Expandable small-sized chassis type battery swap station applying lifter

A technology for lifts and power stations, used in charging stations, conveyors, electric vehicles, etc., can solve the problems of inability to expand the scale, large area, low degree of automation, etc., and achieves easy installation and later maintenance. Small and easy to transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

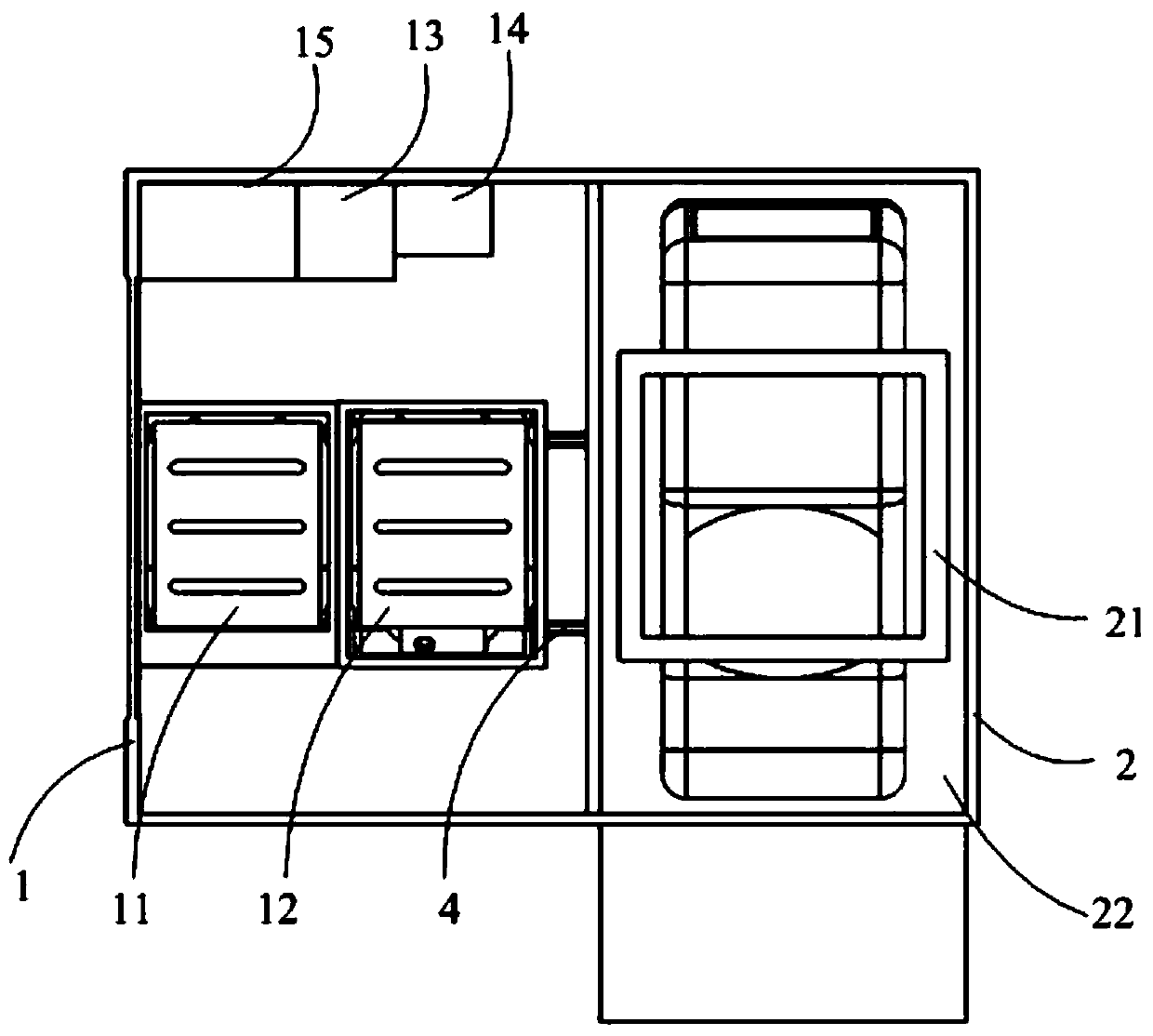

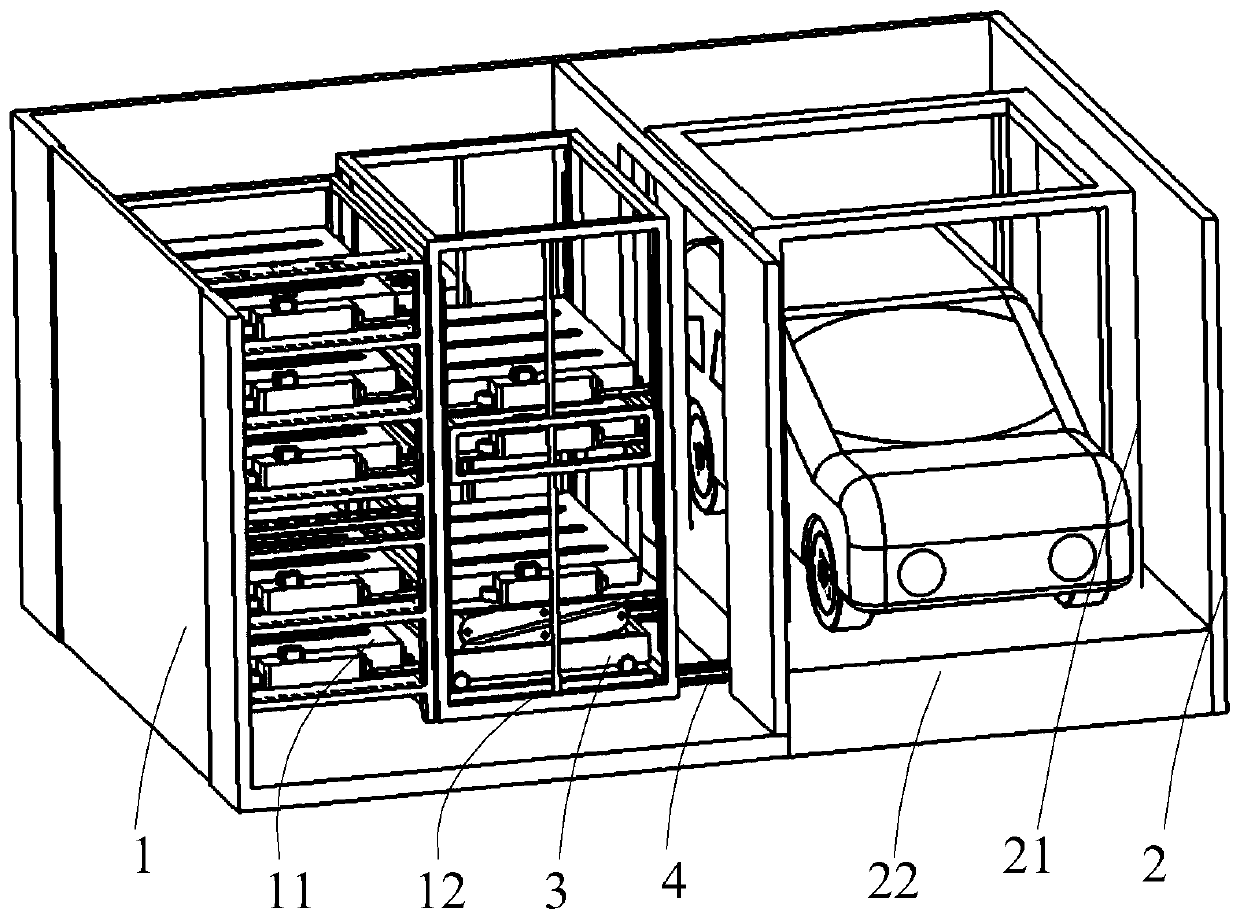

[0054] see figure 1 and figure 2 , the present invention is an expandable small-scale chassis-type battery-swapping station using a lift, and its structure includes a charging container 1 , a battery-swapping container 2 and an RGV battery-swapping trolley 3 .

[0055] The charging container 1 and the battery replacement container 2 are arranged side by side, and the RGV battery replacement trolley 3 is arranged on the first lateral movement guide rail 4 across the two; the battery replacement container 2 is arranged in a direction perpendicular to the first lateral movement guide rail 4. access channel.

