Yield increasing method for reducing pressure loss in gas well by using compressor

A compressor and internal pressure technology, applied in wellbore/well components, earthwork drilling, fluid production, etc., to achieve the effect of reducing follow-up operating costs, reducing early-stage operating costs, and easy operation management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

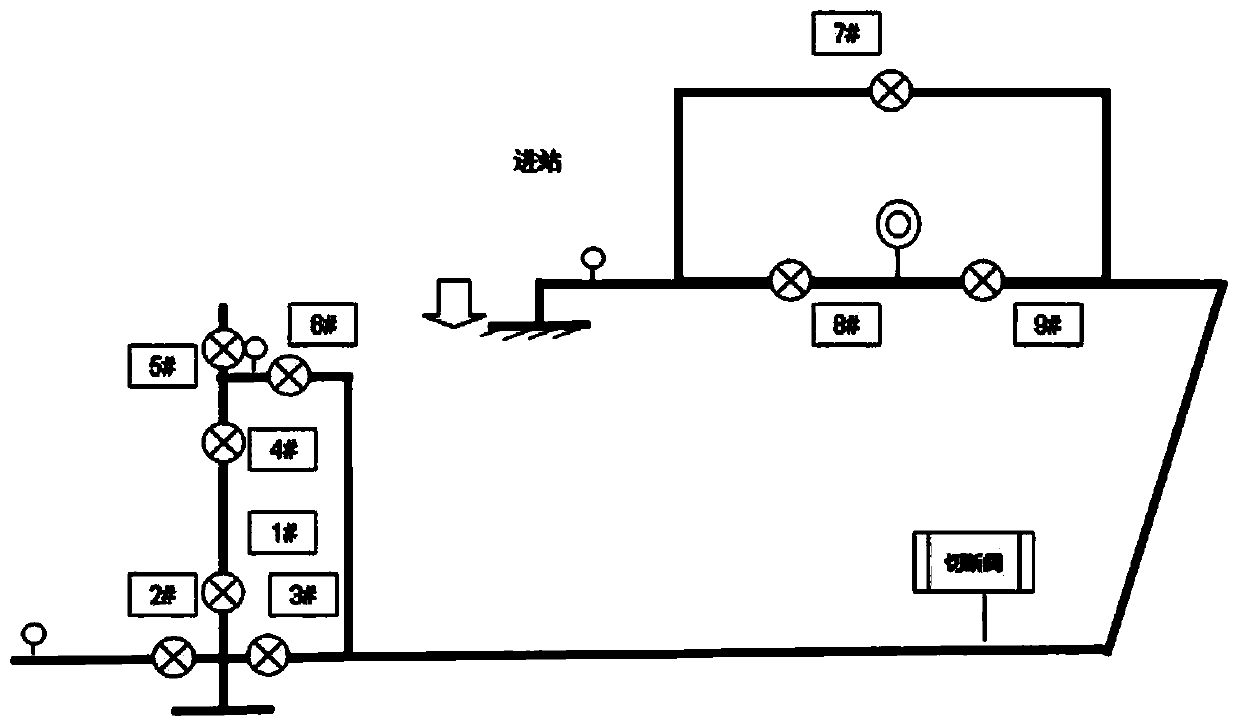

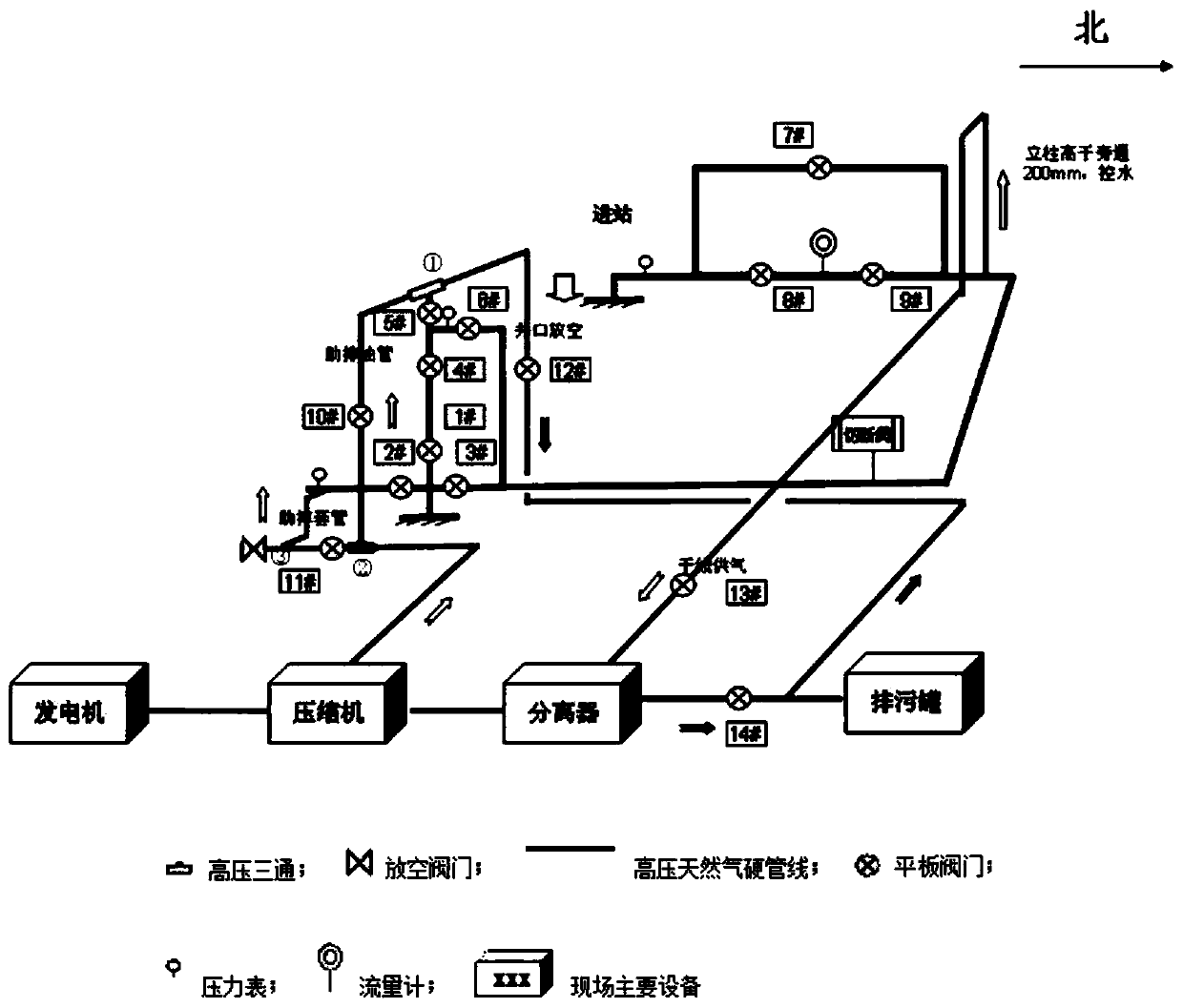

Method used

Image

Examples

Embodiment

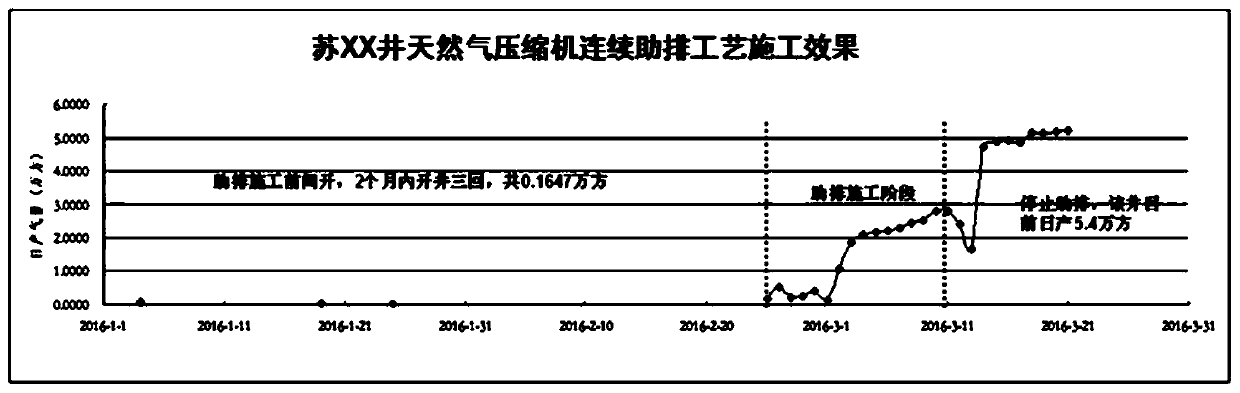

[0076] Well Su XX, a horizontal well, has a horizontal section of 1200m and a bottom vertical depth of 3700m. When the well was in normal production, the daily production level was 70,000 cubic meters per day. On October 19, 2015, due to system maintenance, production was shut down for 12 hours. After the well was opened Unable to self-spray production; adopt annular nitrogen gas lift measures, stop spraying after 7 hours of self-spraying production, and take measures of foam rod and foam discharge agent drainage successively, unable to resume production. On November 18, 2015, the coiled tubing gas lift measures were taken, but self-injection production was still not possible. The liquid level was tested on November 27, 2015, and the depth of the liquid level was 1400 meters.

[0077] From February 23, 2016 to March 9, 2016, Japan invented the production process for a total of 16 days. Before construction, the tubing pressure: 0.87MPa, the casing pressure: 3.83MPa, and the sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com