Method for manufacturing GH4169 low pressure turbine box forging with flange

A GH4169, low-pressure turbine technology, which is applied in the field of forging preparation, can solve the problems of sensitive forging process parameters, narrow deformation temperature range, high degree of alloying, etc., to solve the problem of structure difference and deformation, uniform internal structure, and high material utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

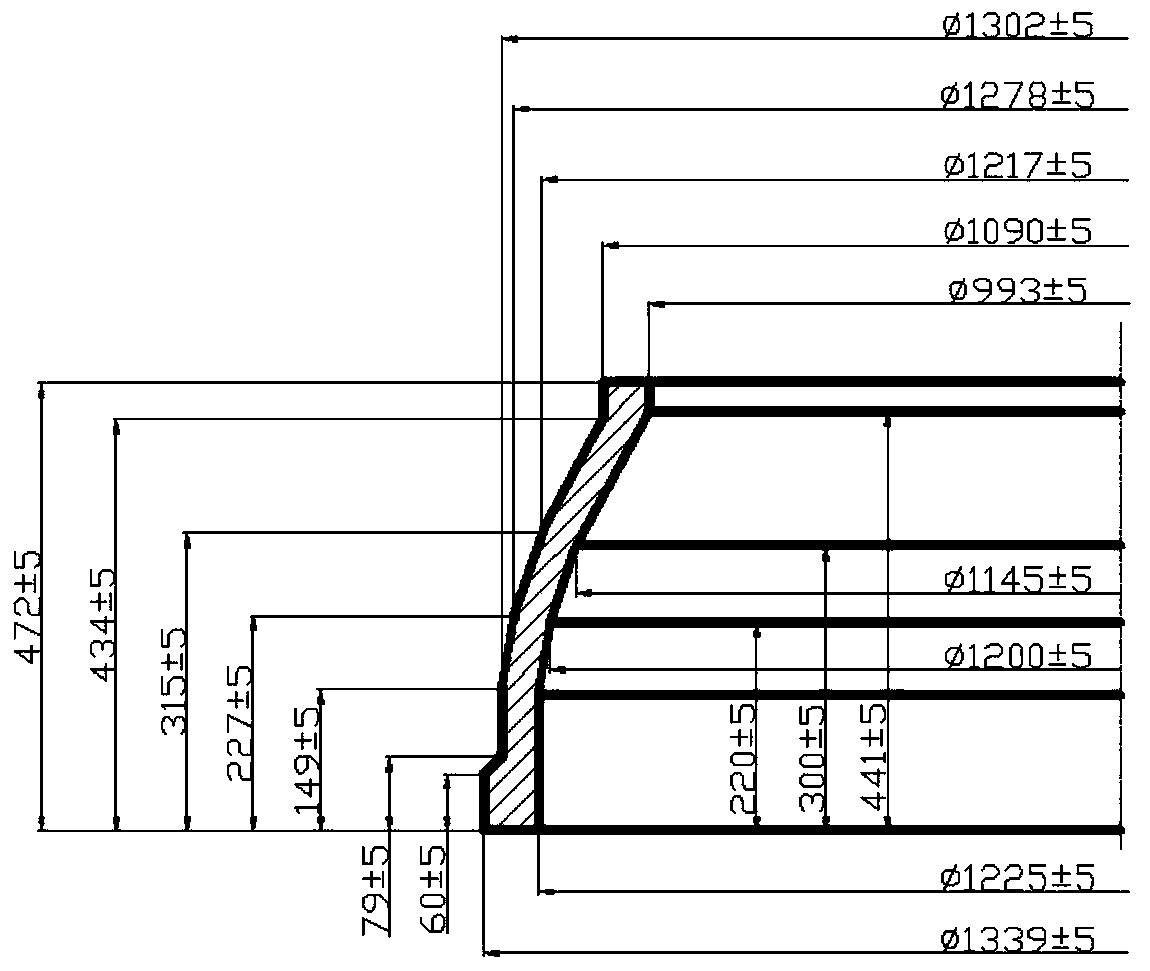

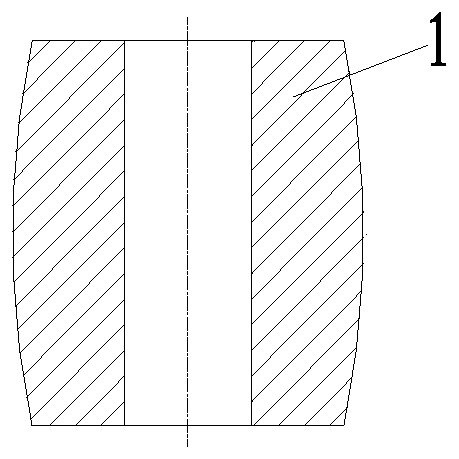

[0035] A method for manufacturing a flanged GH4169 low-pressure turbine case forging, comprising the following steps:

