Rosin-based wood modifier, and preparation method and application thereof

A modifier, rosin-based technology, applied in wood treatment, wood heating, impregnation of wood, etc., can solve the problems of easy loss, limited application, low melting point of rosin, etc., achieve simple preparation method and treatment process, good dimensional stability , Overcome the effect of easy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method and application of a rosin-based wood modifier, comprising the steps of:

[0032] 1) Dissolving rosin in toluene, adding glycidyl methacrylate, acid-binding agent and hydroquinone, and reacting at 120° C. for 7 hours under the protection of nitrogen. The molar ratio of rosin to glycidyl methacrylate is 1:1.

[0033] 2) The reaction product was cooled to room temperature, washed with water three times, dried and then evaporated to remove the solvent to obtain rosin-based acrylate.

[0034] 3) Dissolving rosin acrylate in pyridine, adding 1% azobisisobutyronitrile to prepare a 15% rosin-based wood modifier.

[0035] 4) Soak the poplar wood specimen in the modifier, impregnate the specimen under 0.08MPa vacuum condition for 30 minutes, then impregnate it under normal pressure for 10 hours, take out the specimen and bake it at 120°C for 10 hours, and extract it in ethanol for 6 hours , and finally baked to absolute dryness at 103°C.

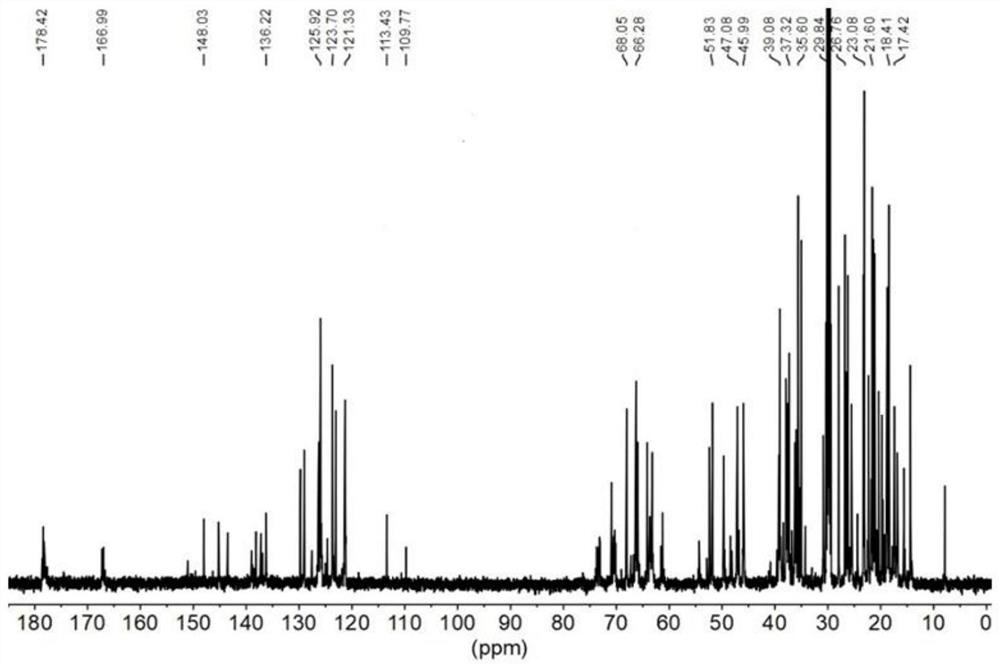

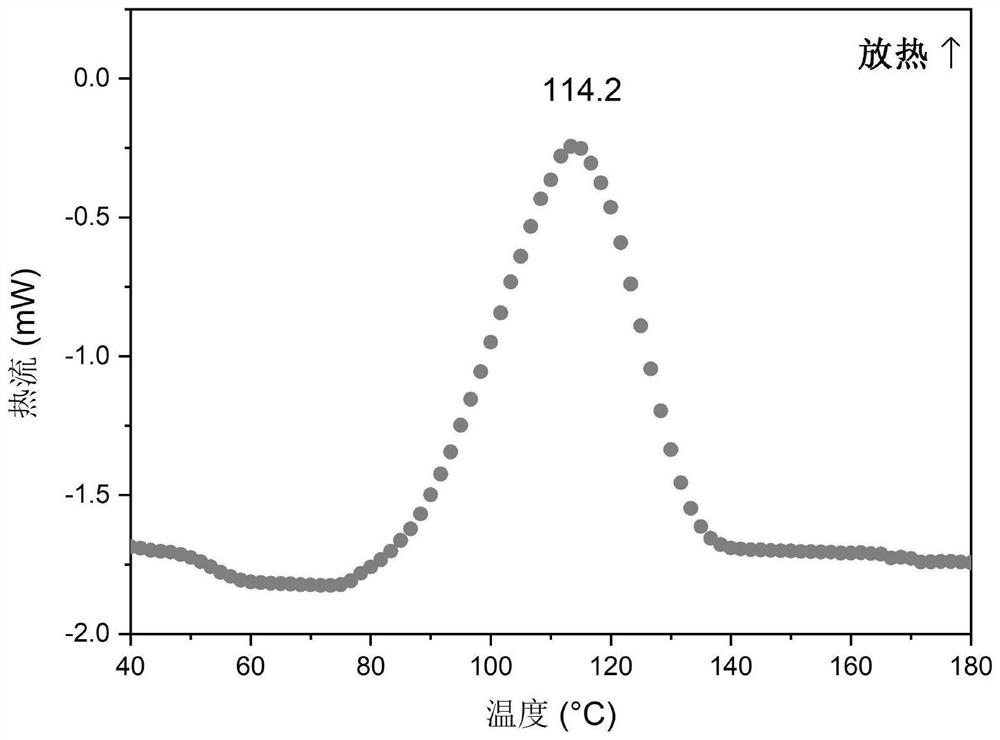

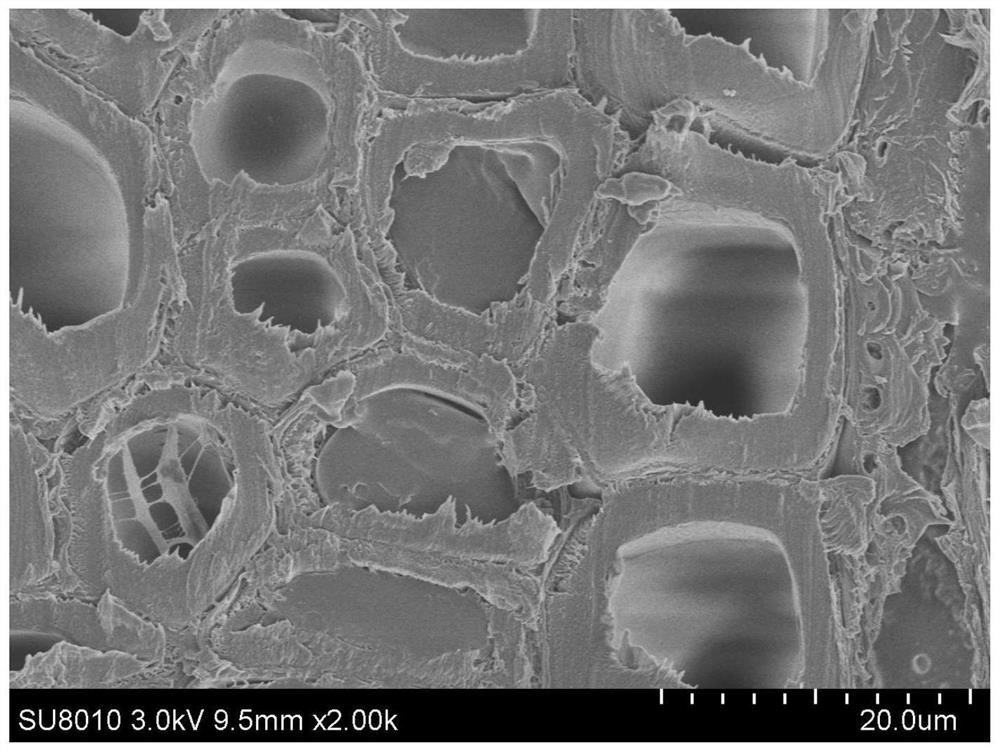

[0036] The chem...

Embodiment 2

