Method of nano-modifying flame-retardant ethylene-vinyl acetate copolymer via two-dimensional material

A vinyl acetate, two-dimensional material technology, applied in the field of flame retardant materials, can solve the problems of poor flame retardant effect, uneven dispersion of two-dimensional materials, etc., to improve the flame retardant efficiency, enhance the synergistic effect, and improve the flame retardant performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for nano-modified flame-retardant ethylene-vinyl acetate copolymer of a two-dimensional material, each component and its mass percentage content are shown in the following table: (based on the total mass percentage as 100%)

[0048]

[0049]

[0050] Specific steps are as follows:

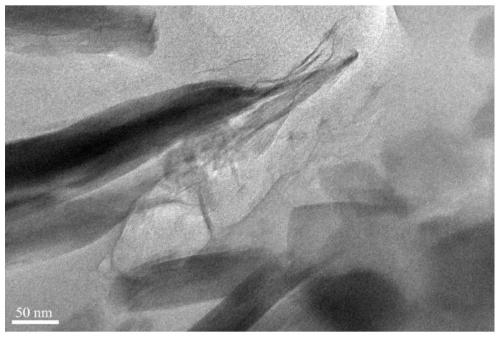

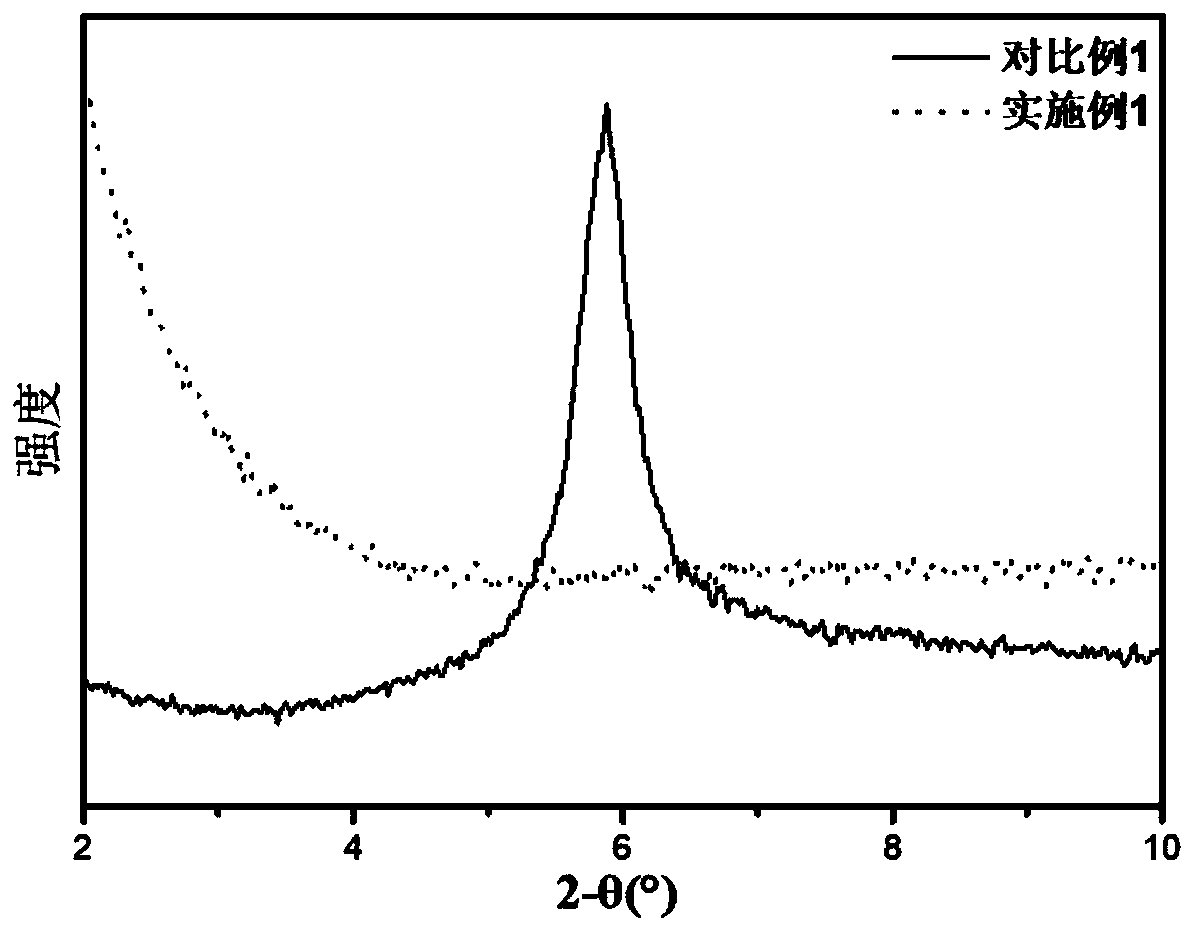

[0051] (1) After aluminum hydroxide and montmorillonite are dried in an oven at 80°C, they are mixed at a ratio of 10:1 and put into a zirconia ball milling jar, and then zirconia ball milling beads are put into the ball milling jar, and the powder and ball milling beads Total mass is 800g, setting ball mill rotating speed 800rpm, ball milling 2h, obtains a kind of nanocomposite fire retardant that montmorillonite is exfoliated and dispersed in aluminum hydroxide, and its transmission electron microscope is as follows: Figure 6 As shown in the figure, it can be seen that the montmorillonite is delaminated and peeled off, and it is evenly mixed with the aluminum hydroxide part...

Embodiment 2

[0056] Taking the total mass of the composite material as 100%, the components and mass percentages are as follows:

[0057]

[0058]

[0059] Specific steps are as follows:

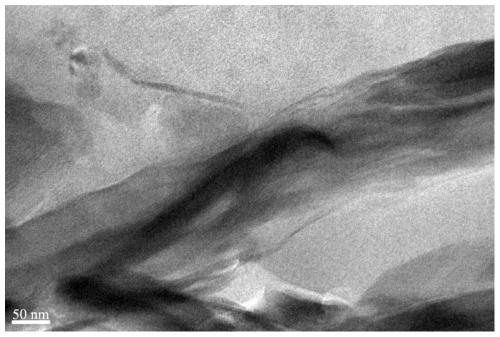

