High-strength dental composite resin and preparation method thereof

A composite resin and dental technology, used in dental preparations, dentistry, dental prostheses, etc., can solve the problems of low content of mesoporous fillers, time-consuming and laborious, and unfavorable industrial production, and achieve the effect of increasing the total content and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

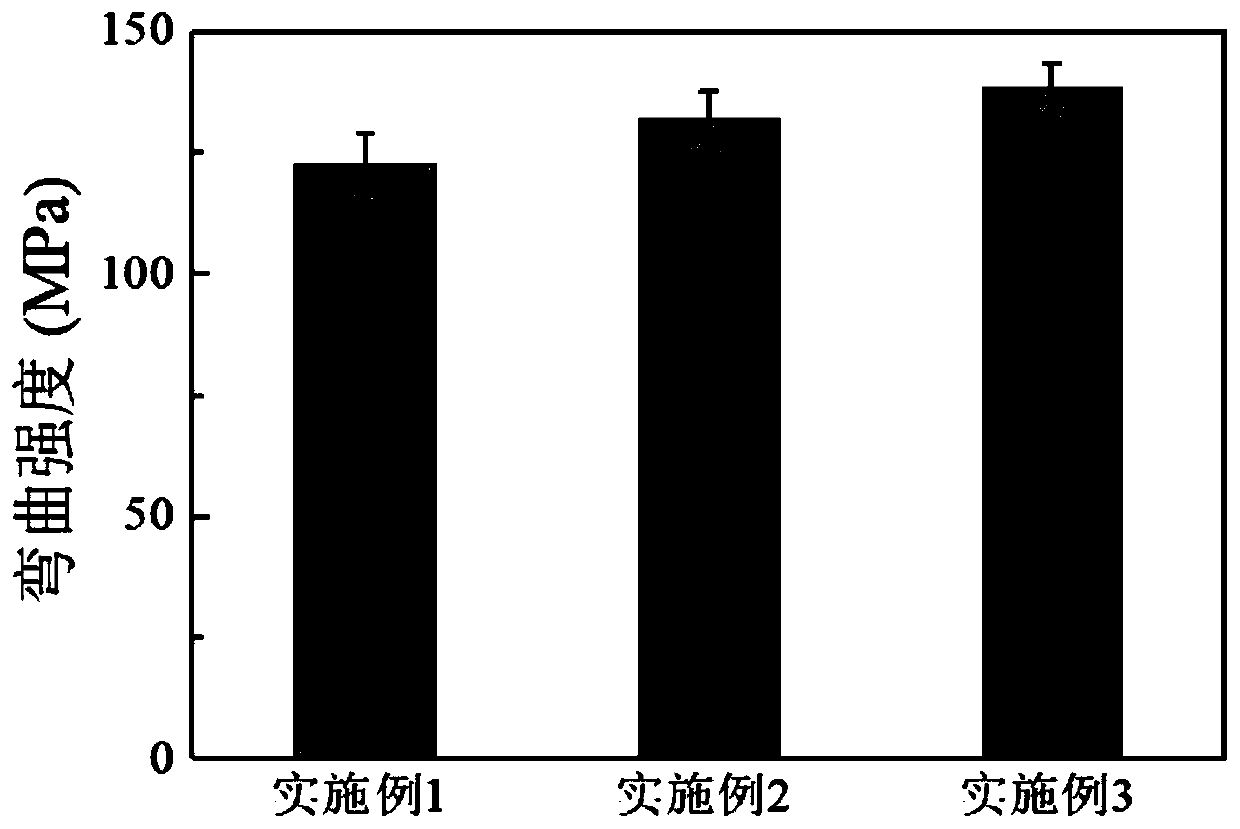

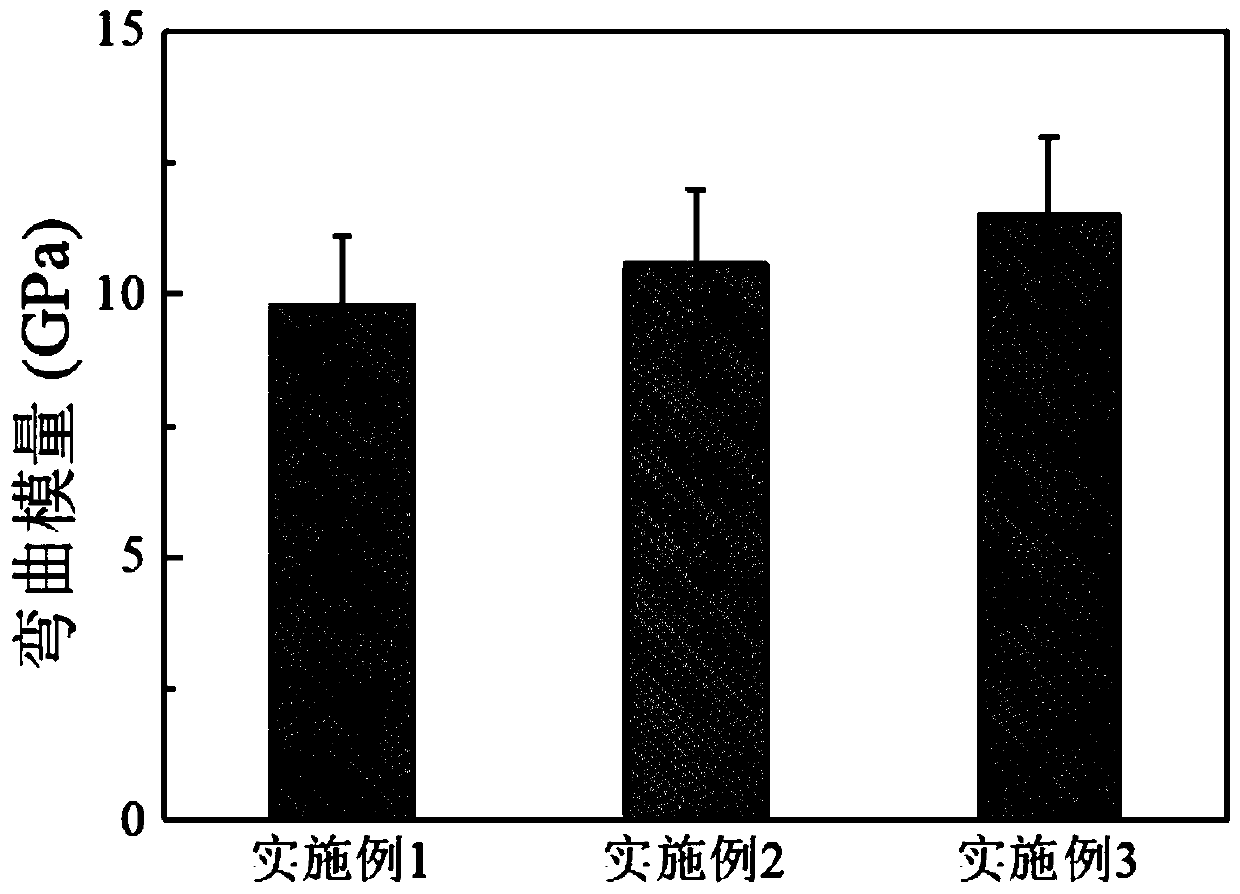

Embodiment 1

[0025] (1) Composition of inorganic fillers

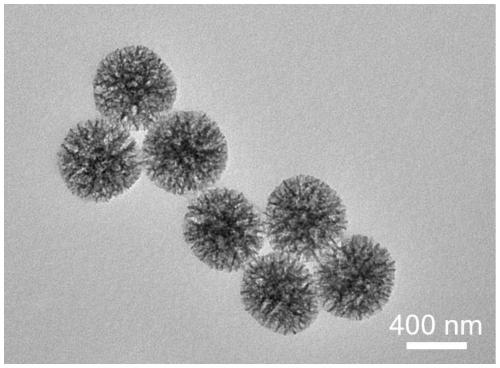

[0026] According to the close-packing model of equal-sized spheres, the formulas for calculating the maximum diameters of spherical particles that can fill the octahedral voids and tetrahedral voids of equal-sized spheres (primary particles) are d 8 = 0.828R and d 4 =0.45R (R is the radius of the equal sphere). Spherical mesoporous silica with a particle diameter of 550nm was selected as the primary particle, and spherical silica with a particle diameter of 227nm and 123nm were respectively selected as the secondary particle according to the calculation results.

[0027] (2) Preparation of composite resin

[0028] According to the formula shown in Table 1, the spherical mesoporous silica with a particle size of 550nm, the organic monomer and the photoinitiator are mixed first by manual premixing. When the filler is fully wetted by the resin matrix, put it into three rollers. Grinder (EXAKT80E, Germany) for secondary mixing. Sec...

Embodiment 2

[0034] (1) Composition of inorganic fillers

[0035] Spherical mesoporous zinc oxide with a particle size of 900nm was selected as the primary particle, and spherical titanium dioxide with a particle size of 372nm and 202nm was selected as the secondary particle according to the formula shown in Example 1.

