Raw material gas well mouth pressurization post-processing system and method

A raw gas and pretreatment technology, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of weakened slug flow capture capacity, impact on use efficiency, and difficulty in simultaneous drainage, etc. The effect of adaptability, guaranteeing operation ability and guaranteeing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

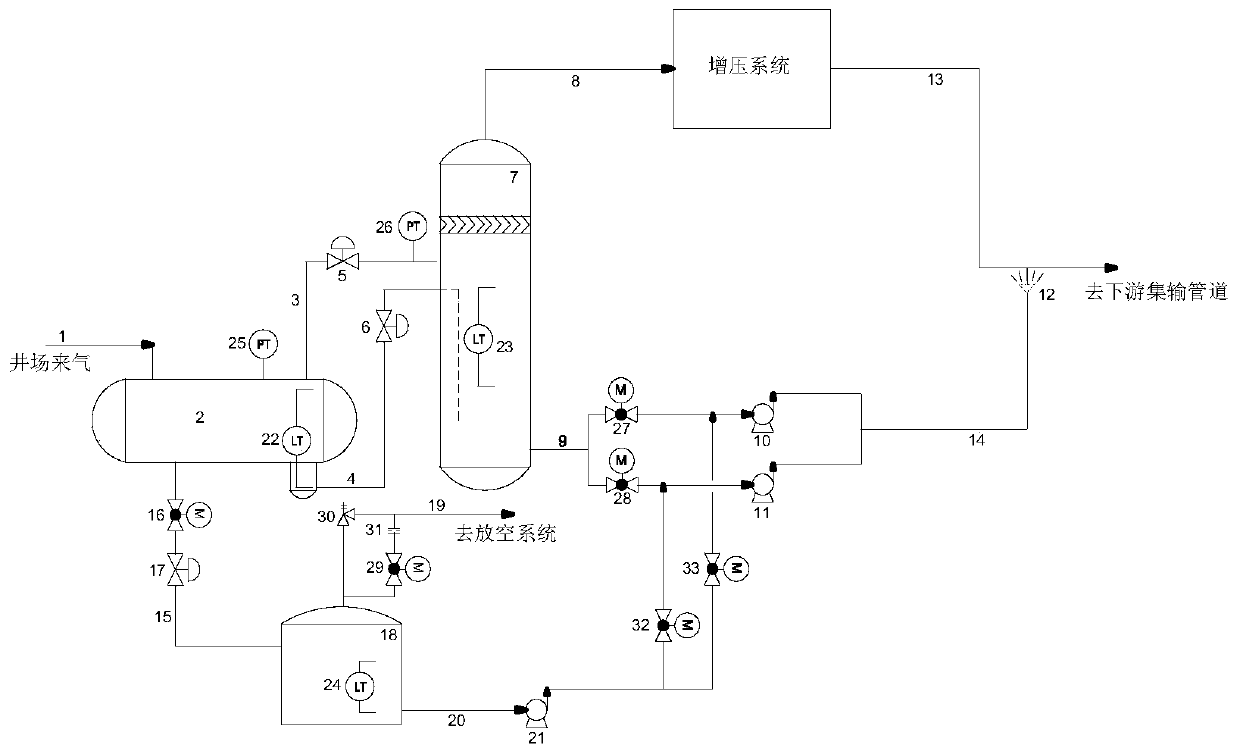

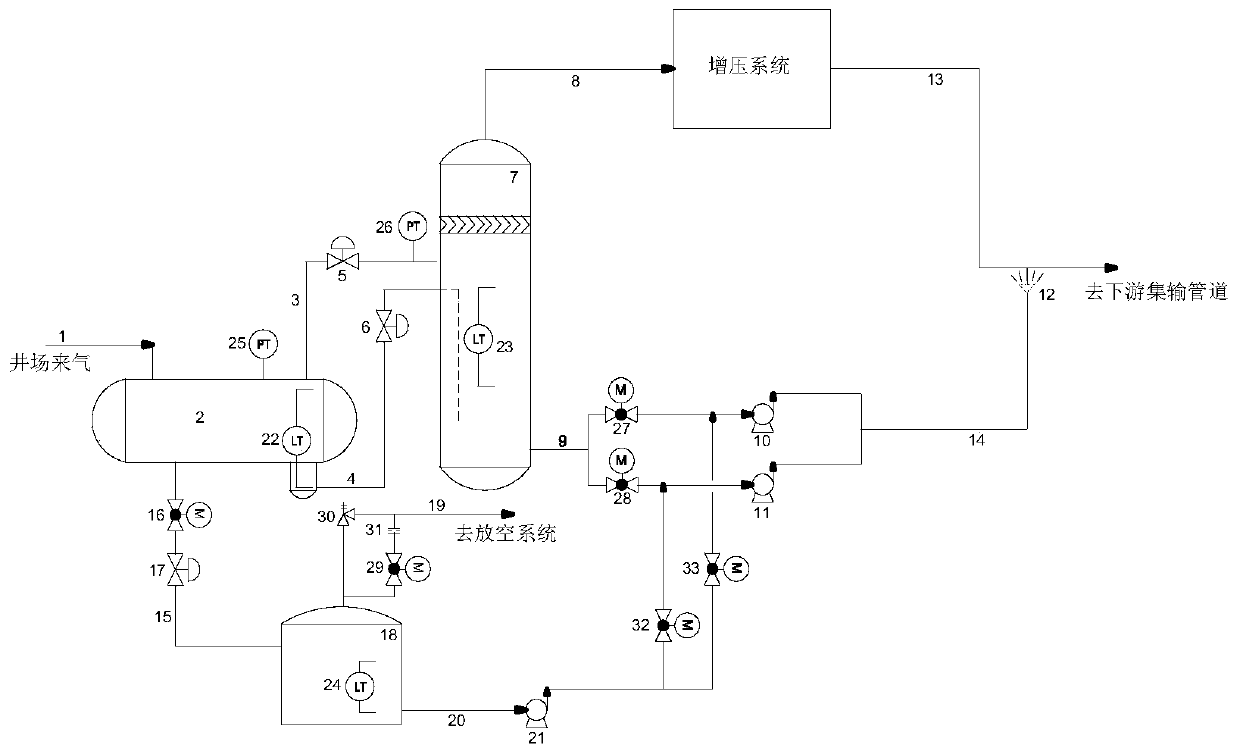

[0023] The invention discloses a raw material gas pretreatment system before wellhead pressurization, including a high-efficiency slug flow capture system, a vertical gas-liquid separation system, a hydrocarbon liquid pump system, an emergency liquid drainage system, a monitoring system, a logic control system and the like.

[0024] A raw material gas pretreatment system before wellhead pressurization, mainly including: inlet pipe section 1, slug flow trap 2, gas phase pipeline 3, liquid phase pipeline 4, regulating valve 5, regulating valve 6, vertical gas-liquid separator 7. Gas phase outlet pipeline 8, liquid phase outlet pipeline 9, hydrocarbon liquid centrifugal pump 10, hydrocarbon liquid centrifugal pump 11, atomizer 12, gas phase boosted pipeline 13, liquid phase boosted pipeline 14, discharge pipeline 15, Electric ball valve 16, regulating valve 17, low pressure storage tank 18, vent pipe 19, liquid phase pipe 20, hydrocarbon liquid relay pump 21, liquid level transmit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap