Self-water permeable anti-surface water accumulation highway concrete

A technology of permeable concrete and concrete, applied in the field of concrete, can solve the problems of water on the surface of concrete, uneven distribution of pores, difficulty in balancing water permeability and strength, etc., and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

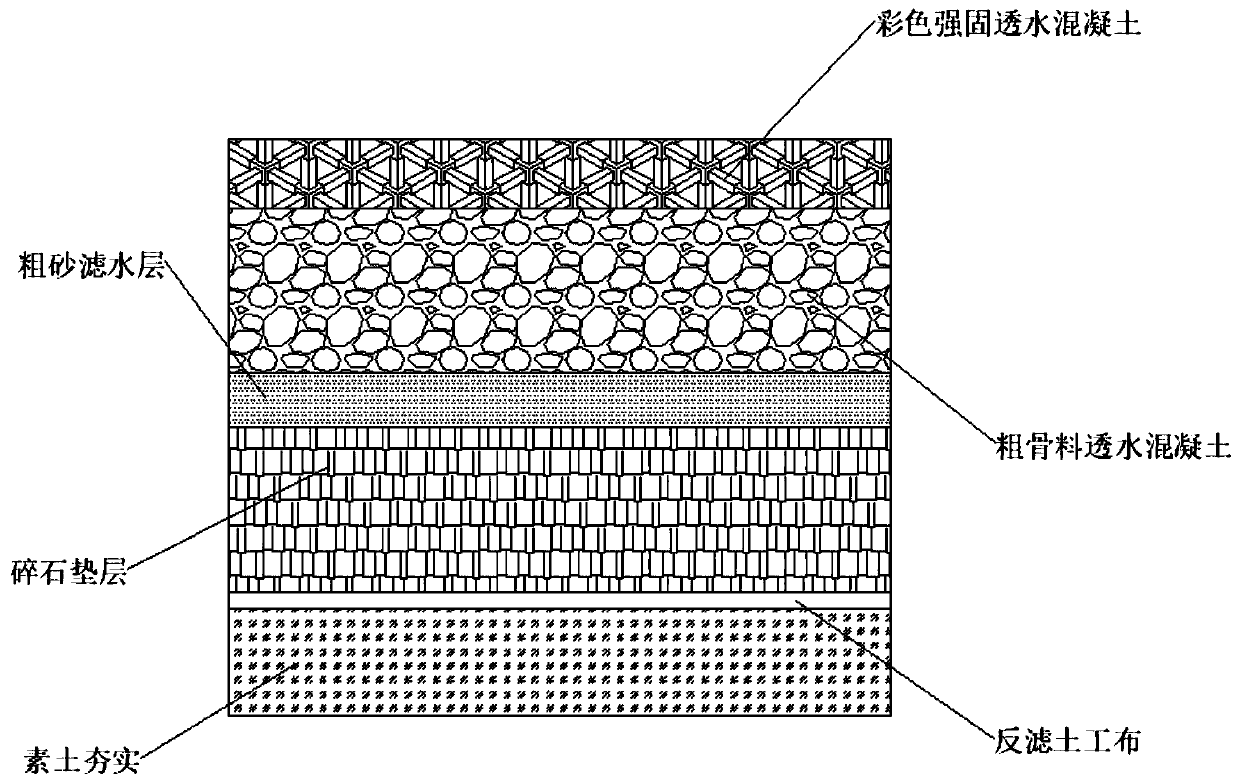

[0030] see figure 2 , the present invention relates to a kind of self-permeable anti-surface water accumulation road concrete, and its preparation method comprises the following steps:

[0031] The first step is to clean the high-fiber plant raw material of 70 parts by weight, then dry it and cut it into a suitable length, then soak it with diammonium hydrogen phosphate solution for 2 hours, and then dry it to complete the pretreatment of the raw material. Among them, the high-fiber plant raw material is selected from one of the plants with high fiber content such as straw, sisal hemp, flax and sugar cane;

[0032] The second step is to carbonize the high-fiber plant raw material obtained in the previous step at a temperature of 900°C in a high-temperature calcination furnace, and pass in an inert gas for protection, and then pass in water vapor for activation for 1 hour, so that the micropore diameter on the raw material gradually Increase the number of micropores, increase...

