Double-leaf suspension door of permanent magnet synchronous linear motor

A permanent magnet synchronous linear and permanent magnet synchronous motor technology, applied in the field of suspension doors, can solve problems such as difficult control, low safety performance, and large movement noise, and achieve the effects of easy push, simple structure, and low wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

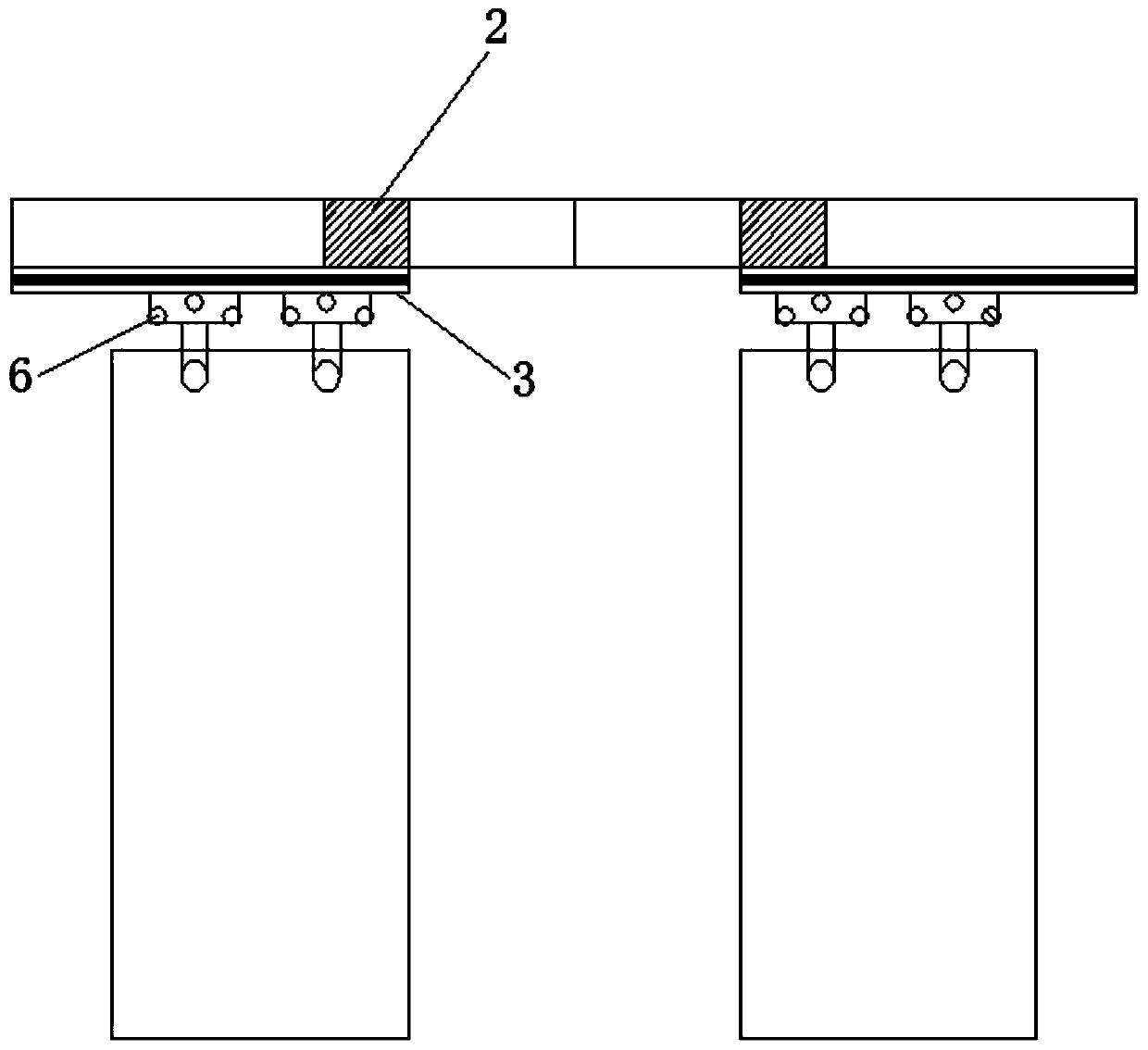

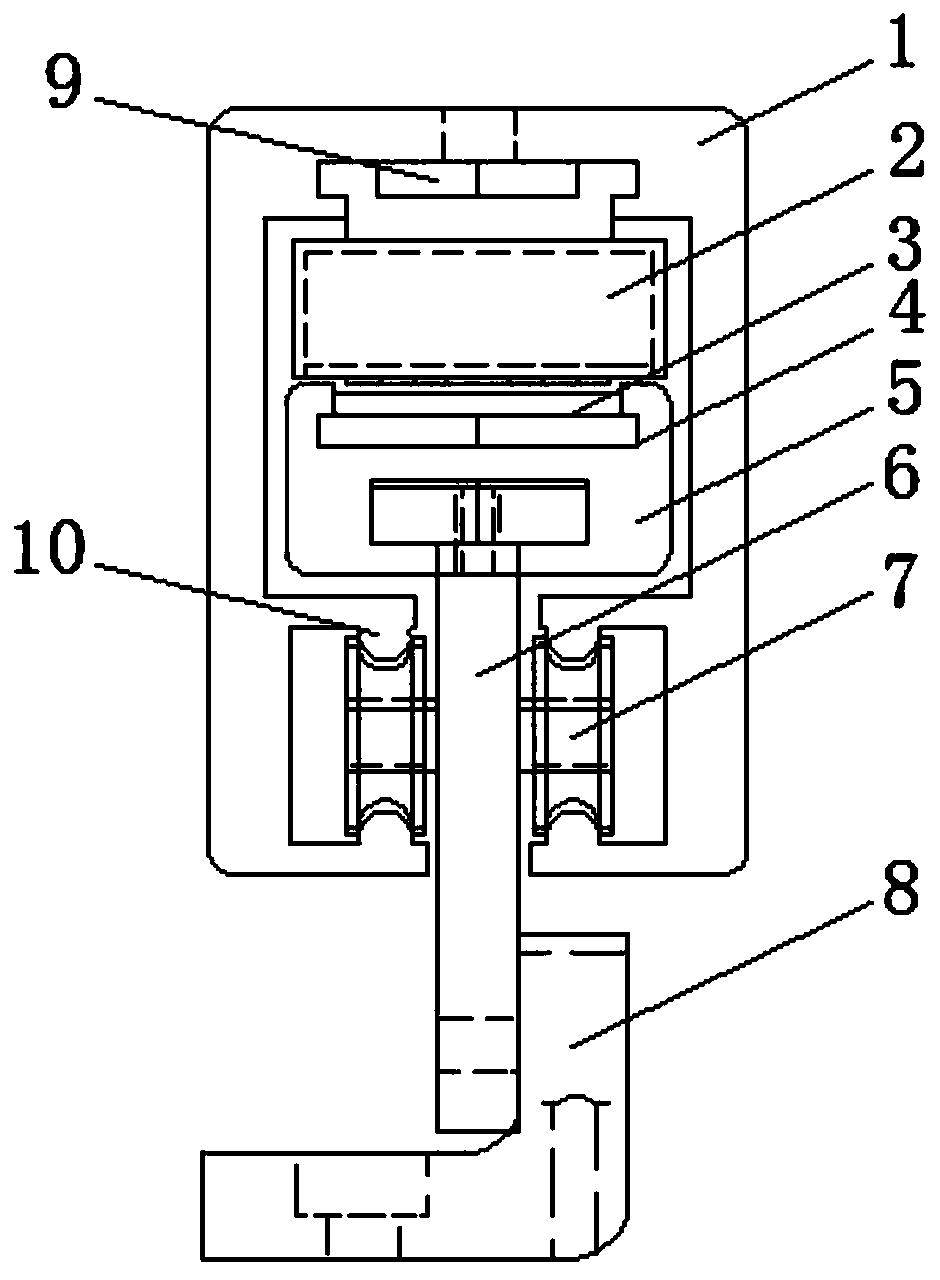

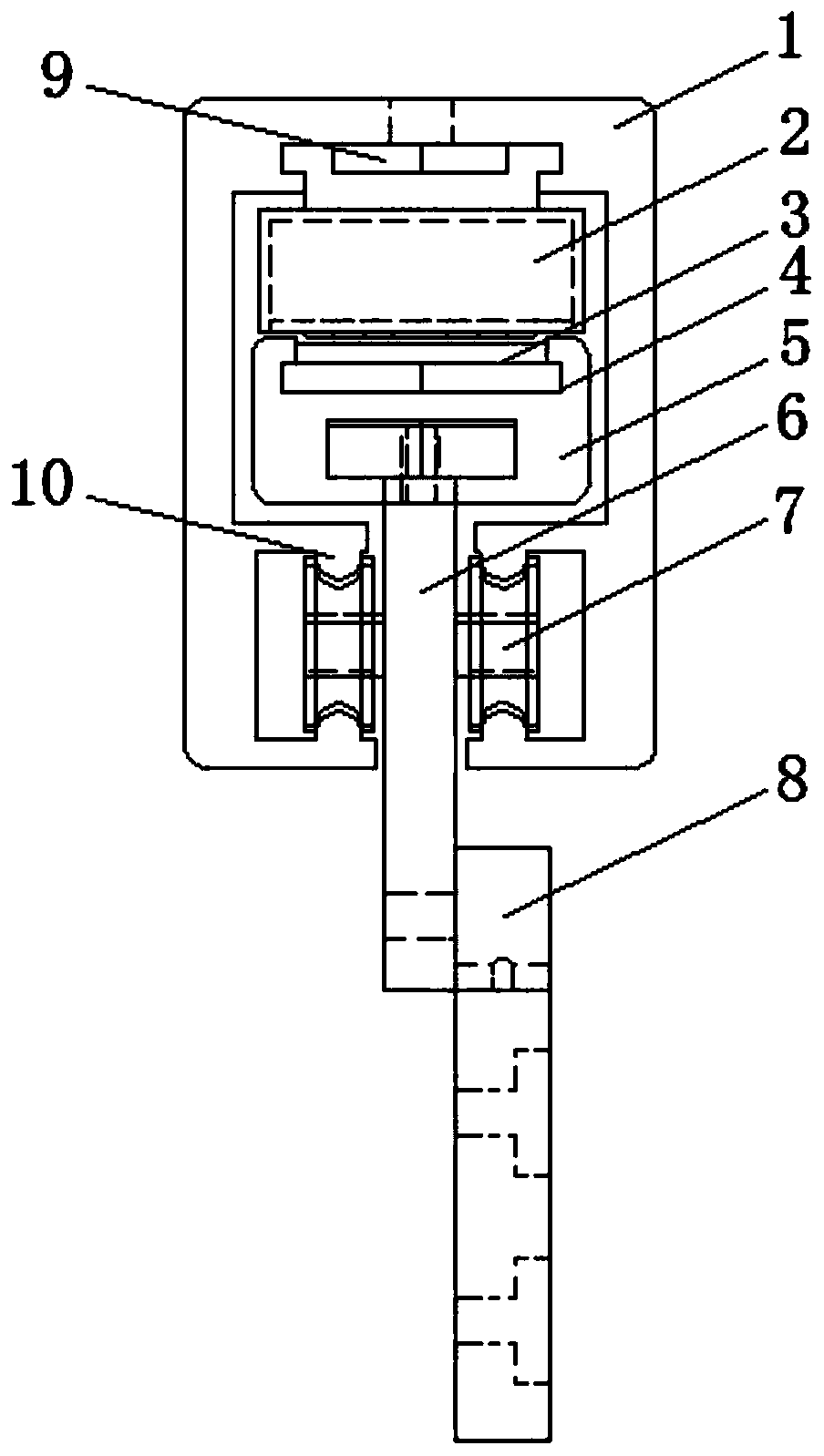

[0034] Such as Figure 1-7.2 As shown, the present invention provides a double-leaf suspension door of a permanent magnet synchronous linear motor, including a permanent magnet synchronous motor, a stator profile 1, a mover profile 5, a roller assembly a6 and a roller assembly b7, a door connector 8 and a linear motor. Intelligent drive control power supply. The permanent magnet synchronous motor includes a primary stator 2, a secondary mover a3 and a secondary mover b4. The primary stator 2 of the permanent magnet synchronous linear motor cooperates with the stator profile 1 through the profile groove, and the two ends are connected by the stator The inner cavity groove of the profile 1 is positioned; the secondary mover a3 and the secondary mover b4 both cooperate with the mover profile 5 through the profile groove, and the two ends are positioned by the inner cavity groove of the stator profile 1, and the primary stator 2 of the permanent magnet synchronous motor Installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com