Gasifying grey water hardness-removing turbidity-lowering device and process method

A grey water and turbidity reduction technology, applied in chemical instruments and methods, natural water treatment, water/sewage multi-stage treatment, etc., can solve the problems of difficult cleaning work, increased operating costs, and increased difficulty in terminal sewage treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

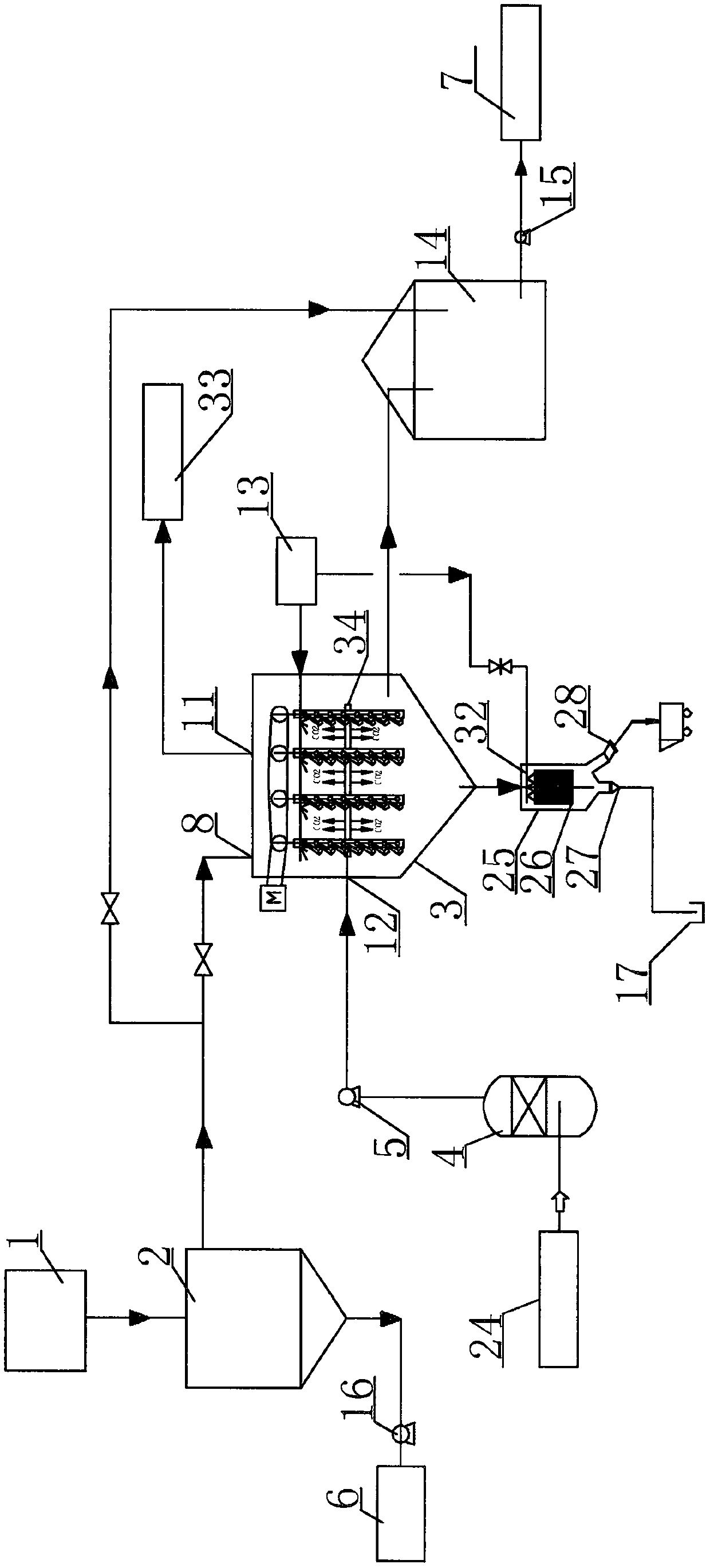

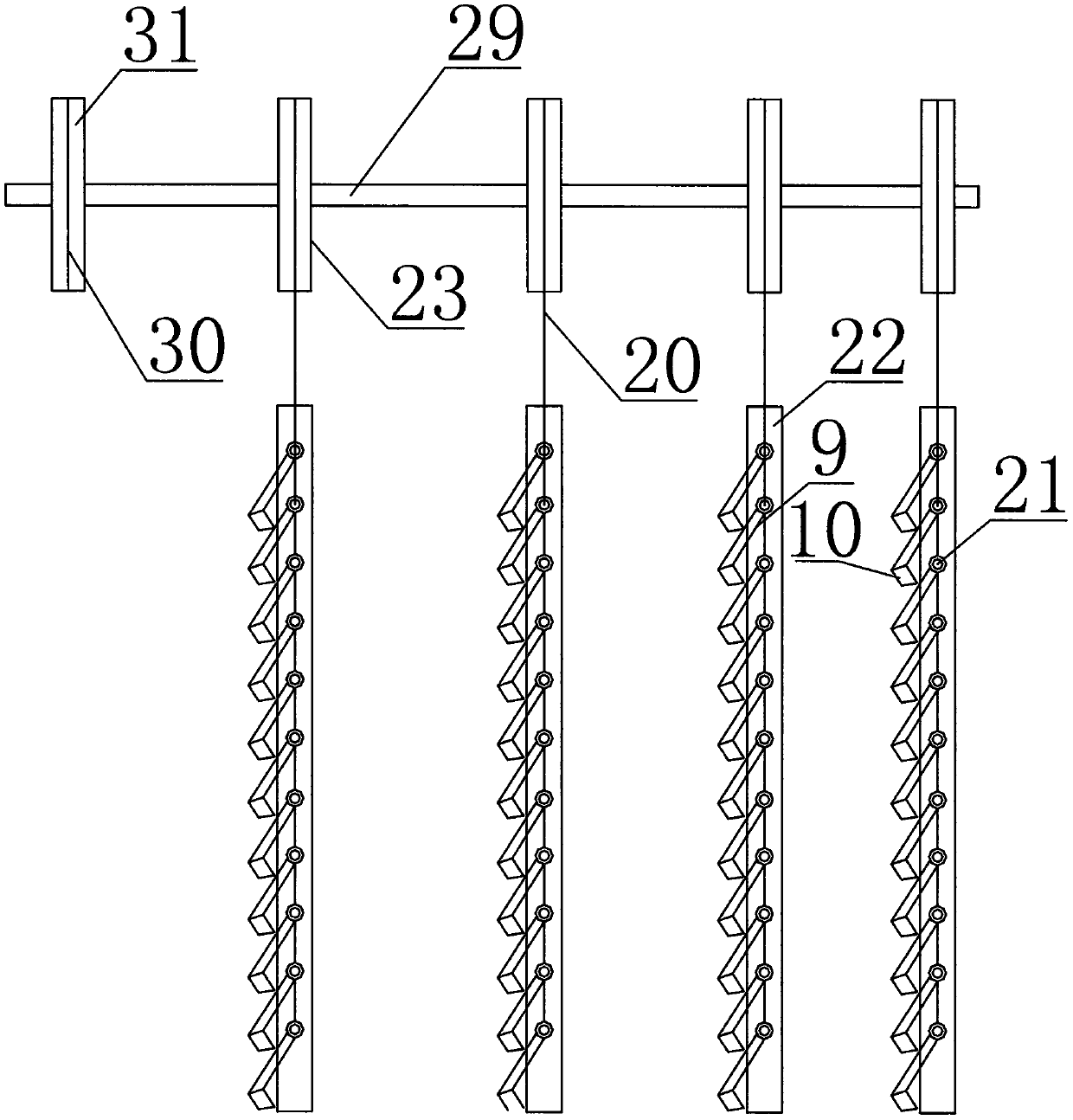

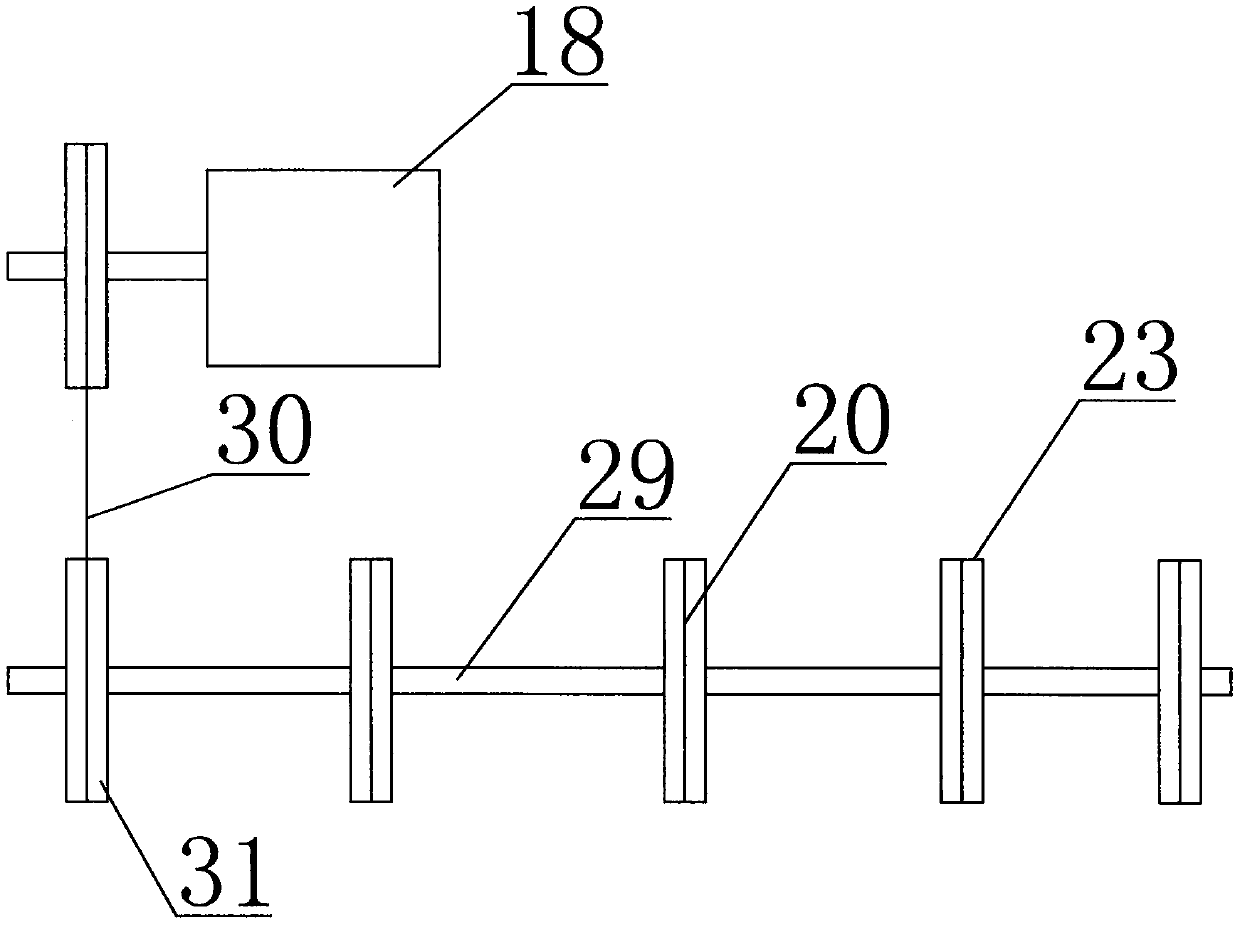

[0056] A device for removing hardness and reducing turbidity of gasified gray water, comprising a three-stage flash system 1, the three-stage flash system 1 is connected to a clarifier 2 through a gray water pipeline, and the slurry outlet at the bottom of the clarifier 2 is connected to a discharge pump 16 and The vacuum filter press 6 is connected, and the outlet of the supernatant on the top of the clarification tank 2 is connected to the inlet of the gray water tank 14 through a tee, and the outlet of the gray water tank 14 is connected to the standby section 7 through the gray water pump 15, and the outlet of the three-way The third end links