Adding soil spraying base material used for greening rock steep slope

A technology of soil spraying and base material, which is applied in the fields of municipal and road slope engineering re-greening and mine restoration, can solve the problems of poor stability of the soil base material on steep slopes and the inability of rapid prototyping of the surface of the steep slope, and achieves low technical processing cost, The effect of small weight and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

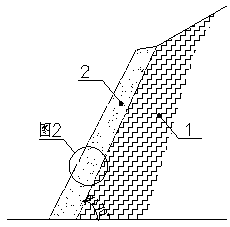

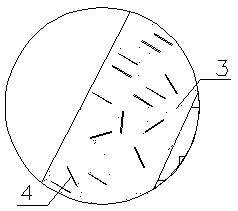

[0026] The guest soil base material suitable for greening of steep rock slopes in this embodiment is obtained by mixing and stirring matrix soil, curing agent, soil reinforcement, and water, wherein the matrix soil includes red clay, ceramsite 3 and humus, The curing agent includes cement, fly ash and gypsum. The soil reinforcement body 4 is rice straw. The mass parts of each component are: 50 parts of red clay, 10 parts of humus, 30 parts of ceramsite, 3 parts of cement, powder 1 part of coal ash, 1 part of gypsum powder, 2 parts of rice straw, 8 parts of water, and the water content of red clay is 5%, the particle size of ceramsite is 5~25mm, and the ceramsite 3 is saturated with water before mixing ;

[0027] Select 400kg of sieved red clay, 80kg of humus, 240kg of ceramsite, 24kg of cement, 8kg of fly ash, 8kg of gypsum powder, 16kg of rice straw, and 64kg of water, and add them to the mixer in turn, and stir for 9 minutes to obtain the guest soil substrate. The soil aggr...

Embodiment 2

[0030] The guest soil base material suitable for greening of steep rock slopes in this embodiment is obtained by mixing and stirring matrix soil, curing agent, soil reinforcement, and water, wherein the matrix soil includes red clay, ceramsite 3 and humus, The curing agent includes cement, fly ash and gypsum. The soil reinforcement body 4 is wheat straw. The mass parts of each component are: 60 parts of red clay, 15 parts of humus, 25 parts of ceramsite, 6 parts of cement, powder 2 parts of coal ash, 3 parts of gypsum powder, 3 parts of wheat straw, 10 parts of water, and the water content of red clay is 5%, the particle size of ceramsite is 5~25mm, and the ceramsite 3 is saturated with water before mixing ;

[0031] Select 480kg of sieved red clay, 120kg of humus, 200kg of ceramsite, 48kg of cement, 16kg of fly ash, 24kg of gypsum powder, 24kg of wheat straw, and 80kg of water, and then add them to the mixer in turn and stir for 10 minutes to obtain the guest soil substrate. ...

Embodiment 3

[0034] The guest soil base material suitable for greening of steep rock slopes in this embodiment is obtained by mixing and stirring matrix soil, curing agent, soil reinforcement, and water, wherein the matrix soil includes red clay, ceramsite 3 and humus, The curing agent includes cement, fly ash and gypsum. The soil reinforcement body 4 is wheat straw. The mass parts of each component are: 55 parts of red clay, 13 parts of humus, 28 parts of ceramsite, 5 parts of cement, powder 1.5 parts of coal ash, 2 parts of gypsum powder, 2.5 parts of rice straw, and 9 parts of water; and the water content of red clay is 4%, the particle size of ceramsite is 5-25mm, and the ceramsite 3 is saturated with water before mixing;

[0035] Select 495kg of sieved red clay, 117kg of humus soil, 252kg of ceramsite, 45kg of cement, 13.5kg of fly ash, 18kg of gypsum powder, 22.5kg of rice straw, and 81kg of water, and add them to the mixer in turn, and stir for 10 minutes to obtain the guest soil sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com