Anti-static movable floor and production process thereof

A raised floor and production process technology, applied to local raised floors, floors, insulating layers, etc., can solve the problems of Modem, network card malfunction, enhanced anti-static capability of the floor, abnormal printer printing, etc., to achieve replaceability Good, enhanced structural strength, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

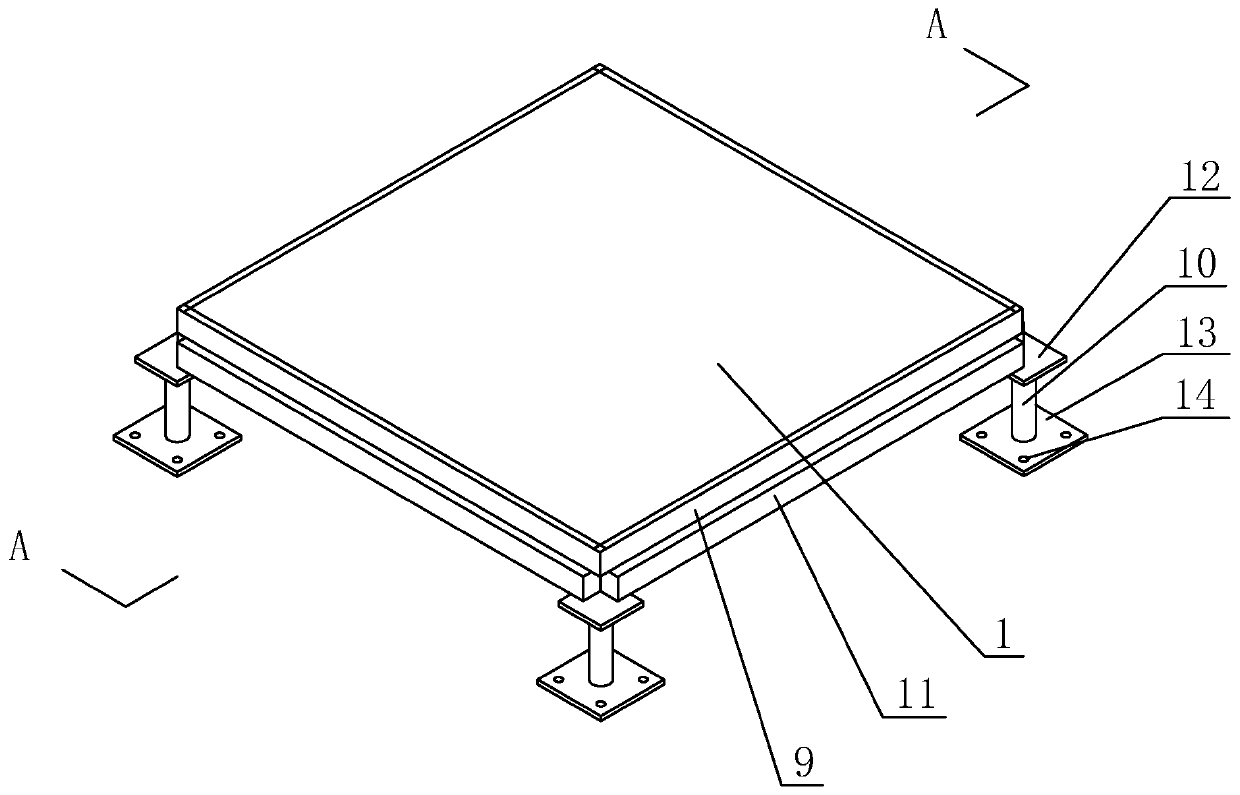

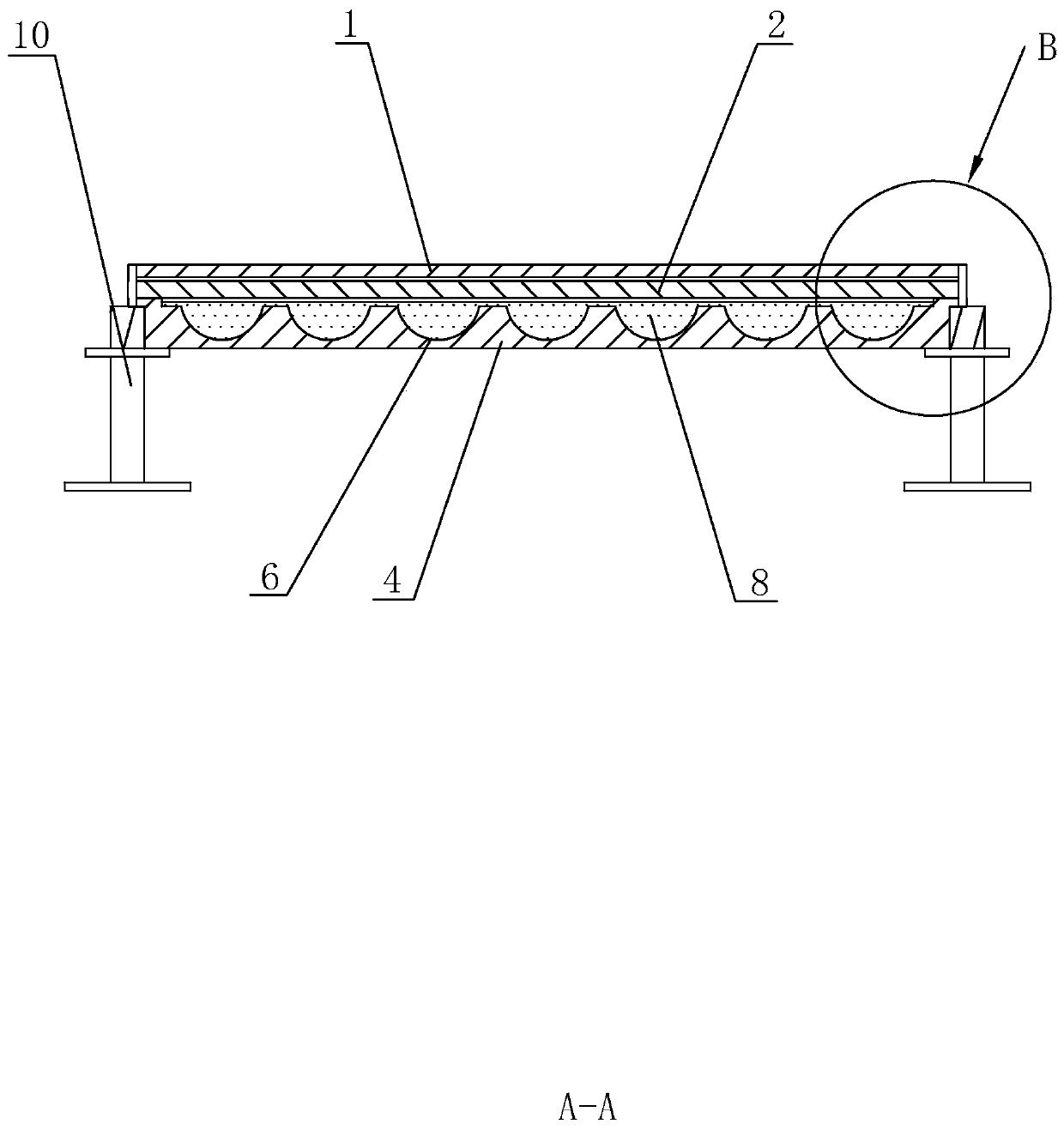

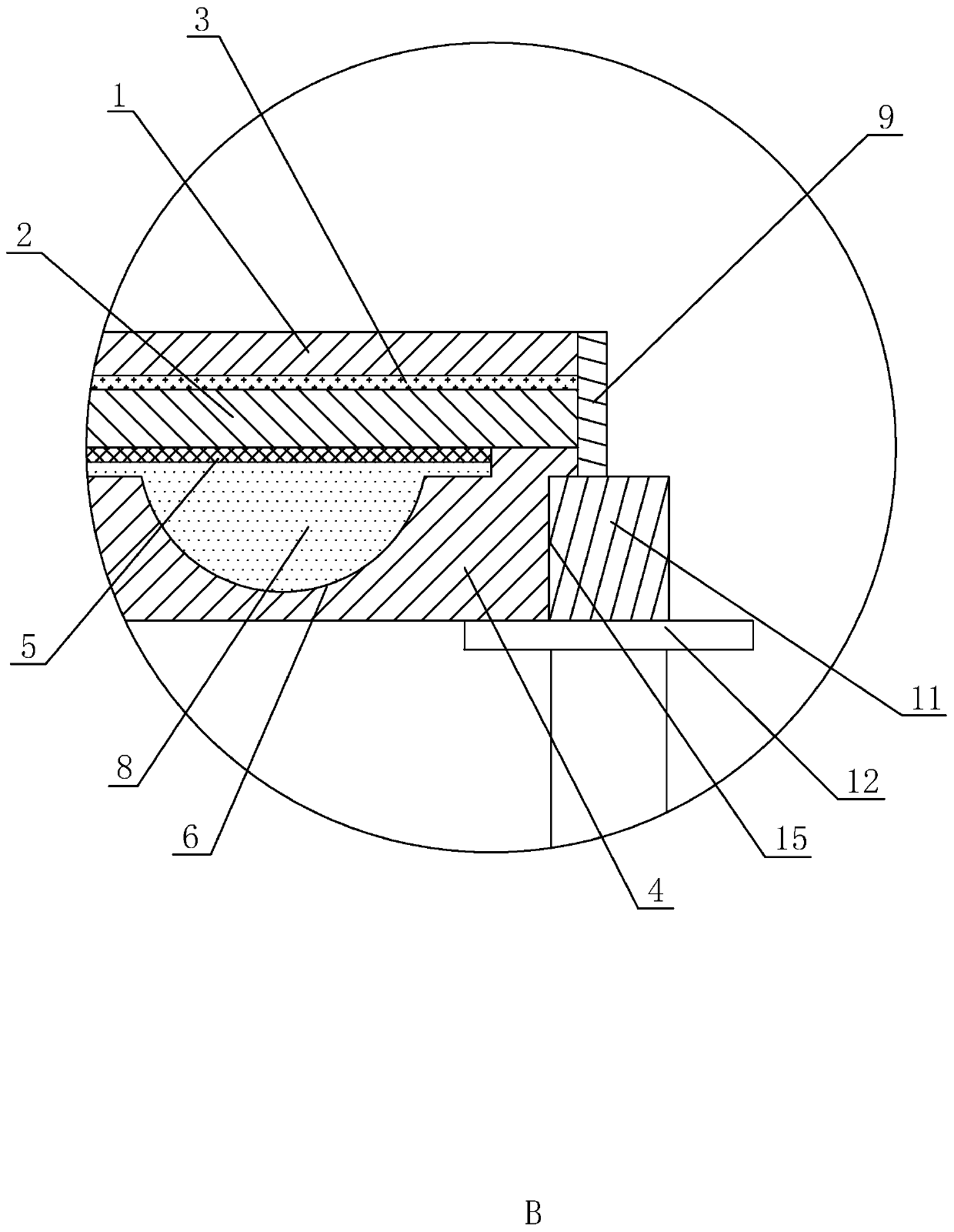

[0043] refer to figure 1 , is an antistatic raised floor disclosed by the present invention, comprising a veneer 1, the material of the veneer 1 is PVC, NPVC, HPL or ceramics, and the veneer 1 is preferably PVC material. According to different installation environments, different materials are used, and PVC materials are more stable and wear-resistant.

