresponding to the short-circuit defect point according to different resistance designs is 67.0mA, 50.4mA, 23.3mA, 9.22mA, and the corresponding Is / J coefficients are respectively The values are 67.0, 50.4, 23.3, 9.22; the smaller the Is / J value, the more difficult it is for the fuse to achieve the fusing condition. The experiment shows that the 600Ω fuse cannot achieve the purpose of fusing before the whole screen burns out. At the same time, due to Joule heat, the surrounding pixel areas of the fuse are about 50um, 100um, >500um in diameter, and the screen body fails. It can be seen that increasing the Is / J...

Embodiment 3

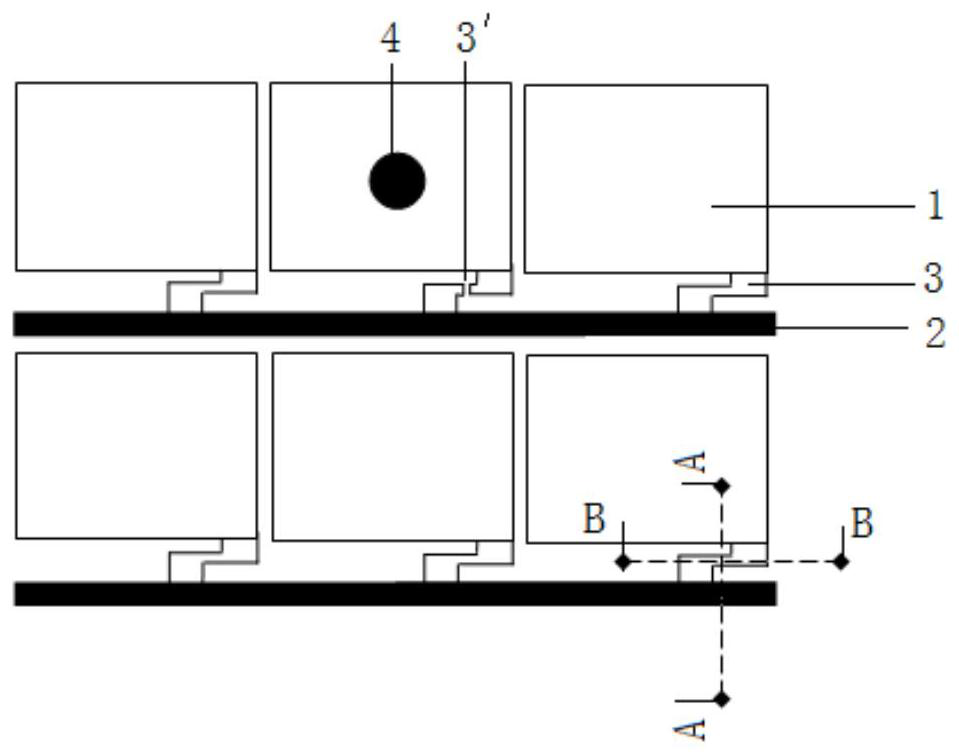

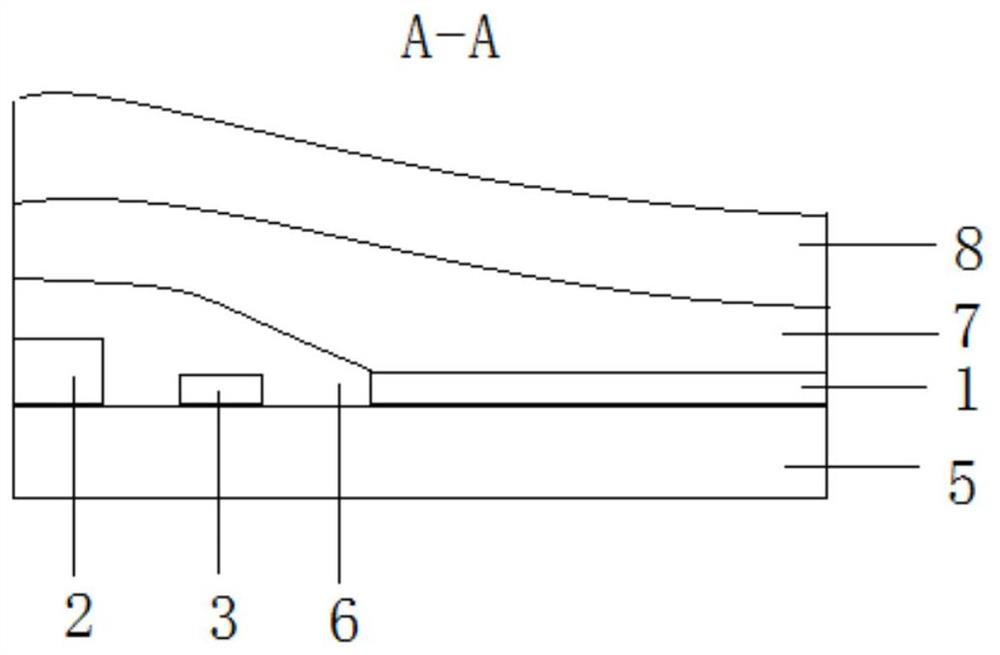

[0104] Anti-short circuit of the screen applied to the small area screen (small current 10-30mA)

[0105] The OLED screen device voltage is 6V, the current density of a single pixel is 0.0126mA, and there are 800, 1600, and 2400 pixels respectively, and the corresponding area is 144-433mm 2 , the low-resistance protector uses metallic conductive material with a melting point of 800°C, which uses a metal conductor with a wire width of 0.1um or a wire thickness of 10nm, and an insulating material layer with a melting point of 400°C is provided on the substrate under the low-resistance protector. The resistance of the low-resistance protector in the unit is negligible; the high-resistance protector is designed with a sheet resistance of 50Ω / □ with different aspect ratios, and the corresponding equivalent resistance is 500, 1000, 5000, 10000Ω; the short-circuit defect point equivalent The impedance settings are A-0, B-100, C-500, D-1000, and E-5000Ω. The experimental results are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com