[0036] (2) Preparation of composite resin

[0037] According to the formula shown in Table 2, firstly, the spherical mesoporous zinc oxide with a particle size of 900nm, organic monomer and photoinitiator were mixed by manual premixing. When the filler was fully wetted by the resin matrix, it was put into three-roll grinding Machine (EXAKT 80E, Germany) secondary mixing. Secondly, after adding spherical titanium dioxide with a particle diameter of 372nm to the maximum addition amount, then adding spherical titanium dioxide with a particle diameter of 202nm to the maximum addition amount. After vacuum negative pressure treatment, an uncured composite resin paste is obtain...

Embodiment 3

[0043] (1) Composition of inorganic fillers

[0044] Spherical mesoporous silica with a particle size of 1.2 μm was selected as the primary particle, and spherical hydroxyapatite with a particle size of 496 nm and 270 nm were respectively selected as the secondary particle according to the formula shown in Example 1.

[0045] (2) Preparation of composite resin

[0046] According to the formula shown in Table 3, the spherical mesoporous silica with a particle size of 1.2 μm, the organic monomer and the photoinitiator were mixed first by manual premixing. When the filler was fully wetted by the resin matrix, three Roll mill (EXAKT80E, Germany) secondary mixing. Secondly, after adding spherical hydroxyapatite with a particle diameter of 496nm to the maximum addition amount, then adding spherical hydroxyapatite with a particle diameter of 270nm to the maximum addition amount. After vacuum negative pressure treatment, an uncured composite resin paste is obtained. Subsequent curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com