Plastic-steel door and window section bar with excellent mechanical properties and method for preparing plastic-steel door and window section bar

A technology for plastic-steel doors and windows and profiles, applied in the field of doors and windows, can solve the problems of poor compatibility between inorganic fillers and PVC systems, poor toughness of plastic-steel door and window profiles, and reduced impact strength, so as to reduce thermal conductivity and moisture permeability. The effect of excellent mechanical properties and high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

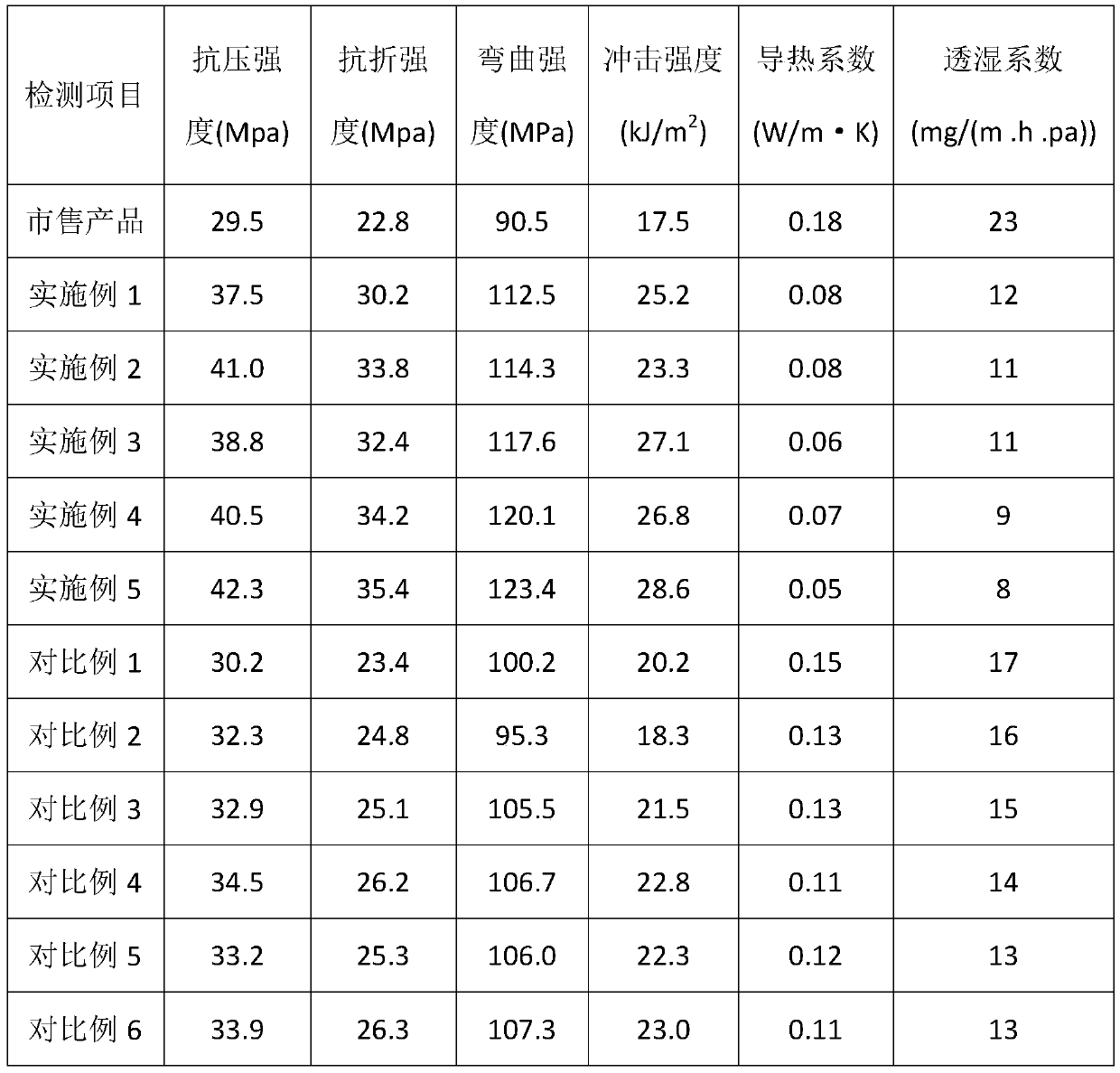

Examples

Embodiment 1

[0023] A plastic-steel door and window profile with excellent mechanical properties provided in this embodiment is based on polyvinyl chloride, and its raw materials include the following components by weight: 25 kg of polyvinyl chloride, 10 kg of acrylonitrile-styrene copolymer, polystyrene And imidazole 5kg, microcrystalline paraffin 1kg, modified alkali-free glass fiber 4kg, modified Lycra fiber 2.5kg.

[0024] Wherein, the modified alkali-free glass fiber is alkali-free glass fiber double-modified by nano-titanium dioxide and potassium permanganate, and its specific modification method is: first soak the alkali-free glass fiber in high manganese In the potassium permanganate solution, the mass of the alkali-free glass fiber soaked in it is 10% of the mass of the potassium permanganate solution, and then the soaked alkali-free glass fiber is dried, and the nano-titanium dioxide is adsorbed on its surface by electrostatic adsorption technology , wherein the adsorption mass o...

Embodiment 2

[0031] A plastic-steel door and window profile with excellent mechanical properties provided by this embodiment is based on polyvinyl chloride, and its raw materials include the following components by weight: 15 kg of polyvinyl chloride, 20 kg of acrylonitrile-styrene copolymer, polystyrene And imidazole 10kg, microcrystalline paraffin 4kg, modified alkali-free glass fiber 7.5kg, modified Lycra fiber 6kg.

[0032] Wherein, the modified alkali-free glass fiber is alkali-free glass fiber double-modified by nano-titanium dioxide and potassium permanganate, and its specific modification method is: first soak the alkali-free glass fiber in high manganese In the potassium permanganate solution, the mass of the alkali-free glass fiber soaked in it is 10% of the mass of the potassium permanganate solution, and then the soaked alkali-free glass fiber is dried, and the nano-titanium dioxide is adsorbed on its surface by electrostatic adsorption technology , wherein the adsorption mass ...

Embodiment 3

[0039] A plastic-steel door and window profile with excellent mechanical properties provided in this embodiment is based on polyvinyl chloride, and its raw materials include the following components in parts by weight: 22.5 kg of polyvinyl chloride, 12.5 kg of acrylonitrile-styrene copolymer , polybenzimidazole 7.5kg, microcrystalline paraffin 1.5kg, modified alkali-free glass fiber 4kg, modified Lycra fiber 4.5kg.

[0040]Wherein, the modified alkali-free glass fiber is alkali-free glass fiber double-modified by nano-titanium dioxide and potassium permanganate, and its specific modification method is: first soak the alkali-free glass fiber in high manganese In the potassium permanganate solution, the mass of the alkali-free glass fiber soaked in it is 10% of the mass of the potassium permanganate solution, and then the soaked alkali-free glass fiber is dried, and the nano-titanium dioxide is adsorbed on its surface by electrostatic adsorption technology , wherein the adsorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com