[0060] (1) After drying melamine cyanurate and montmorillonite in an oven at 80°C, mix them at a ratio of 4:1 and put them into a zirconia ball milling jar, then put the zirconia ball milling beads into the ball milling jar, the powder and The total mass of ball milling beads is 300g, the ball mill speed is set at 800rpm, and ball milling is carried out for 3h to obtain a nanocomposite flame retardant that is exfoliated from montmorillonite and dispersed in melamine cyanurate. Its transmission electron microscope is as follows: Figure 7 As shown in the figure, it can be seen that the montmorillonite is delaminated and peeled off, and it is evenly mixed with the aluminum hydroxide particles.

[0061] (2) The ethylene-vinyl acetate copolymer, compatibilizer, montmorillonite exfoliated and dispersed...

Embodiment 3

[0065] Taking the total mass of the composite material as 100%, the components and mass percentages are as follows:

[0066]

[0067]

[0068] Specific steps are as follows:

[0069] (1) After drying hydromagnesite and hydrotalcite in an oven at 80°C, mix them at a ratio of 11:1 and put them into a zirconia ball milling jar, then put zirconia ball milling beads into the ball milling jar, the powder and ball milling beads The total mass is 800g, the rotational speed of the ball mill is set at 800rpm, and the ball mill is milled for 1 hour to obtain a nanocomposite flame retardant in which hydrotalcite is exfoliated and dispersed in hydromagnesite.

[0070] (2) The ethylene-vinyl acetate copolymer, compatibilizer, and hydrotalcite are exfoliated and dispersed in hydromagnesite. The nanocomposite flame retardant and processing aid are first dried in an oven at 80°C, and then they are Put it in a high mixer and mix evenly, send the mixed raw materials into the feeder of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The peak | aaaaa | aaaaa |

| The peak | aaaaa | aaaaa |

| The peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com