A method of connecting alon ceramics with alon powder as a raw material

A technology of powder and ceramics, which is applied in the field of preparation of transparent ceramic materials, can solve the problems that ceramic connections are not easy to implement, and achieve the effects of easy processing, improved interface bonding strength, and improved connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The mixture of pure-phase AlON powder and 0.5wt.% yttrium oxide powder is used as raw material, and sintered at 1880°C for 80 minutes to obtain a transparent AlON ceramic block, which is ground with a diamond particle size of 6-8 μm Finally, it was polished with 0.5 μm diamond polishing paste, then placed in absolute ethanol solution, ultrasonically cleaned for 30 min, and dried.

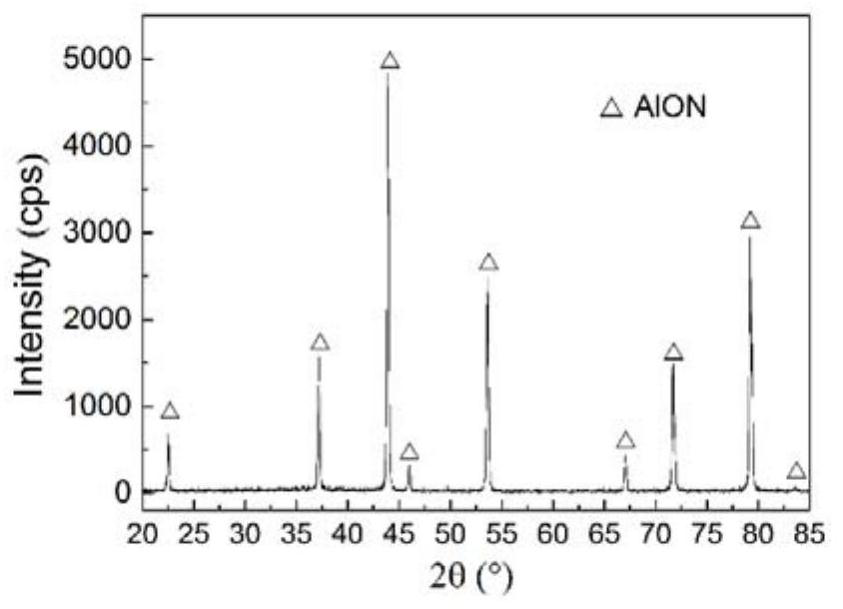

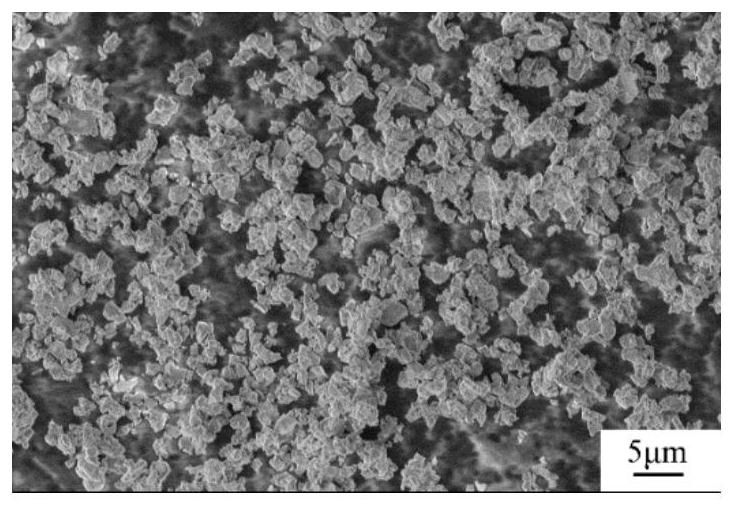

[0043] Use pure phase AlON powder (see attached figure 1 ), adding 0.5wt.% of Y 2 o 3 As a sintering aid, after ball milling figure 2 The mixed powder shown. Using the dry pressing method, the mixed powder of sintering aid and AlON is pressed into a green body with a diameter of 13 mm at 25 MPa, and the green body is placed on the surface of the AlON ceramic to be connected, and another AlON transparent ceramic to be connected is placed on the On top of the green body, the sample is placed in a carbon furnace, and then a graphite block is placed on the sample, so that the pressure applie...

Embodiment 2

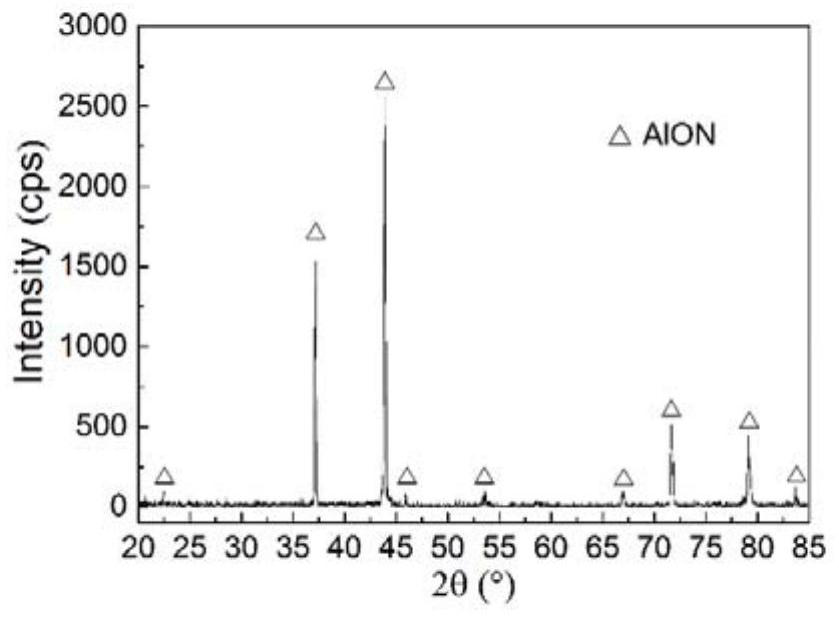

[0046] The difference from Example 1 is that the mixed powder of the sintering aid and AlON is directly placed on the surface of the AlON transparent ceramic to be connected. After connection, the phase composition of the dense interlayer is pure phase AlON (see attached Figure 5 ), at the interface between the intermediate layer and the substrate, grains grow across the interface (see attached Image 6 ). The flexural strength of the sample after connection is 199.4MPa (see attached Figure 7 ), reaching 86% of the AlON matrix strength after connection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com