Production technology of hot-melt waterproof roll

A technology of waterproofing membrane and production process, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of insufficient tensile strength and uneven thickness, and achieve the effect of smooth thickness and inhibiting foam generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

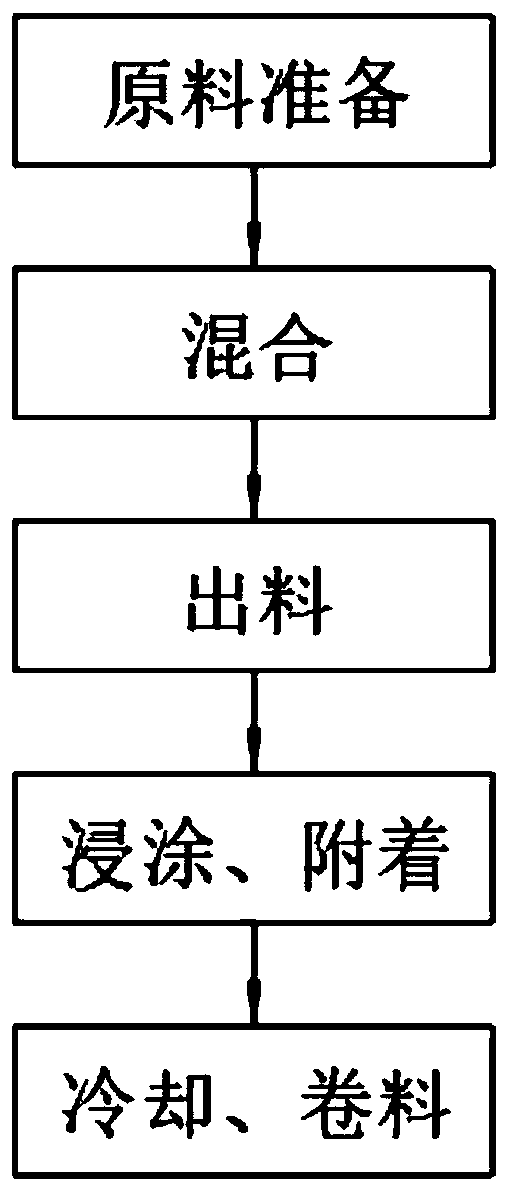

[0026] A production process of a hot-melt waterproof coiled material, comprising the steps of:

[0027] Step 1: Raw material preparation: The raw materials are recorded by the number of parts: 100 parts of asphalt, 1 part of softener, 40 parts of thermoplastic polyurethane, 7 parts of thickener, 1 part of defoamer, and 16 parts of filler; the asphalt is 10# petroleum asphalt One or more of 70# petroleum asphalt and 90# petroleum asphalt; the softener is the second-line oil reduction or the third-line oil reduction; the thickener is one or more of sodium-based bentonite, organic bentonite, and diatomaceous earth The defoaming agent is methyl silicone oil or polysiloxane; the filler is calcium powder or stone powder; the softener is an auxiliary agent used to improve the processing performance and use performance of rubber, which can increase the plasticity of the rubber material and reduce the rubber The viscosity of the material and the temperature during mixing can improve th...

Embodiment 2

[0033] The production process of embodiment 2 is substantially equal to that of embodiment 1, and the difference is that the raw materials are recorded by the number of parts: 110 parts of asphalt, 3 parts of softening agent, 50 parts of thermoplastic polyurethane, 11 parts of thickener, 2 parts of defoamer, filling 21 doses.

Embodiment 3

[0035] The production process of embodiment 3 is substantially equal to that of embodiment 1, and the difference is that the raw materials are recorded according to the number of parts: 120 parts of asphalt, 6 parts of softening agent, 60 parts of thermoplastic polyurethane, 15 parts of thickener, 3 parts of defoamer, filling 26 doses.

[0036] Raw material ratio table in different embodiments

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com