Air-exhaust-type wind-sand flow gradient high sand-collecting rate device for wind-sand environment wind tunnel

A kind of wind sand flow and gradient technology, which can be used in measurement devices, aerodynamic tests, instruments, etc., can solve problems such as errors in the amount of sediment transport, and achieve the effect of overcoming the loss of fine sand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below, the technical scheme of the present invention will be further described in conjunction with the accompanying drawings:

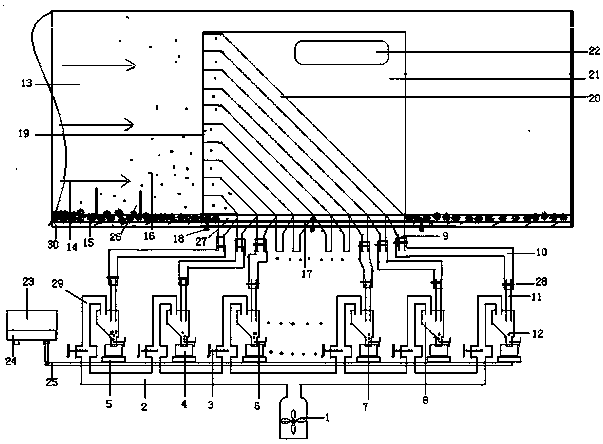

[0012] Such as figure 1 As shown, a wind-sand environment wind tunnel pumping type wind-sand flow gradient high sand collection rate device is mainly composed of an air pump 1, a weighing bottle 4, a high-precision weighing sensor 5, a wind-sand flow separation tank 8, a gradient leak nozzle 9, Wind and sand environment wind tunnel 13, sand bed surface 15, gradient channel 20, sand and dust gradient collector 21, paperless multi-channel recorder 23, multi-channel sensor bridge circuit 24, and test sand barrier model 26. In the sandstorm environment wind tunnel 13, 10 collector placement openings 27 tighten the fixed side plates 17 on both sides with screws and nuts 18. Before laying the sand, the placement port 27 of the sand and dust gradient collector is covered with a plate to prevent the loss of the sand laid on the bed surface, and the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com