Watch washing method

A watch and cleaning agent technology, which is applied in the field of daily chemicals, can solve a lot of rinsing work, cleaning troubles and other problems, and achieve the effect of improving cleaning efficiency, high cleaning efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

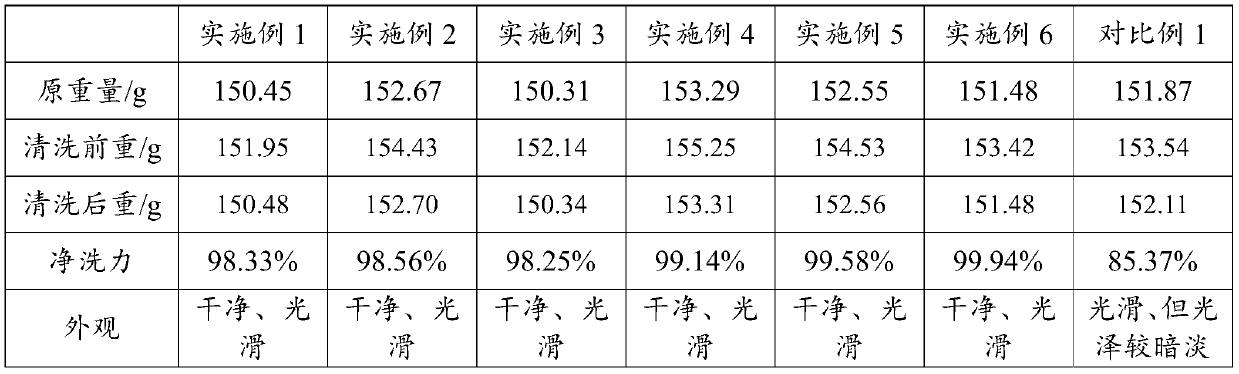

Examples

preparation example Construction

[0039] The preparation method of the alkaline electrolyzed water comprises:

[0040] 1. Prepare sodium carbonate solution and purified water;

[0041] 2. Sodium carbonate solution is circulated in the anode chamber, and pure water is circulated in the cathode chamber;

[0042] 3. After electrification and electrolysis, the finished product of alkaline electrolyzed water is obtained in the cathode chamber;

[0043] Wherein, the mass concentration of the sodium carbonate solution is 10-40%, and the total soluble solids of the pure water is less than 12mg / L;

[0044] The pH of the alkaline electrolyzed water is 11.8-13.0, and the ORP is -500--1500mV.

[0045] The present invention prepares alkaline electrolyzed water with a pH of 11.8 to 13.0 and an ORP of -500 to -1500mV as a cleaning agent through a specific preparation process. There are a large amount of small molecular cluster water in this electrolyzed water. Molecular group water has a strong penetrating power, which ca...

Embodiment 1

[0063] detergent

[0064] 100 parts of alkaline electrolyzed water, its pH is 11.8, ORP is -500mV;

[0065] Preparation method of alkaline electrolyzed water:

[0066] 1. Prepare sodium carbonate solution and purified water;

[0067] The mass concentration of sodium carbonate solution is 10%, and the TDS of pure water is 12mg / L;

[0068] 2. Sodium carbonate solution is circulated in the anode chamber, and pure water is circulated in the cathode chamber;

[0069] 3. After electrification and electrolysis, the finished product of alkaline electrolyzed water is obtained in the cathode chamber;

[0070] the cleaning method:

[0071] (1) take cleaning agent;

[0072] (2) Put the watch into the cleaning agent and clean it for 0.5 minutes; the cleaning temperature is 20°C;

[0073] (3) Dry the watch;

Embodiment 2

[0075] detergent

[0076] 100 parts of alkaline electrolyzed water, its pH is 12.6, ORP is -850mV;

[0077] Preparation method of alkaline electrolyzed water:

[0078] 1. Prepare sodium carbonate solution and purified water;

[0079] The mass concentration of sodium carbonate solution is 20%, and the TDS of purified water is 5mg / L;

[0080] 2. Sodium carbonate solution is circulated in the anode chamber, and pure water is circulated in the cathode chamber;

[0081] 3. After electrification and electrolysis, the finished product of alkaline electrolyzed water is obtained in the cathode chamber;

[0082] the cleaning method:

[0083] (1) take cleaning agent;

[0084] (2) Put the watch into the cleaning agent and clean it for 1 minute; the cleaning temperature is 20°C;

[0085] (3) Dry the watch;

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com