[0039] The preparation method of rosin-based acrylate is the same as in Example 1.

[0040] Subsequently, rosin acrylate was dissolved in pyridine, and 1% azobisisobutyronitrile was added to prepare a 30% rosin-based wood modifier.

[0041] Soak the poplar wood specimen in the modifier, immerse the specimen under 0.08MPa vacuum condition for 30 minutes, then impregnate it under normal pressure for 10 hours, take out the specimen and bake it at 120°C for 10 hours, extract it in ethanol for 6 hours, and finally Dry to dryness at 103°C.

Embodiment 3

[0043] A preparation method and application of a rosin-based wood modifier, comprising the steps of:

[0044] 1) Dissolving rosin in toluene, adding glycidyl methacrylate, acid-binding agent and hydroquinone, and reacting at 120° C. for 7 hours under the protection of nitrogen. The molar ratio of rosin to glycidyl methacrylate is 1:2.

[0045] 2) The reaction product was cooled to room temperature, washed with water three times, dried and then evaporated to remove the solvent to obtain rosin-based acrylate.

[0046] 3) Dissolving rosin acrylate in pyridine, adding 1% azobisisobutyronitrile to prepare a 15% rosin-based wood modifier.

[0047] 4) Soak the poplar wood specimen in the modifier, immerse the specimen under 0.08MPa vacuum condition for 30 minutes, then impregnate it under normal pressure for 10 hours, take out the specimen and bake it at 120°C for 10 hours, and extract it in ethanol for 6 hours. Finally, it was dried to absolute dryness at 103°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com