[0044] An upper steel plate 2 is provided on the lower surface of the veneer 1 , and the veneer 1 and the upper steel plate 2 are bonded and fixed by conductive glue 3 . The conductive glue 3 plays a role of preventing charge accumulation. The upper steel plate 2 is made of high-quality cold-rolled steel plate, which is formed by one stamping and has high dimensional accuracy. The lower end of the upper steel plate 2 is provided with a lower steel plate 4 welded and fixed to its surrounding edges. The lower steel plate 4 is a deep-stretched cold-rolled steel plate. The lower steel plate 4 faces the upper steel plate 2 and is...

Embodiment 2

[0048] A production process for an antistatic raised floor, comprising the steps of:

[0049]Step 1, the upper steel plate 2 and the lower steel plate 4 are stamped and formed by one-time stamping by adopting a cold rolling process. The upper steel plate 2 and the lower steel plate 4 are cold-rolled steel plates with high dimensional accuracy and high structural strength. The outer surfaces of the upper steel plate 2 and the lower steel plate 4 are sprayed with antistatic paint. Thus, the antistatic ability of the upper steel plate 2 and the lower steel plate 4 is further improved.

[0050] Step 2: Fill the dimple-shaped groove 6 of the lower steel plate 4 with Portland foamed cement 8 and cover the upper steel plate 2 until the hollow space between the lower steel plate 4 and the upper steel plate 2 is completely full. The peripheral sides of the upper steel plate 2 and the lower steel plate 4 are welded together. 425# Portland foamed cement 8 is used, and the cement stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com