[0036] (1) Sawing: sawing the GH4169 bar according to certain specifications;

[0037] (2) Preheating: Heat the sawed GH4169 bar to 1030°C and keep it warm. The heat preservation is based on the effective thickness of the bar, and the heat preservation is 6 minutes per 10mm effective thickness;

[0038] (3) Upsetting and punching: heat the heat-preserved GH4169 bar at 1030°C to ≥1030°C for upsetting and punching, the final forging temperature is ≥870°C, and the pressure used for upsetting and punching is 3500T , the deformation of the bar after upsetting and punching is 32%, and the ring blank is obtained;

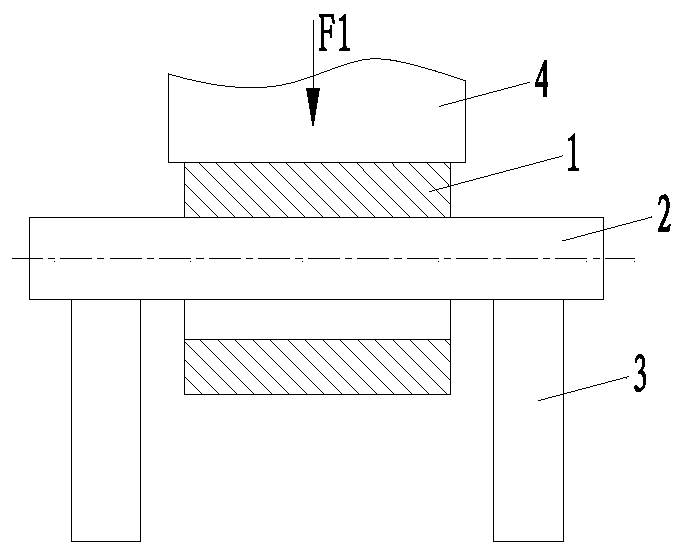

[0039] (4) Horse frame reaming: heat the ring blank at 1030°C to ≥1030°C, put it on the horse bar, put it on the horse frame, and under the drive of the press, the upper anvil exerts pressure F on the ring blank 1 (3500T), at the same time, the manipula...

Embodiment 2

[0045] A method for manufacturing a flanged GH4169 low-pressure turbine case forging, comprising the following steps:

[0046] (1) Sawing: sawing the GH4169 bar according to certain specifications;

[0047] (2) Preheating: Heat the sawed GH4169 bar to 1040°C and keep it warm. The heat preservation is based on the effective thickness of the bar, and keeps warm for 6 minutes per 10mm effective thickness;

[0048] (3) Upsetting and punching: heat the heat-preserved GH4169 bar at 1040°C to a degree ≥ 1030°C and then perform upsetting and punching. The final forging temperature is ≥ 870°C. The pressure used for upsetting and punching is 4000T, the deformation of the bar after upsetting and punching is 32%, and the ring blank is obtained;

[0049] (4) Horse frame reaming: heat the ring billet at 1040°C to ≥1030°C, put it on the horse bar, put it on the horse frame, and under the drive of the press, the upper anvil exerts pressure on the ring billet F 1 (4000T), at the same time, t...

Embodiment 3

[0055] A method for manufacturing a flanged GH4169 low-pressure turbine case forging, comprising the following steps:

[0056] (1) Sawing: sawing the GH4169 bar according to certain specifications;

[0057] (2) Preheating: Heat the sawed GH4169 bar to 1050°C and keep it warm. The heat preservation is based on the effective thickness of the bar, and keeps warm for 6 minutes per 10mm effective thickness;

[0058] (3) Upsetting and punching: heat the heat-preserved GH4169 bar at 1050°C to ≥1030°C for upsetting and punching, the final forging temperature is ≥870°C, and the pressure used for upsetting and punching is 4200T , the deformation of the bar after upsetting and punching is 32%, and the ring blank is obtained;

[0059] (4) Horse frame reaming: heat the ring billet at 1050°C to ≥1030°C, put it on the horse bar, put it on the horse frame, and drive the upper anvil to exert pressure F on the ring billet under the drive of the press 1 (4200T), at the same time, the manipulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com