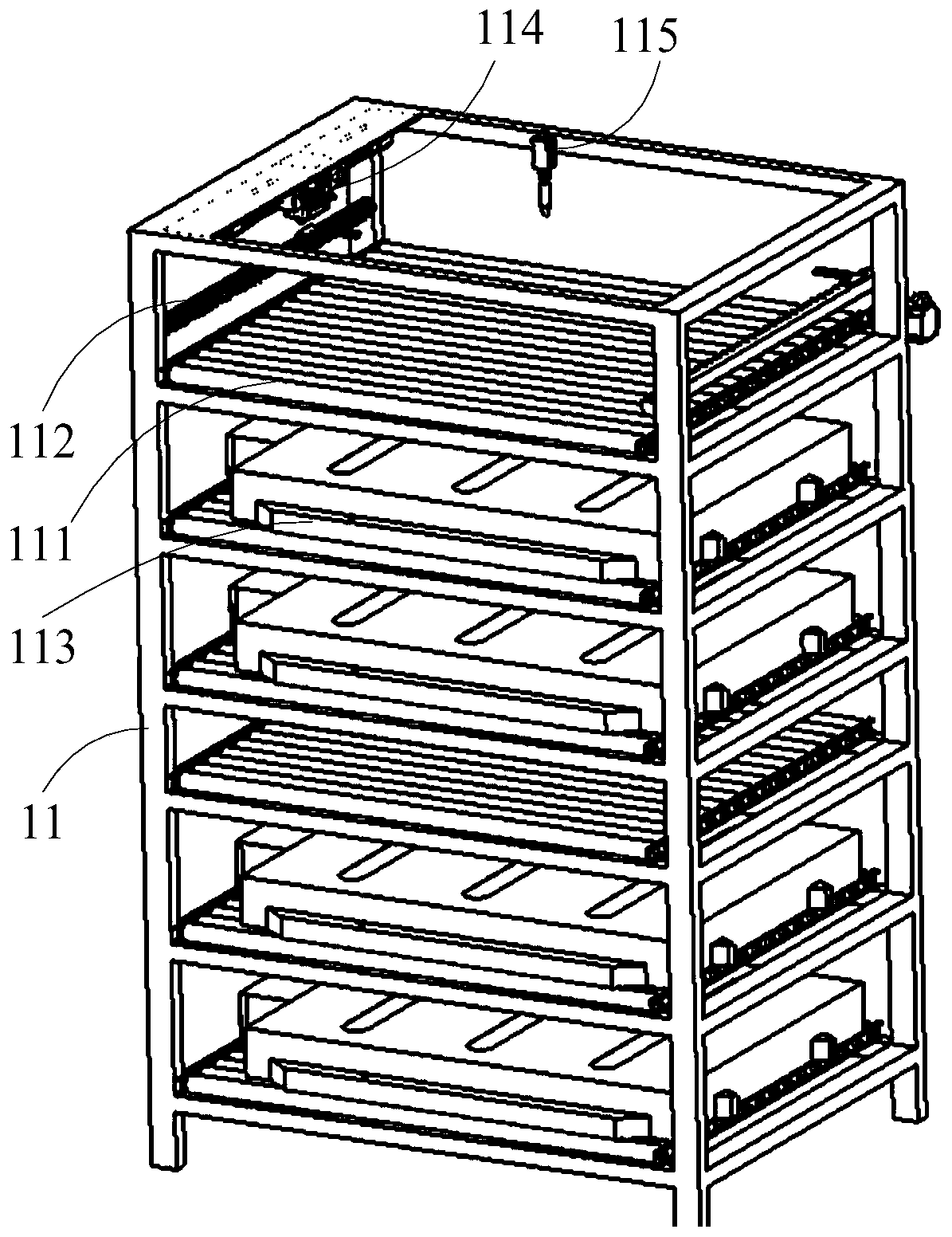

[0056] Inside the charging container 1 are arranged side by side a rechargeable battery rack 11 , an elevator 12 , a power distribution system 13 , a main control system 14 and a charging system 15 ; The above-mentioned power distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com