VOCs (volatile organic compounds) gas recycling apparatus

A processing device and gas recovery technology, applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of serious, increased environmental pollution, lack of hydrocarbon gas recovery technology, etc., to achieve the reduction of VOCs content, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make those skilled in the art more clearly understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

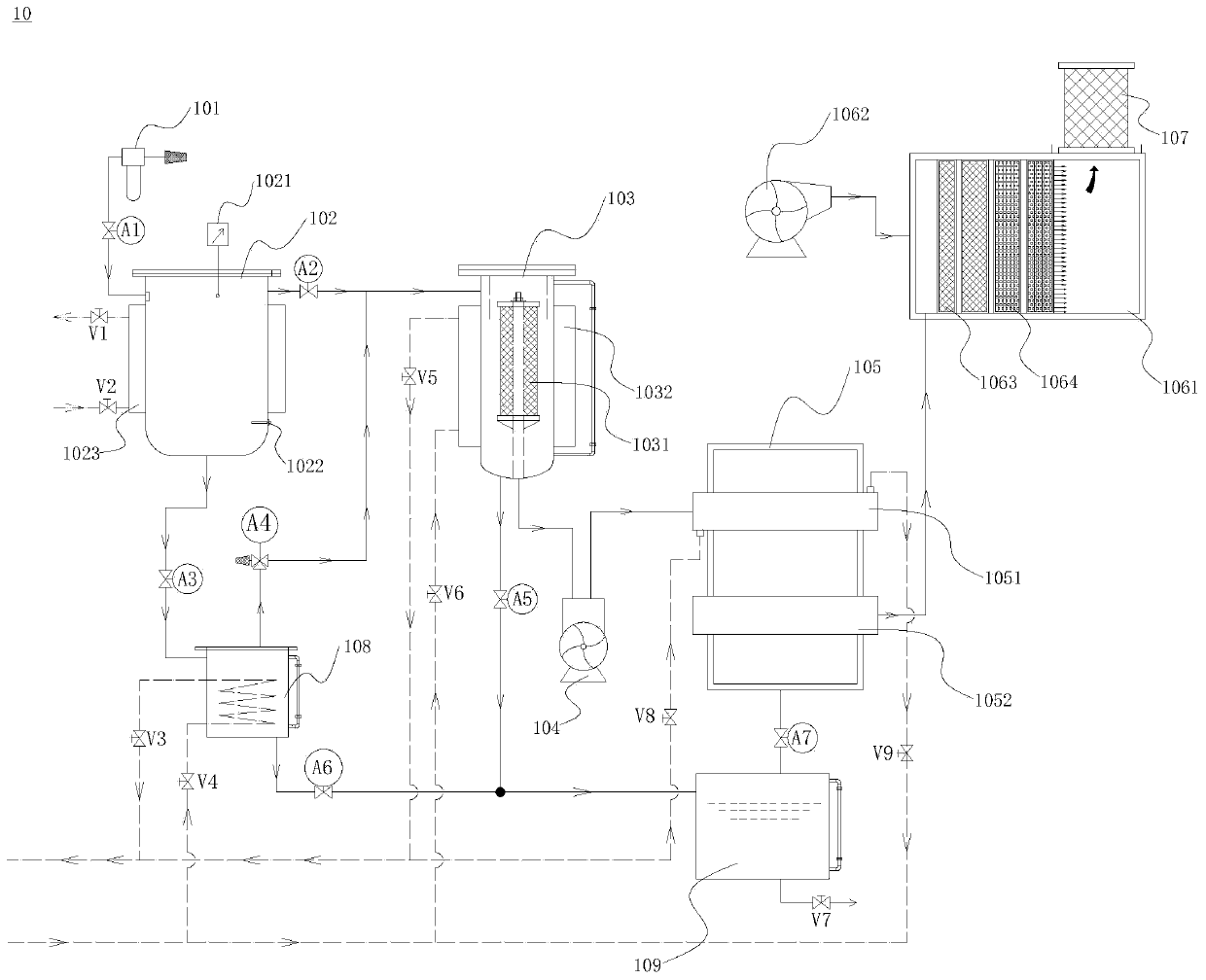

[0023] refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the VOCs gas recovery treatment device 10 of the present invention. In the embodiment shown in the drawings, the recovery treatment device 10 includes a second filter 101, a drying tank 102, a gas-liquid separator 103, a vacuum pump 104, a refrigeration mechanism 105 and a filter discharge device connected by pipelines. Wherein the second filter 101 gas outlet is connected with the drying tank 102 inlet to filter the impurities in the VOCs gas after cleaning, and the pipeline connecting the two is provided with a solenoid valve A1 for controlling the gas flow; The outer wall of the drying tank 102 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com