Broadband high-gain circularly polarized microstrip antenna

A microstrip antenna and high-gain technology, which is applied to antenna grounding devices, antenna arrays that are powered independently, and antenna grounding switch structural connections, etc., can solve the problem of increasing antenna feed loss, increasing processing complexity, and increasing antenna size, etc. problem, to achieve the effect of wide axial ratio bandwidth, reduce lateral leakage, and reduce feed loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

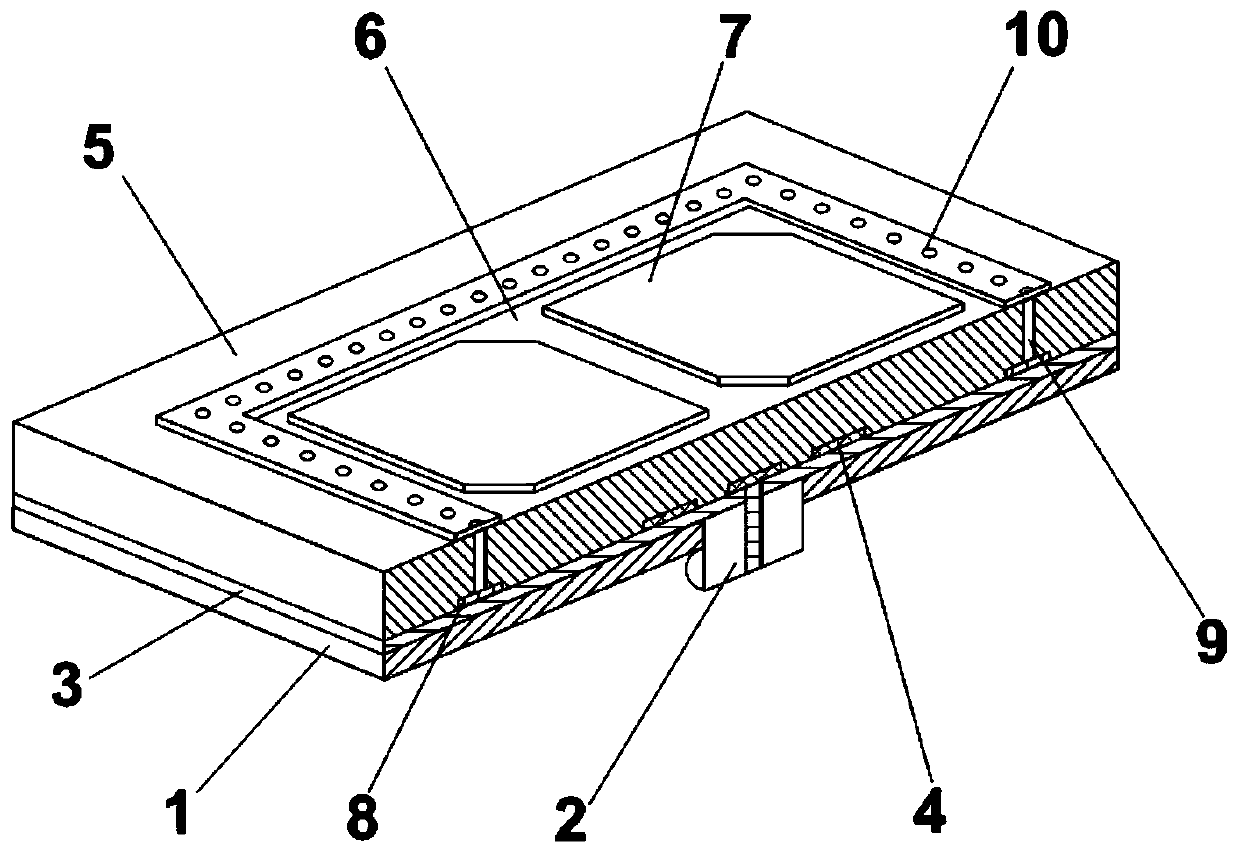

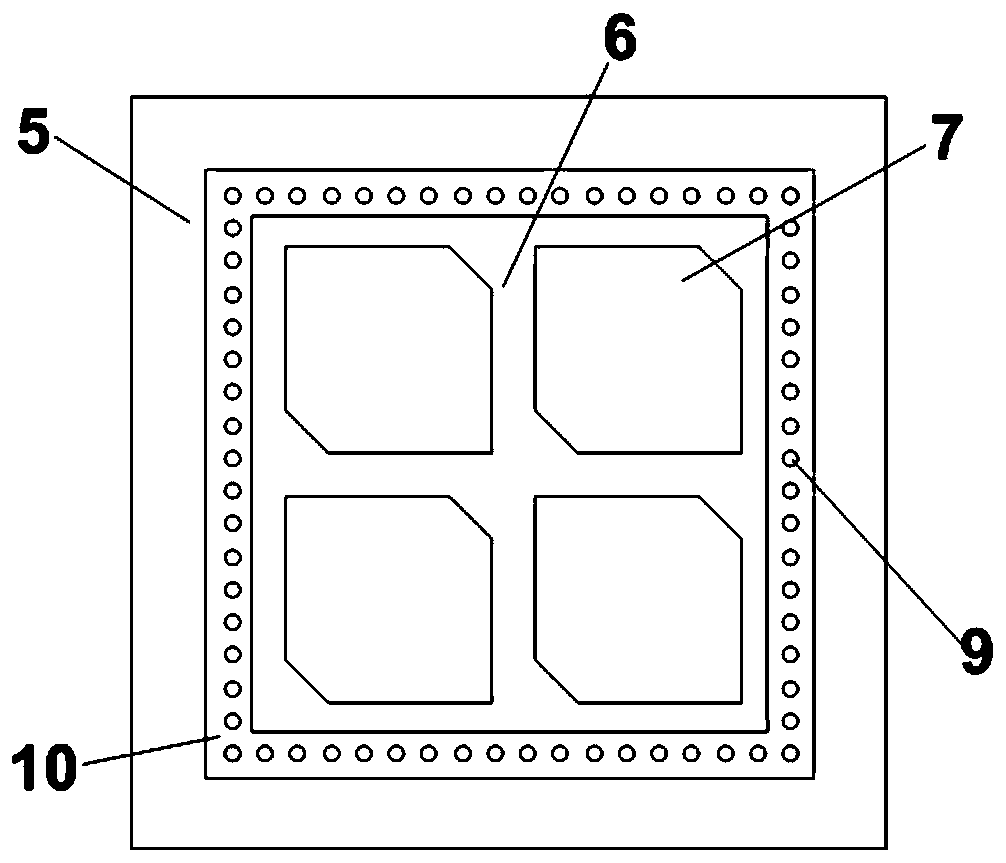

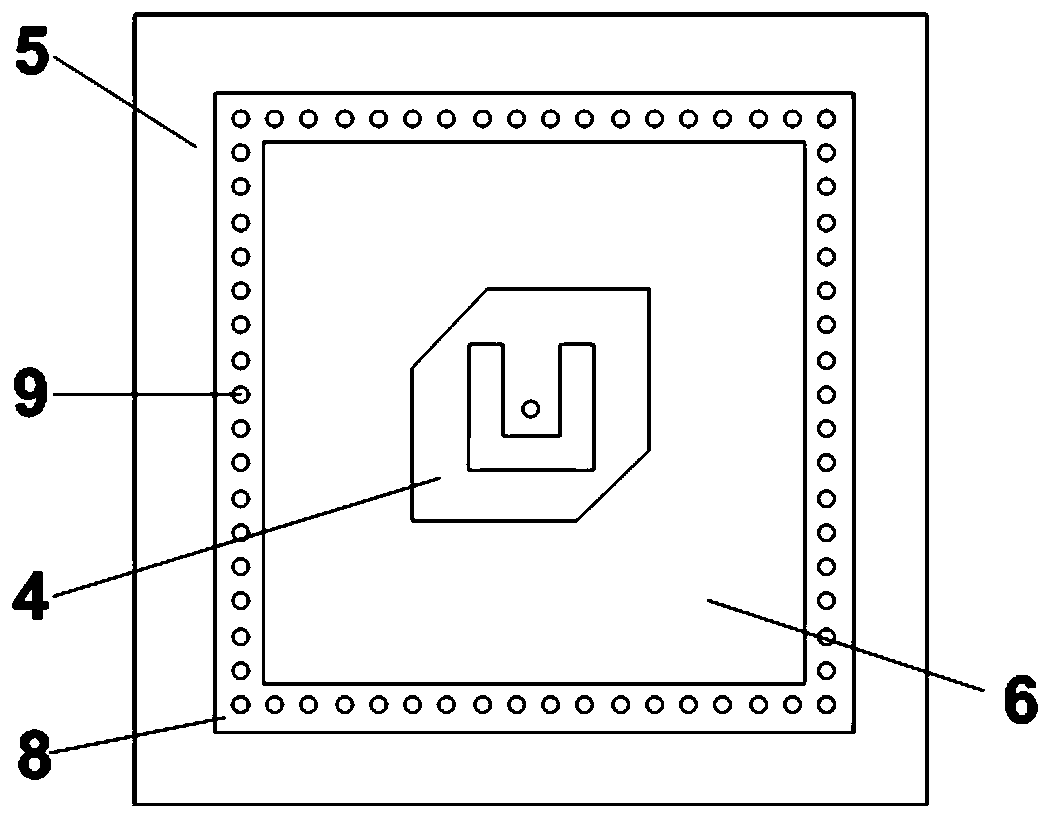

[0028] figure 1 Shown is the schematic diagram of the layered structure of the antenna of the present invention, as can be seen from the figure, the wide-band high-gain circularly polarized microstrip antenna proposed by the present invention includes: floor 1, feed coaxial 2, bottom dielectric substrate 3, cut corner U-shaped groove microstrip 4, top layer dielectric substrate 5, substrate integrated waveguide square cavity 6, microstrip radiation unit 7; the microstrip antenna of the present invention can be processed by common double-layer microstrip printed board technology, and can also be processed by LTCC Craft realized.

[0029] Among them, the structural floor (1) is located at the bottom of the antenna and is made of metal, the bottom dielectric substrate 3 is located on the upper layer of the floor 1 and is in close contact, the top dielectric substrate 5 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com