A monocular vision size measurement method based on a linear motion module

A motion module and monocular vision technology, applied in the field of three-dimensional measurement, can solve the problems of static workpiece, complicated calibration process of structured light measurement sensor, high equipment cost, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

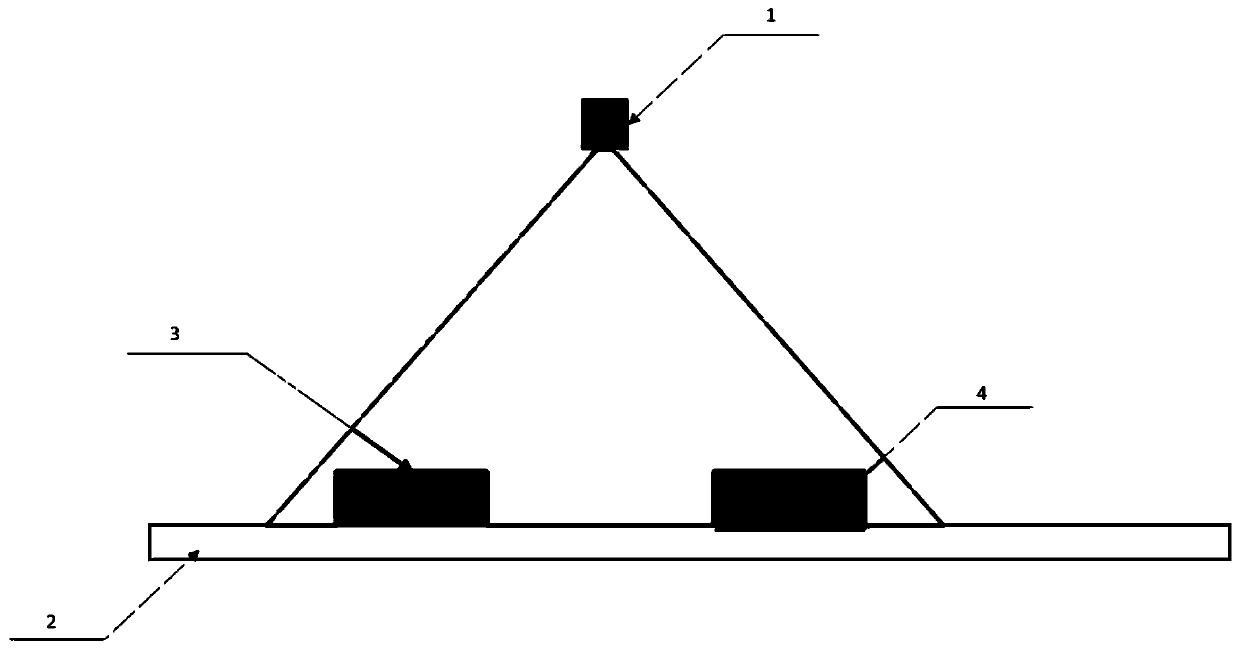

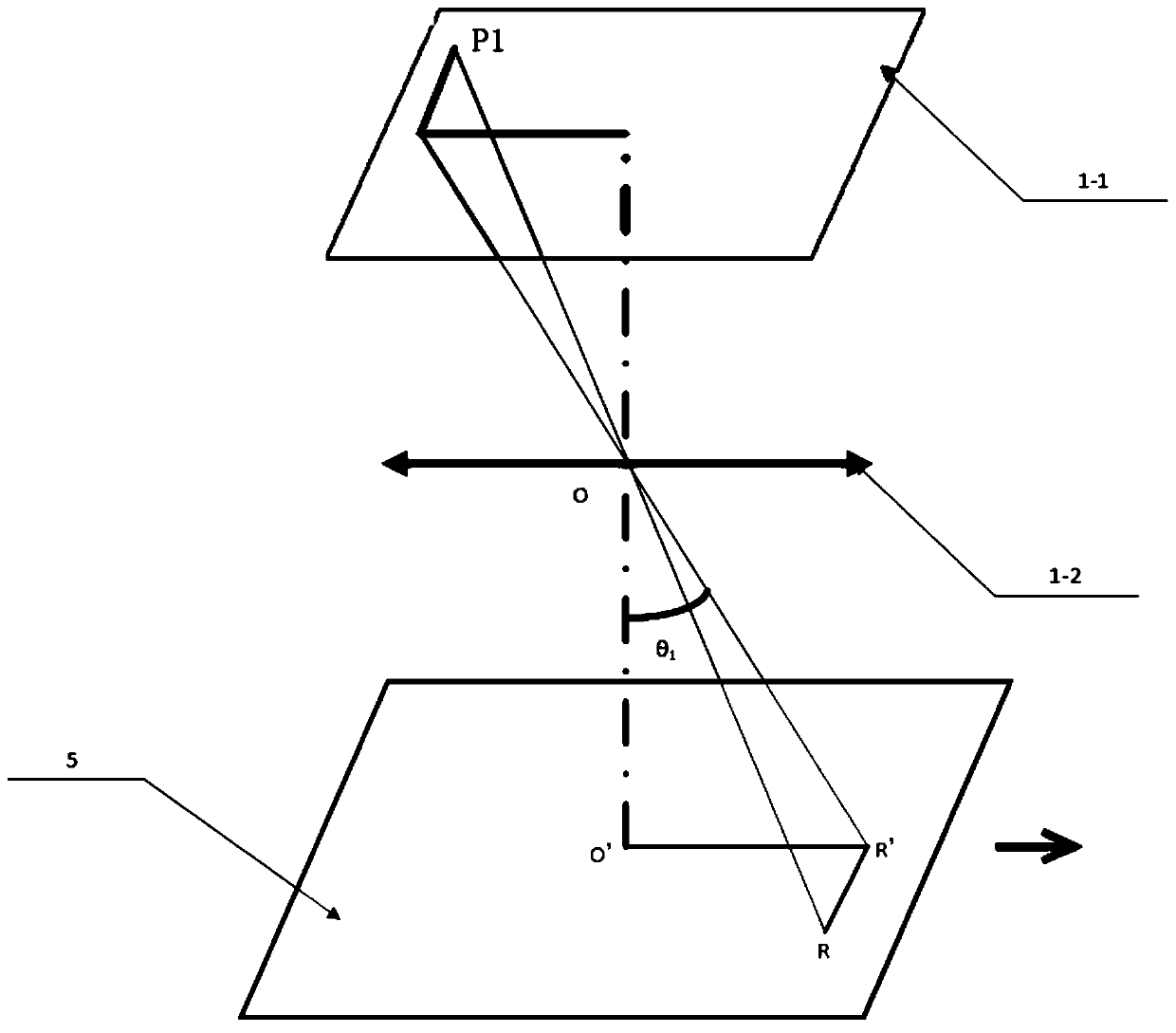

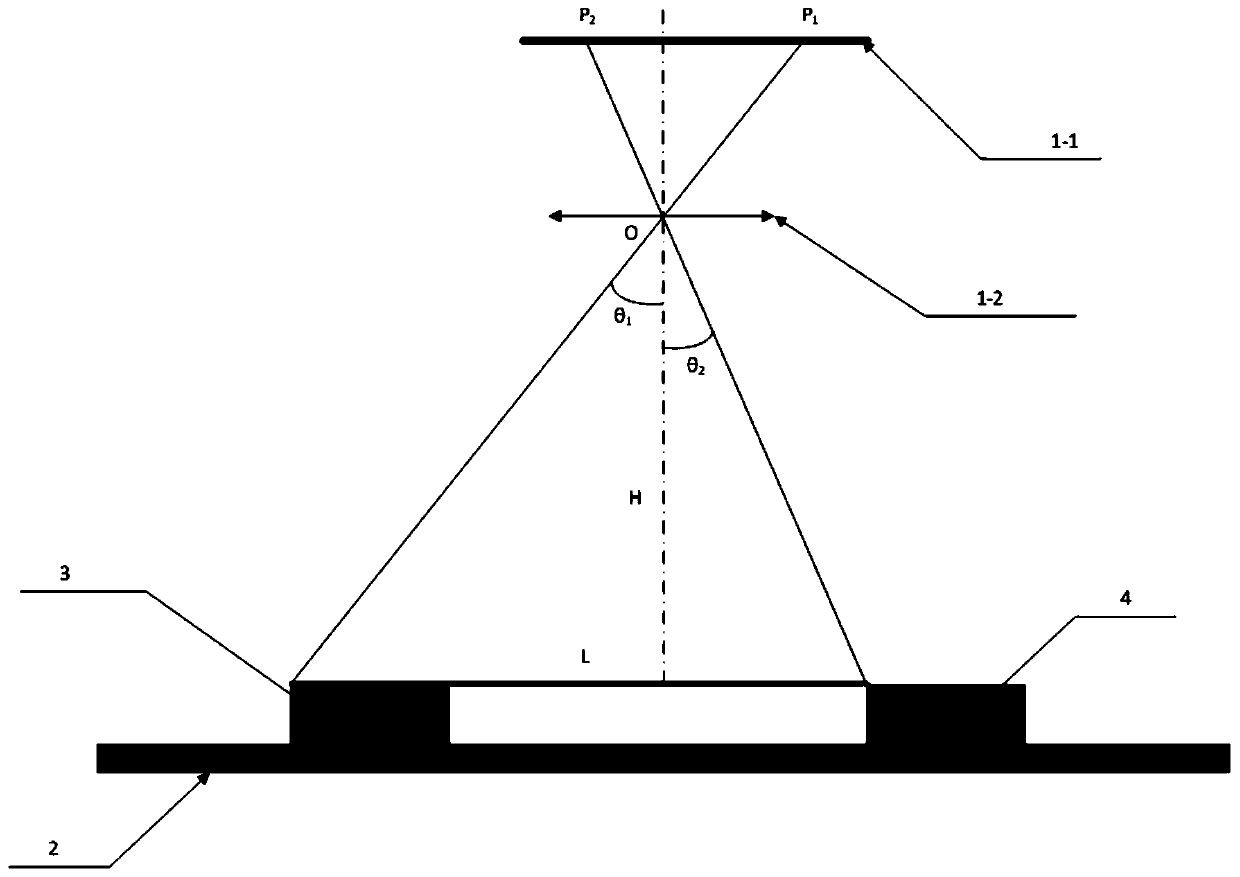

[0024] The size measurement method of monocular vision based on linear motion module, see Figure 1-Figure 3 , the monocular camera 1 is set directly above the linear motion module 2, and two points at different positions in the linear advance direction of the linear motion module within the coverage area of the selected lens of the monocular camera 1 respectively photograph two positions of the workpiece at the corresponding positions. After that, according to the two images, the three-dimensional size of the workpiece is reconstructed through the external processor part. When reconstructing the three-dimensional size of the workpiece, it includes the following steps:

[0025] a According to the calibration file of the monocular camera, perform distortion correction on the two images;

[0026] b Use mature image processing algorithms such as feature point matching, phase matching, and area matching to match artifacts in the two images, and establish the position corresponde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com