Fixed-bed reactor for isoparaffin synthesis, multi-stage material inlet equipment used for reactor and method for synthesizing isoparaffin

A technology for synthesizing reactors and feeding equipment, applied in chemical instruments and methods, hydrocarbon oil cracking, chemical/physical processes, etc. Inactivation and other problems, to achieve the effect of simple structure, small pressure drop and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Embodiment 1 illustrates the mixing effect of the multistage feeding equipment provided by the present invention.

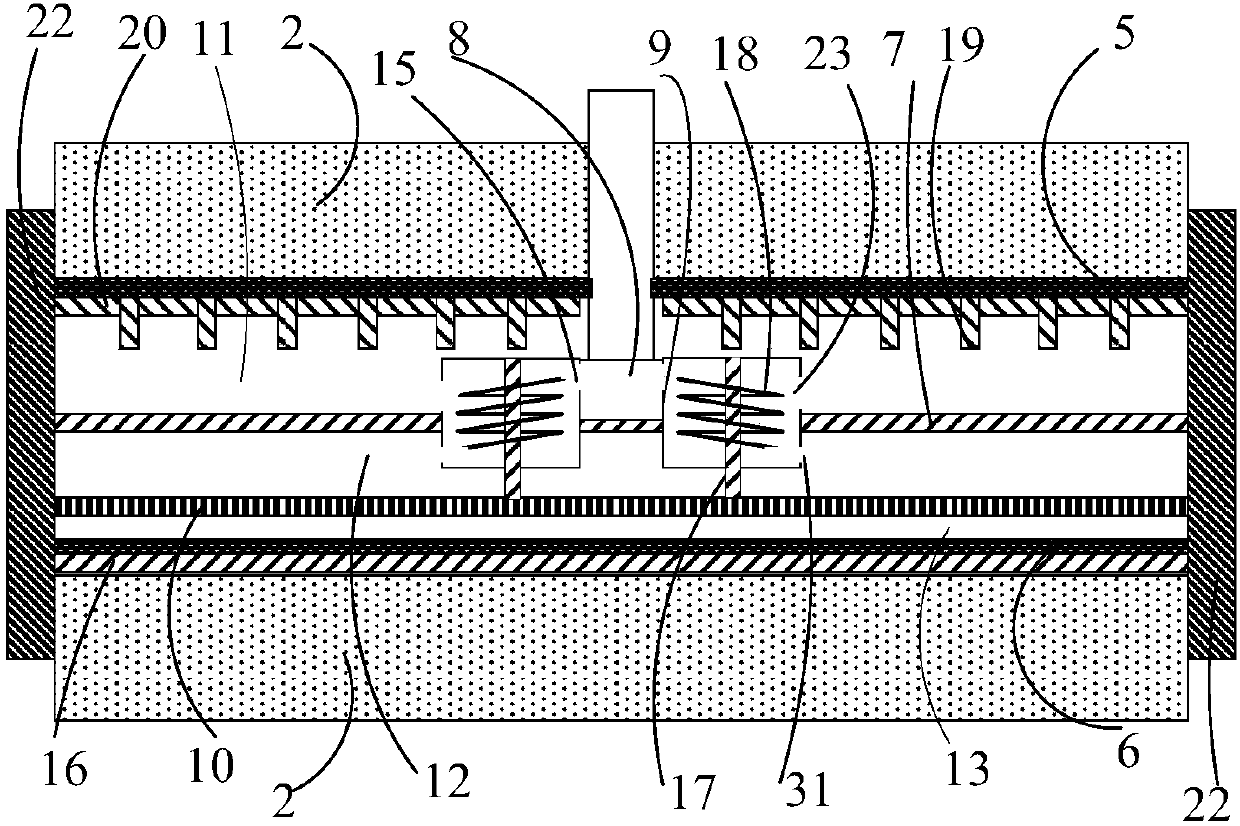

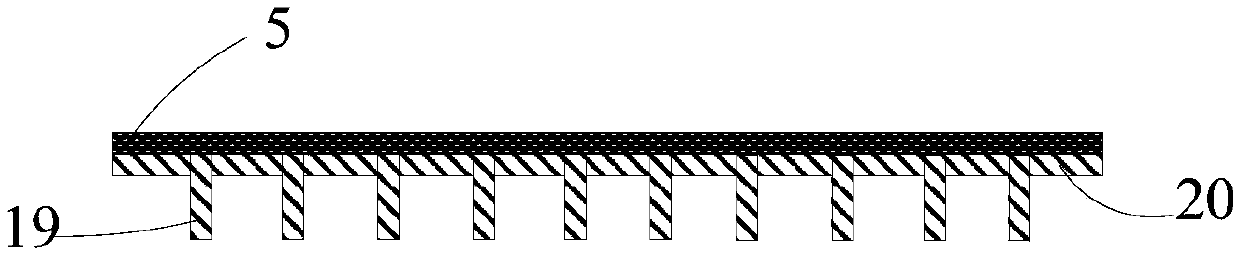

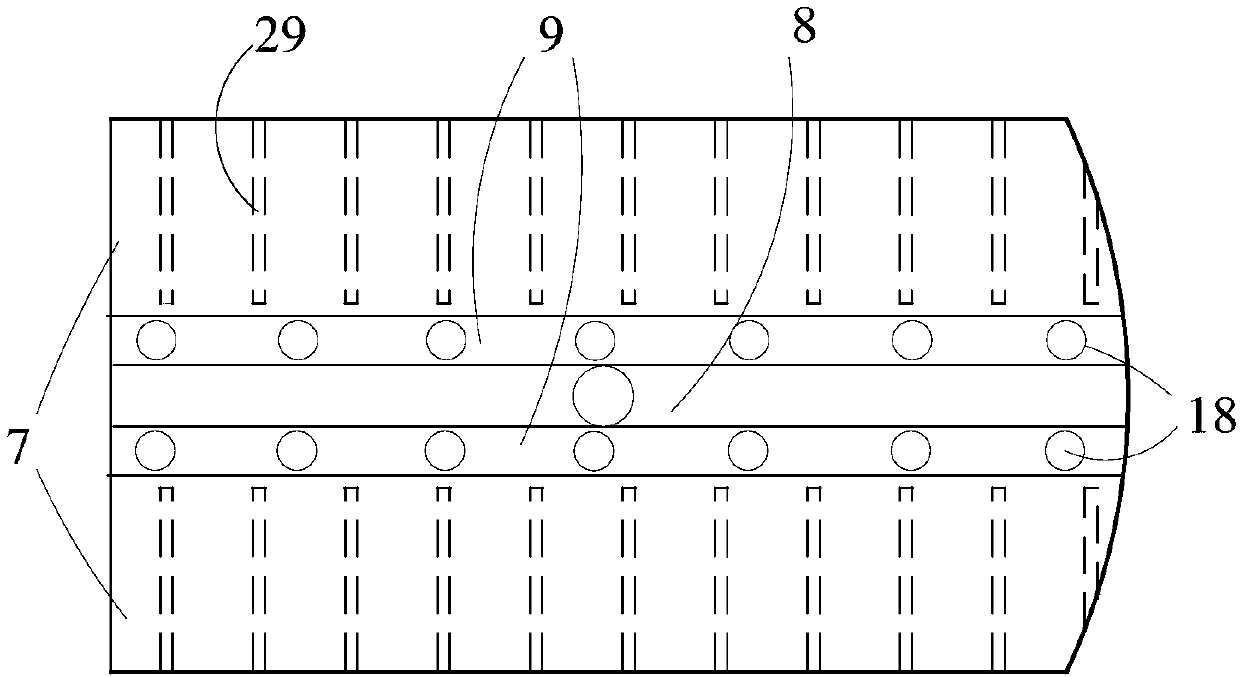

[0088] Experimental method: use the multi-stage feeding equipment provided by Fangming, the specific structure is the same as figure 1As shown, the ratio of the cross-sectional area of the fluid collecting plate 7 to the total cross-sectional area of the fluid mixing chamber 9 is 47.5:1, and the side plate of the fluid mixing chamber 9 of the multistage feeding device has a third opening 15 in the shape of a small hole. The diameter of the third opening is 5 mm, the distance between adjacent third openings is 30 mm, and the ratio of the total opening area on the feed distribution pipe 8 to the total cross-sectional area of the fluid mixing chamber 9 is 1:25. The height of the fluid mixing chamber 9 is 100mm, and the shape of the cross-sectional area is circular. The fluid mixing chamber 9 and the fluid distribution plate 10 are spaced apart and the d...

Embodiment 2

[0100] in with Figure 8 The solid acid alkylation reaction is carried out on a similar three-stage feed fixed-bed experimental device as shown. Among them, the inner diameter of the shell of the fixed-bed reactor is 200 mm, and the height of each catalyst bed is 1.5 m, that is, the total height of the effective catalyst bed is 4.5 m. Multi-stage feeding equipment is figure 1 As shown, the specific parameters are the same as in Example 1, and the overall height of the equipment is 260mm (that is, the distance from the bottom of the upper catalyst bed to the top of the next catalyst bed). The fresh raw material for the reaction is a mixture of isobutane and butene, wherein the mixture of isobutane and butene with an alkanes ratio of 30:1 is fed from the feed line of the distributor, and the molar ratio of alkanes in the reactor is 900:1 , the superficial flow velocity of the liquid mixture in the reactor is 0.02m / s, and the weight space velocity of the olefin is 0.05h -1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com