Segmented wave-absorbing honeycomb composite material with corrugated structure and preparation method thereof

A composite material and corrugated technology, applied in the field of wave-absorbing materials, can solve problems that do not meet the development trend of thin, light, wide, and strong wave-absorbing materials, and thick wave-absorbing honeycomb sandwich composite materials, etc., to achieve light weight and load-bearing Strong, good environmental resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

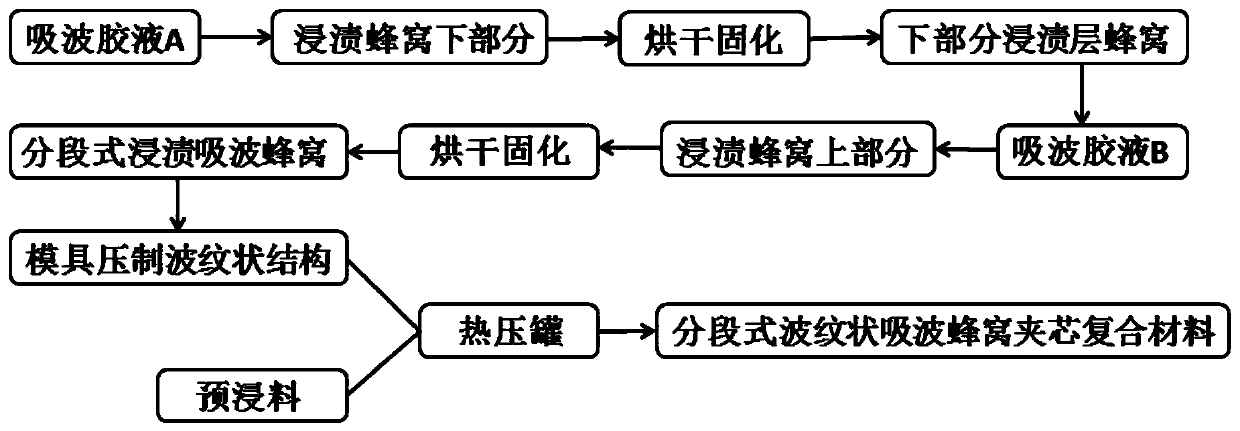

[0031] Example: Preparation of segmented corrugated wave-absorbing honeycomb sandwich composite material in the upper part of carbonyl iron and lower part of carbon black

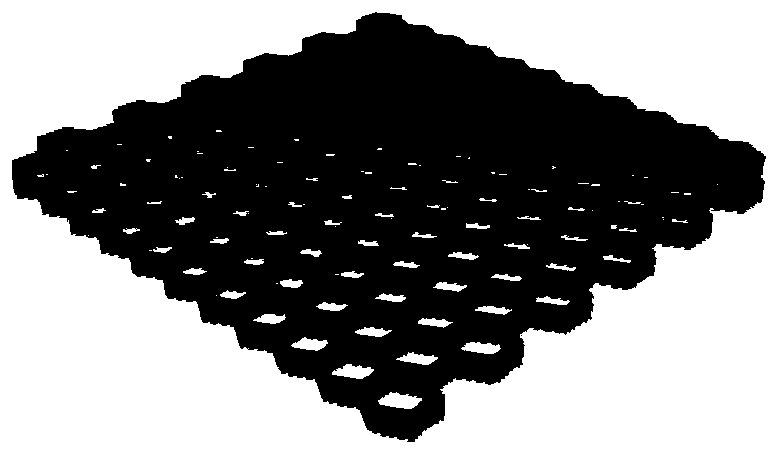

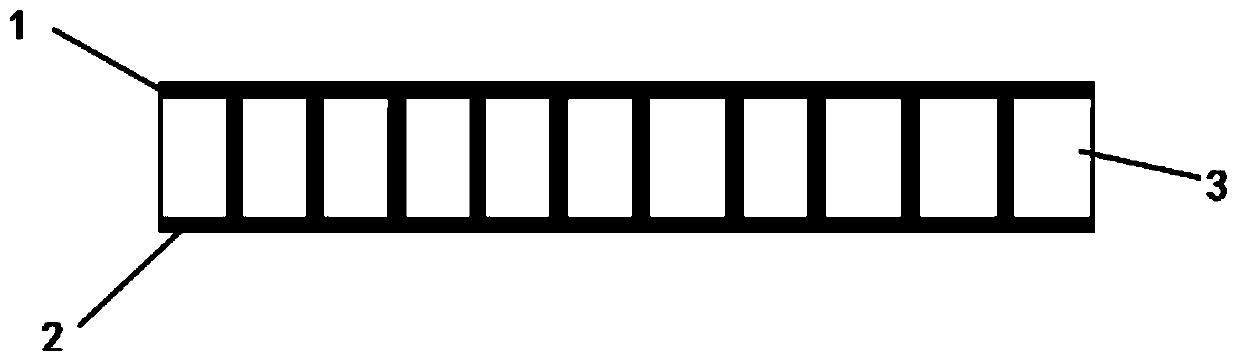

[0032] A wave-absorbing honeycomb sandwich composite material, including wave-absorbing honeycombs and matching panels placed on the upper and lower sides of the wave-absorbing honeycomb; the honeycomb core material is impregnated in stages, and the upper part is impregnated with a wave-absorbing glue containing carbonyl iron. 2.5mm, the lower part is impregnated with a wave-absorbing glue containing carbon black, the impregnation height is 2.5mm; the wave-absorbing honeycomb honeycomb wall impregnation layer is a corrugated structure, the width of the corrugation line is 0.5mm, the corrugation line is 3, the corrugation line is horizontal Arranged in parallel; the honeycomb core material is aramid paper honeycomb, thickness 5mm, cell size 1.83mm, inscribed circle diameter 3.2mm, density 29kg / m 3 ; The matching...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com