to each other with the inlet of the gray water tank 14 through the gray water dehardening self-cleaning unit; the gray water dehardening self-cleaning unit comprises the gray water dehardening self-cleaning housing 3, and the top of the gray water dehardening self-cleaning housing 3 There is an acid gas outlet 11 and a gray water inle...

Embodiment 2

[0072]A device for removing hardness and reducing turbidity of gasified gray water, comprising a three-stage flash system 1, the three-stage flash system 1 is connected to a clarifier 2 through a gray water pipeline, and the slurry outlet at the bottom of the clarifier 2 is connected to a discharge pump 16 and The vacuum filter press 6 is connected, and the outlet of the supernatant on the top of the clarification tank 2 is connected to the inlet of the gray water tank 14 through a tee, and the outlet of the gray water tank 14 is connected to the standby section 7 through the gray water pump 15, and the outlet of the three-way The third end links to each other with the inlet of the gray water tank 14 through the gray water dehardening self-cleaning unit; the gray water dehardening self-cleaning unit comprises the gray water dehardening self-cleaning housing 3, and the top of the gray water dehardening self-cleaning housing 3 There is an acid gas outlet 11 and a gray water inlet...

Embodiment 3

[0088] A device for removing hardness and reducing turbidity of gasified gray water, comprising a three-stage flash system 1, the three-stage flash system 1 is connected to a clarifier 2 through a gray water pipeline, and the slurry outlet at the bottom of the clarifier 2 is connected to a discharge pump 16 and The vacuum filter press 6 is connected, and the outlet of the supernatant on the top of the clarification tank 2 is connected to the inlet of the gray water tank 14 through a tee, and the outlet of the gray water tank 14 is connected to the standby section 7 through the gray water pump 15, and the outlet of the three-way The third end links to each other with the inlet of the gray water tank 14 through the gray water dehardening self-cleaning unit; the gray water dehardening self-cleaning unit comprises the gray water dehardening self-cleaning housing 3, and the top of the gray water dehardening self-cleaning housing 3 There is an acid gas outlet 11 and a gray water inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com