Embodiment 2

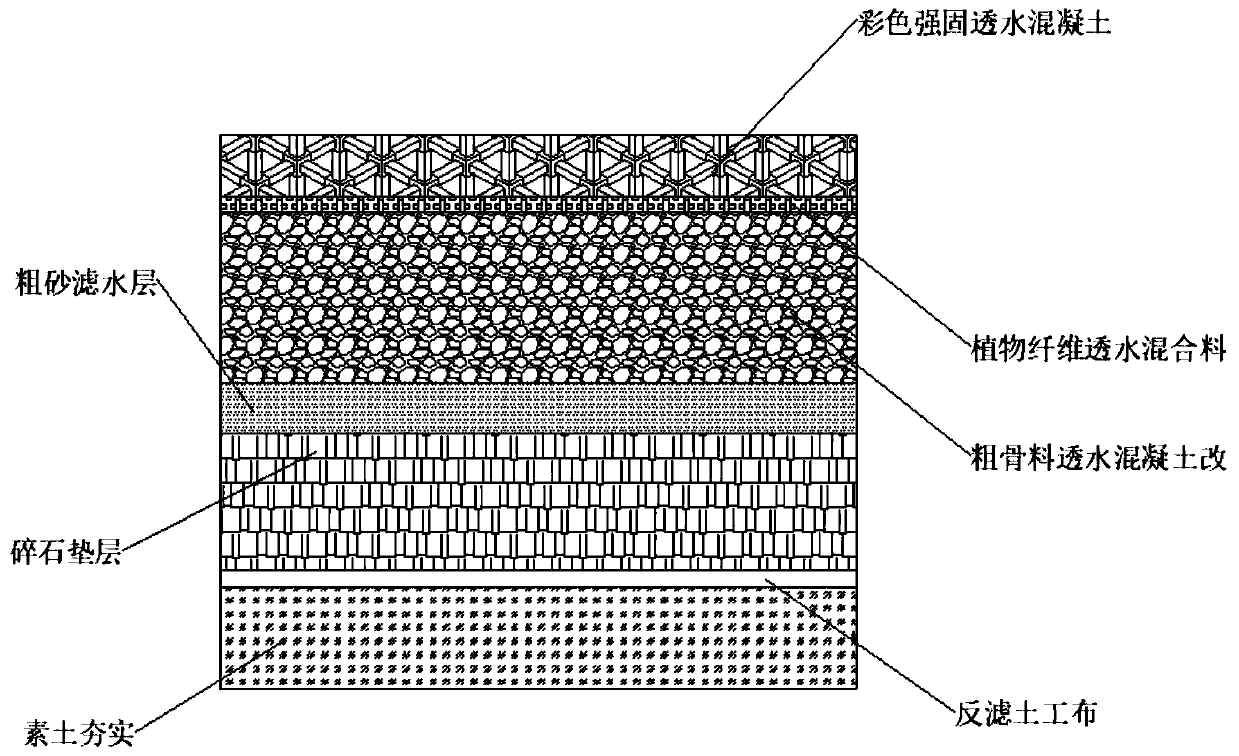

[0038] see figure 2 , the present invention relates to a kind of self-permeable anti-surface water accumulation road concrete, and its preparation method comprises the following steps:

[0039] The first step is to clean the high-fiber plant raw material of 80 parts by weight, then dry it and cut it into a suitable length, then soak it with diammonium hydrogen phosphate solution for 4 hours, and then dry it to complete the pretreatment of the raw material. Among them, the high-fiber plant raw material is selected from one of the plants with high fiber content such as straw, sisal hemp, flax and sugar cane;

[0040]The second step is to carbonize the high-fiber plant raw material obtained in the previous step at a temperature of 1000°C in a high-temperature calcination furnace, and pass in an inert gas for protection, and then pass in water vapor for activation for 1.5 hours, so that the micropore diameter on the raw material gradually Increase the number of micropores, incre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com