Utilizing system for coal washing circulating water

A technology of circulating water and coal washing, which is applied in the field of water circulation system, can solve the problems of waste and waste of water resources, and achieve the effects of avoiding waste, reducing waste, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

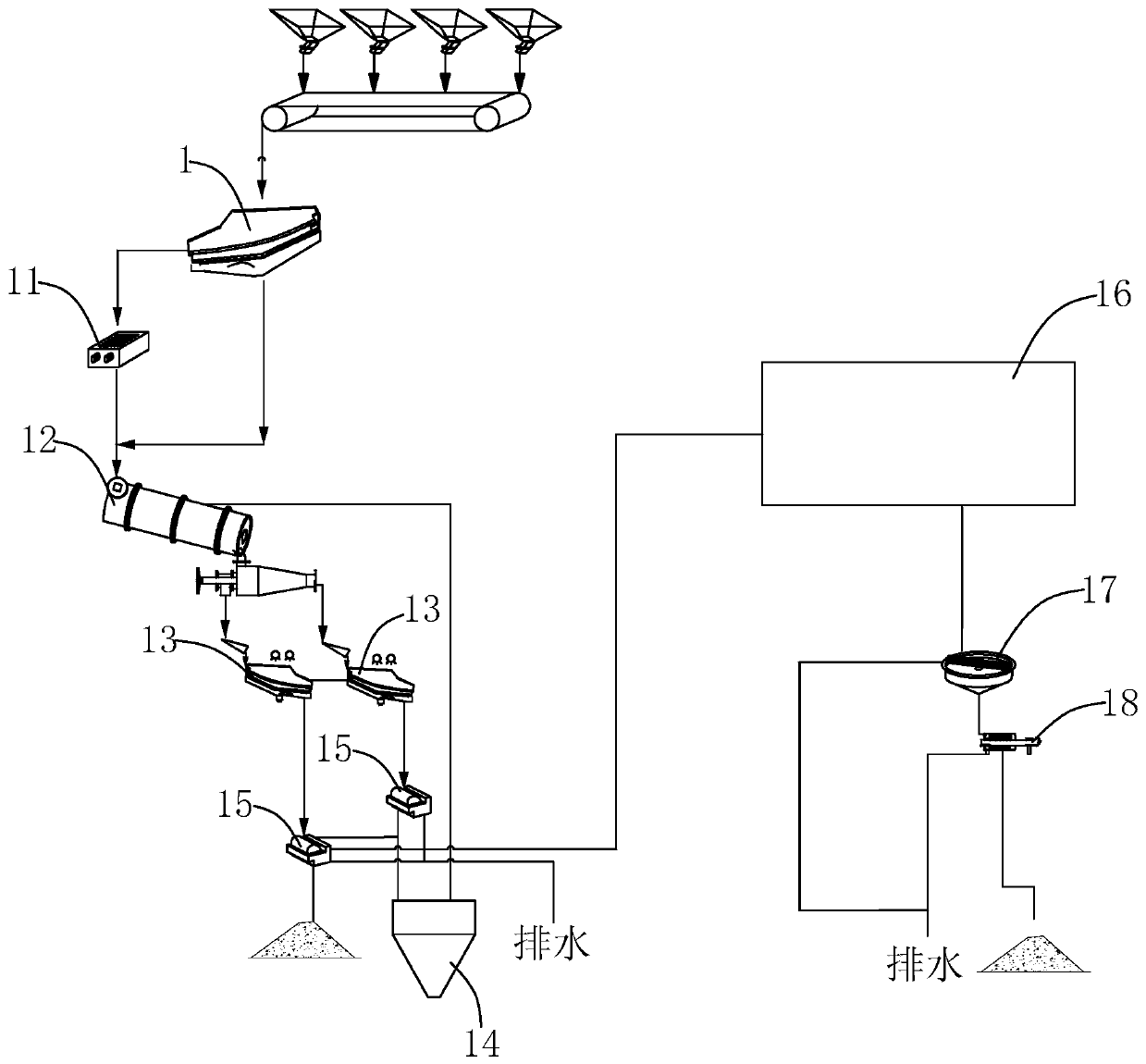

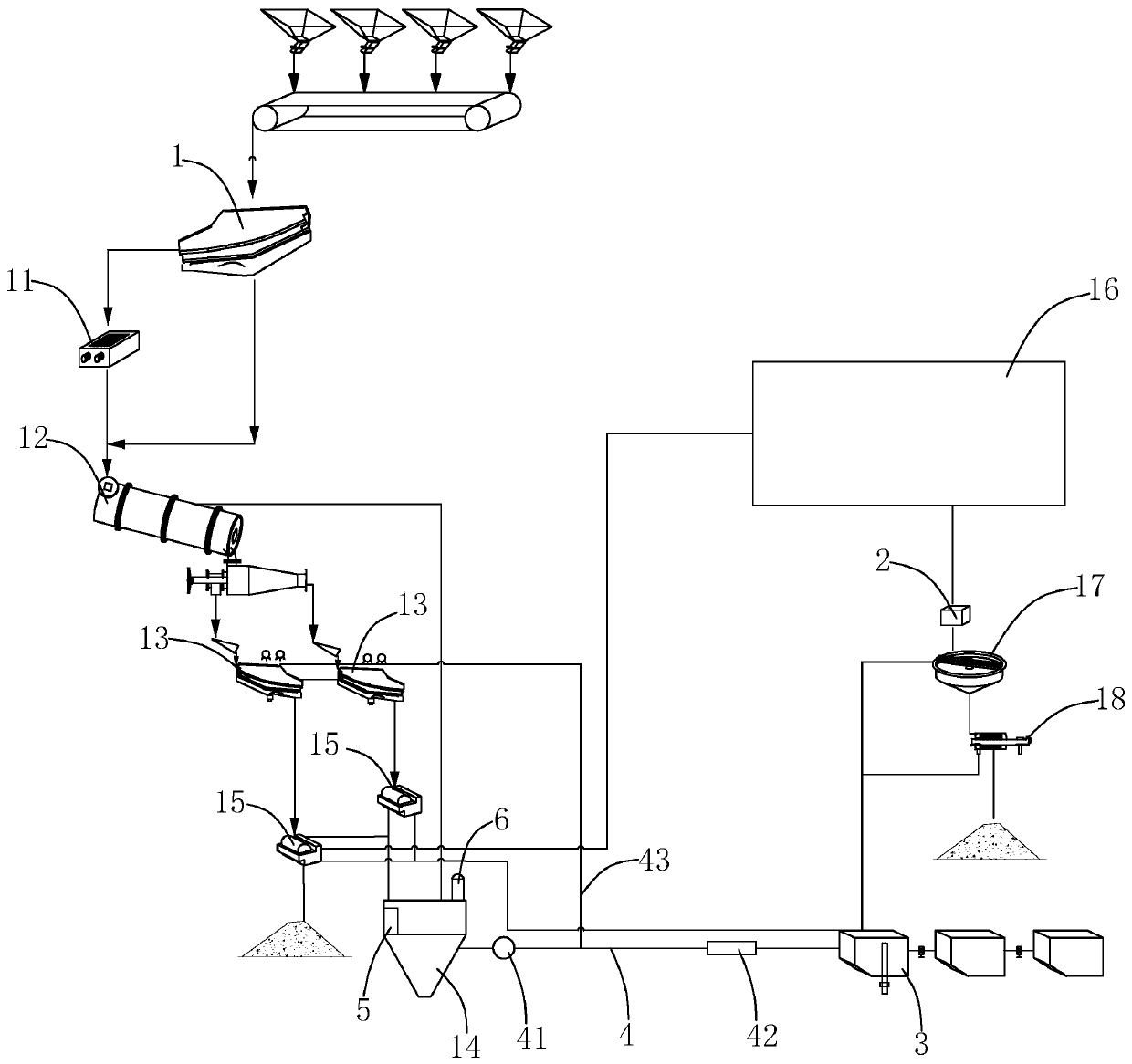

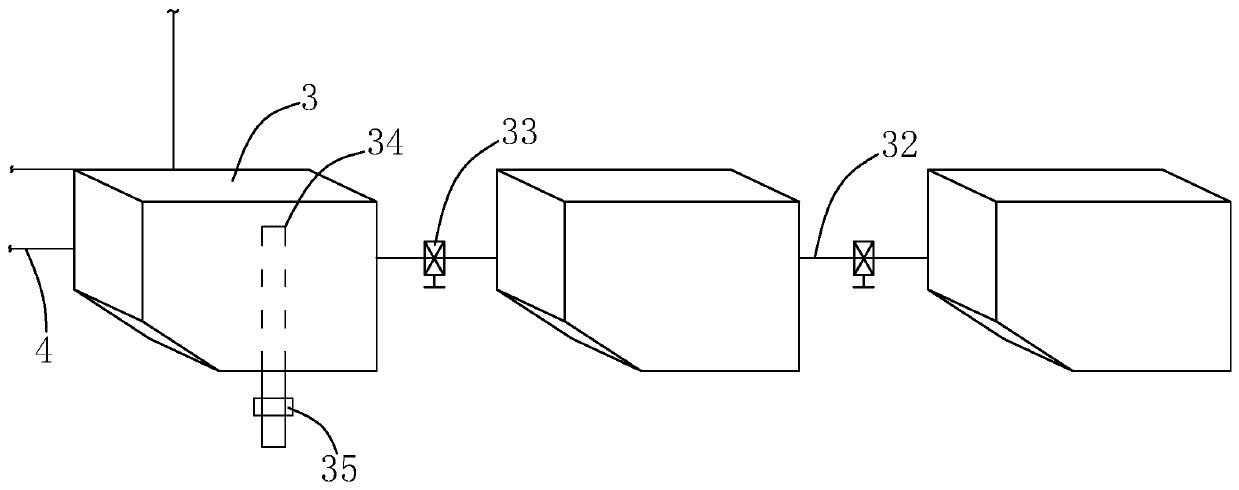

[0035] refer to figure 2 , is a coal washing circulating water utilization system disclosed in the present invention, including a buffer tank 2, a sedimentation tank 17 connected to the buffer tank 2, and a water tank 3 for collecting detached water, wherein the upper water in the sedimentation tank 17 passes through The way of overflow is transported to the pool 3, thereby preventing the flotation tailings from being lost together with the water. After the flotation treatment, the flotation tailings are first passed into the buffer tank 2 for buffering, and then enter the sedimentation tank 17 for sedimentation, so as to prevent the flotation tailings from directly passing into the sedimentation tank 17 from causing the original static The flotation tailings become chaotic again, affecting the effect and efficiency of sedimentation. The water after dehydration and deintermediation is respectively connected with the pool 3 through pipelines, and finally collects in the pool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com