SiC high-temperature pressure sensor without lead package and manufacturing method thereof

A technology of a pressure sensor and a manufacturing method, which is applied in the field of wide-bandgap semiconductor device preparation, can solve the problems of narrow bandgap width, degradation of mechanical properties of silicon materials, poor high temperature resistance and radiation resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific embodiments of the leadless packaged SiC high-temperature pressure sensor and its manufacturing method involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0051]

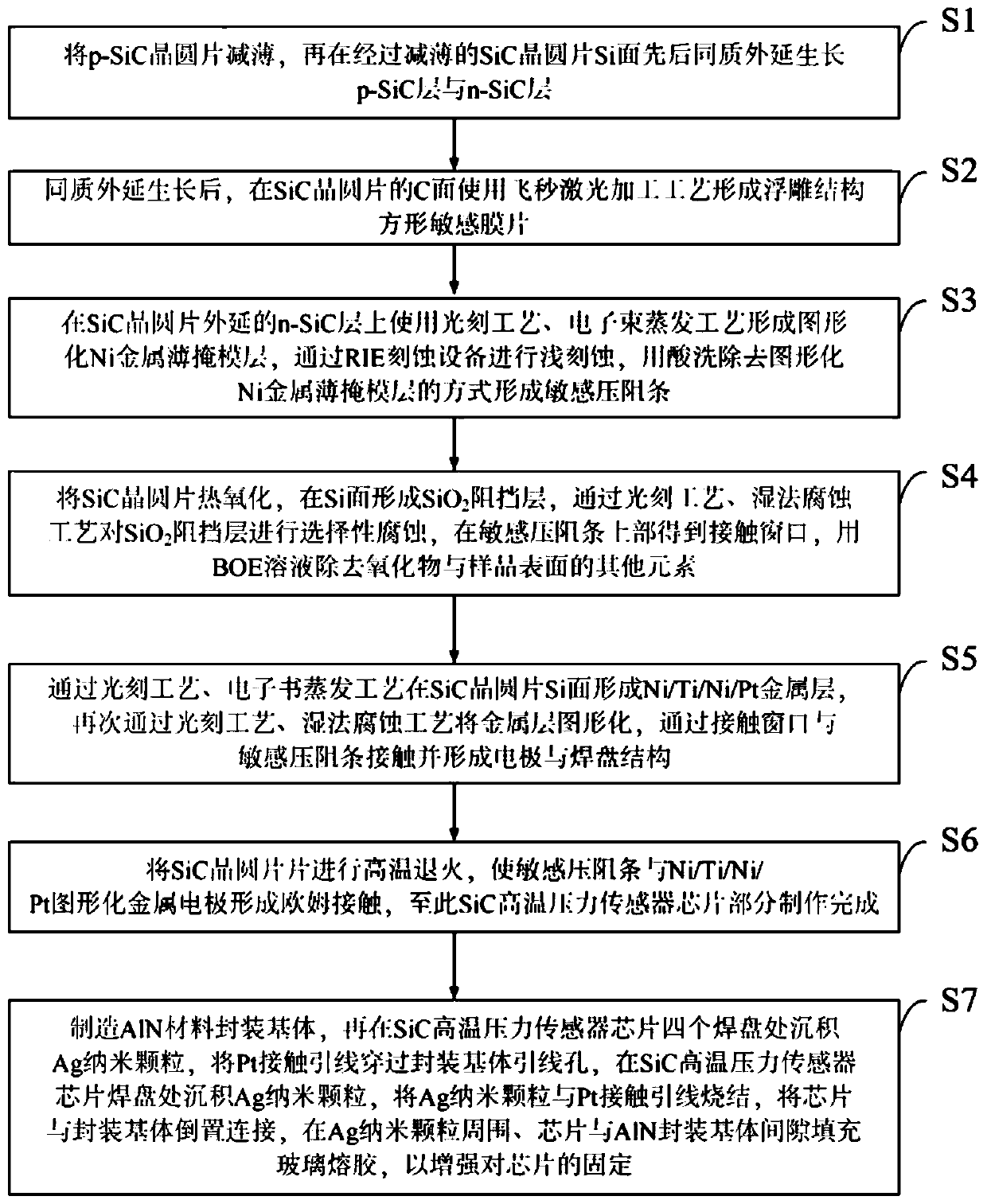

[0052] Such as figure 1 As shown, the method for manufacturing a leadless packaged SiC high-temperature pressure sensor provided in this embodiment includes the following steps:

[0053] (1) if figure 2 and 3 As shown, the p-SiC wafer 100 is thinned to 130 μm, image 3 The dashed line shows the thinned part; as Figure 4 As shown, the Si surface of the thinned SiC wafer 100 is homoepitaxially grown with a thickness of 5 μm and a doping concentration of 3×10 18 cm -3(±15%) p-SiC layer 101, the growth thickness is 2 μm, and the doping concentration is 1×10 19 cm -3 (±15%) n-SiC layer 102 .

[0054] (2) if Figure 5-7 As shown, a square sensitive diaphragm 103 with a relief structure is formed on the C surface of the p-SiC wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com